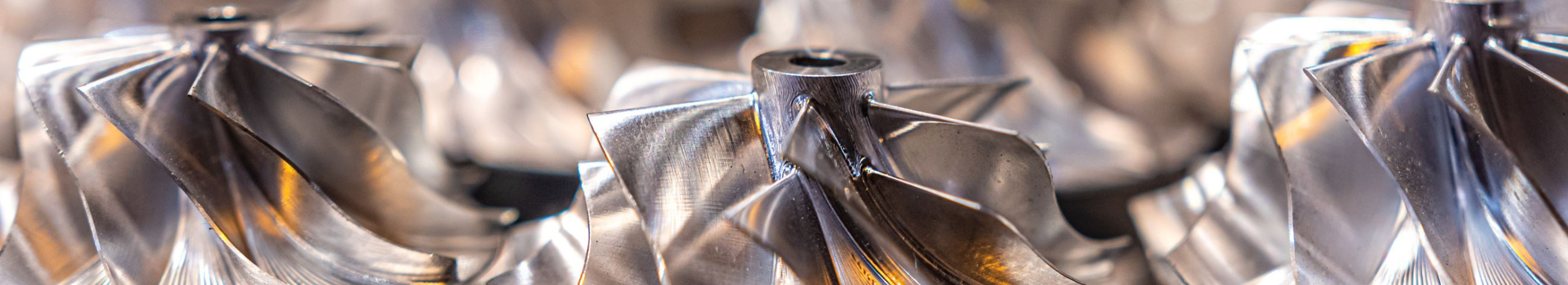

The art of precision metal cutting: techniques and tools

Precision metal cutting is a critical process in the manufacturing and construction industries, where the accuracy and quality of cut metal parts can significantly impact the performance and longevity of the final products. From infrastructure projects to automotive components, precision metal cutting underpins the success of countless industrial applications.

Over the years, metal cutting techniques have evolved from manual labor-intensive processes to highly sophisticated, automated systems. This evolution has been driven by the need for greater precision, efficiency, and the ability to handle complex geometries and materials.

Understanding Metal Cutting Processes

Shearing is a simple yet effective method of cutting straight lines on flat metal stock. It involves the application of a great force to slice the metal, typically using a punch and die.

Laser cutting utilizes a high-powered laser beam to melt, burn, or vaporize material, offering high precision and speed. It is particularly effective for intricate designs and can be used on a variety of metals.

Waterjet cutting employs a jet of water, often mixed with an abrasive substance, to cut through metal. This method generates no heat, preserving the properties of the metal and allowing for the cutting of complex shapes.

Plasma cutting involves ionizing gas to create plasma and then using it to melt metal in a controlled manner. It is well-suited for cutting thick metal plates and is known for its speed.

EDM is a non-traditional cutting method that uses electrical discharges to erode material in a very controlled way. It is ideal for hard metals and complex shapes that are difficult to machine with traditional methods.

Key Tools in Precision Metal Cutting

The choice of cutting tools and materials is paramount in achieving the desired precision. Tools must be selected based on the material being cut and the required finish.

CNC machines are the cornerstone of modern precision metal cutting. They provide unparalleled accuracy and repeatability, and can be programmed to perform complex cuts with minimal human intervention.

To ensure the highest standards of precision, quality control instruments such as calipers, micrometers, and coordinate measuring machines (CMMs) are used to verify dimensions and tolerances.

Best Practices in Precision Metal Cutting

Choosing the right material for the job is crucial, as different metals respond differently to various cutting processes. Material selection can affect the cutting speed, finish quality, and overall cost.

Designing parts with manufacturability in mind can greatly enhance the efficiency and cost-effectiveness of the cutting process. This involves considering factors such as material, geometry, and tolerances during the design phase.

Regular maintenance of cutting equipment is essential to ensure consistent precision. Additionally, strict adherence to safety protocols protects workers from the hazards associated with metal cutting operations.

Comments (0)