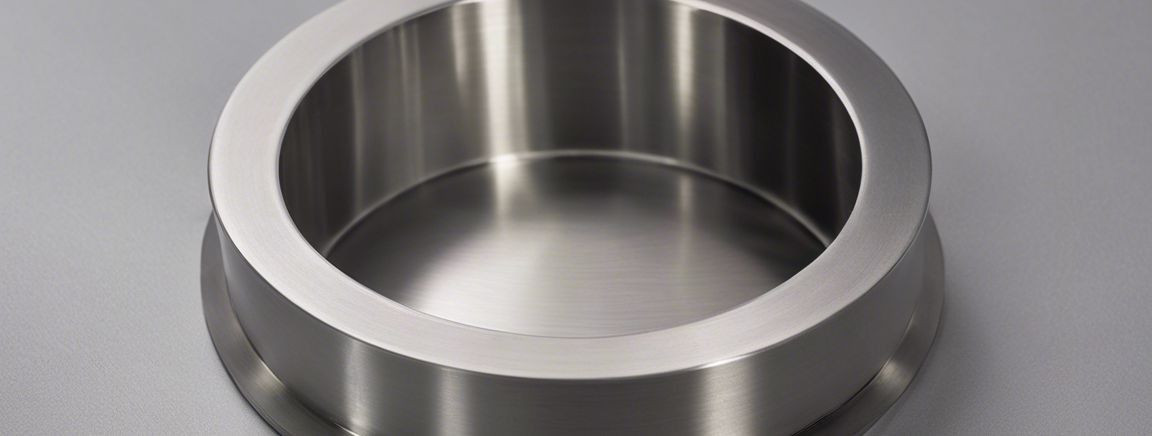

The art of stainless steel polishing: techniques and tips

Stainless steel polishing is a critical process in the manufacturing and construction industries, where the appearance, durability, and corrosion resistance of metal components are paramount. A well-polished stainless steel surface not only enhances aesthetic appeal but also extends the material's lifespan by creating a protective layer against environmental factors.

Stainless steel is an alloy known for its strength and resistance to rust and tarnishing. It contains chromium, which forms a passive layer of chromium oxide, protecting the steel from corrosion. However, to maintain its properties and appearance, regular polishing is essential.

Preparation for Polishing

Before polishing, it's crucial to assess the condition of the stainless steel surface. Identifying any imperfections, such as scratches or dents, will determine the appropriate polishing method and materials required.

Cleaning the stainless steel surface is vital to remove any contaminants that could affect the polishing process. Using appropriate cleaning agents and techniques ensures a clean base for polishing.

Choosing the correct tools and materials for polishing is essential for achieving a high-quality finish. This includes selecting suitable abrasives, polishing compounds, and equipment tailored to the specific requirements of the project.

Polishing Techniques

Manual polishing is a labor-intensive process that involves using hand tools and abrasives to achieve the desired finish. It's often used for smaller projects or intricate areas where precision is crucial.

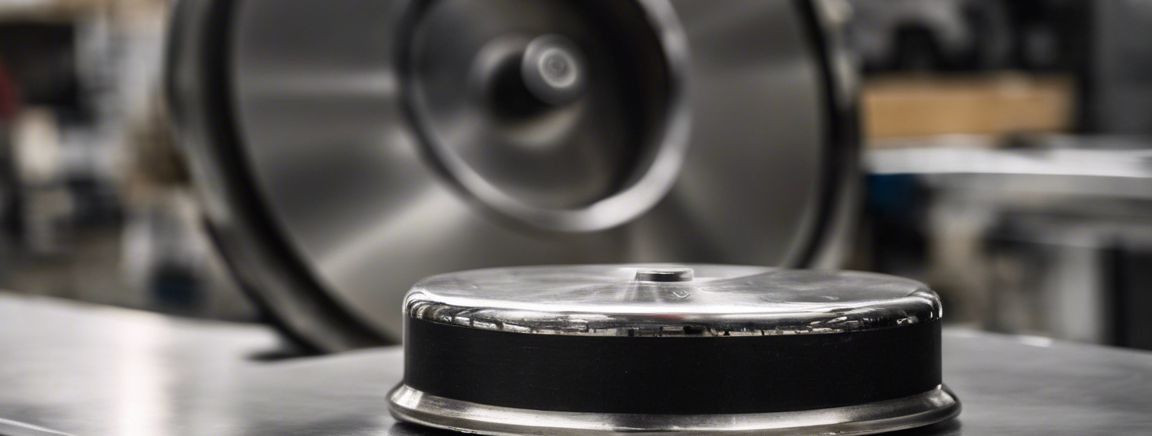

Mechanical polishing utilizes machines and equipment to polish larger surfaces more efficiently. This method is ideal for achieving consistent results on bigger projects.

Electropolishing is an electrochemical process that smoothens and streamlines the metal surface at a microscopic level. It's highly effective for improving the surface finish and corrosion resistance of stainless steel components.

Polishing Tips for Optimal Results

When polishing stainless steel, it's important to work with the grain direction to avoid cross-scratching and maintain the integrity of the surface.

Selecting the right abrasives is crucial for achieving the desired finish. Different grades of abrasives are used depending on the initial condition of the stainless steel and the level of shine required.

After polishing, applying finishing touches such as buffing and cleaning can enhance the overall appearance and protect the surface from future damage.

Maintaining Polished Stainless Steel

Regular cleaning is essential to maintain the polished finish of stainless steel. Using non-abrasive cleaning agents and soft cloths can prevent surface damage and preserve the shine.

Applying protective coatings or sealants can provide an additional layer of defense against corrosion and wear, ensuring the longevity of the polished finish.

Periodic inspection and touch-ups are necessary to address any minor issues before they become significant problems, keeping the stainless steel in pristine condition.

Seeking precision stainless steel polishing services? Contact MEVOLMET GRUPP OÜ for custom solutions that meet the highest industry standards.

Comments (0)