Laser cutting vs. traditional methods: what's best for your project?

Traditional cutting methods have been the backbone of manufacturing and prototyping for decades. These methods, including sawing, milling, and waterjet cutting, rely on physical contact with the material, often requiring manual adjustments and tool changes. While these techniques have proven effective for a range of applications, they come with limitations in terms of precision, speed, and material versatility.

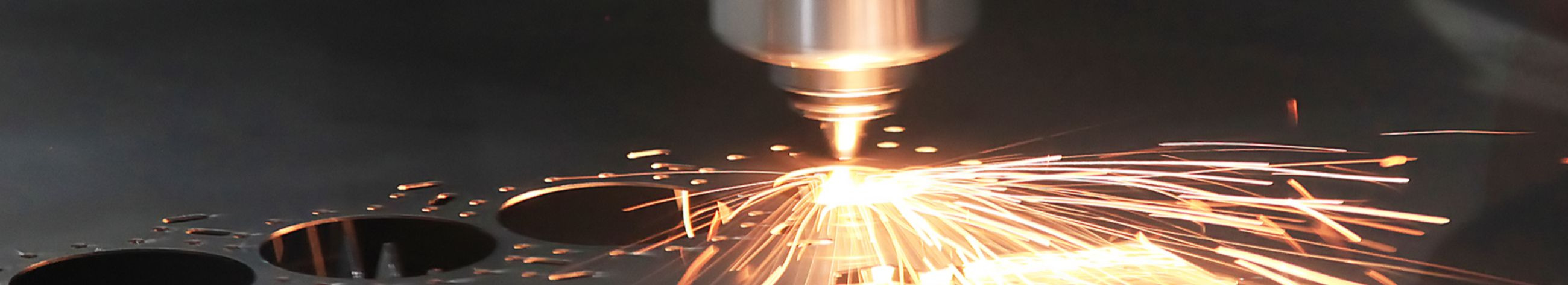

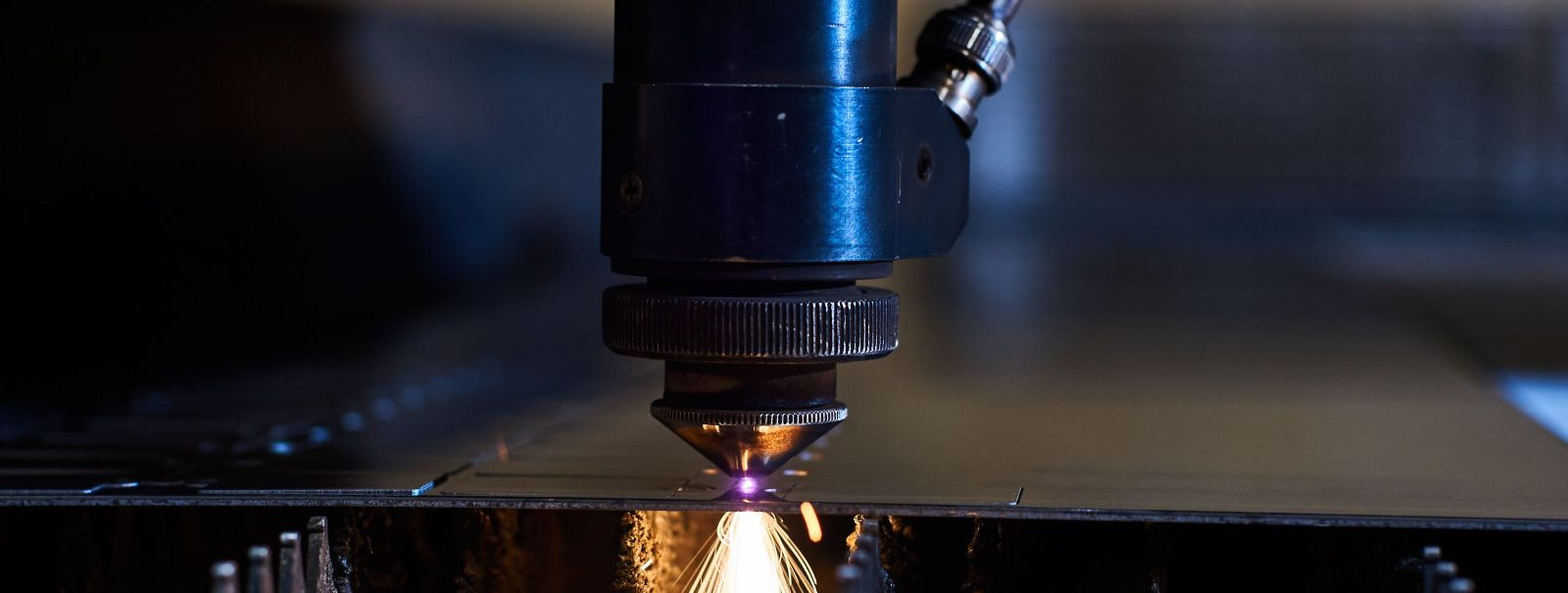

Laser cutting, a technology that emerged in the latter half of the 20th century, has revolutionized the way we approach fabrication. Utilizing a high-powered laser beam, this method offers unparalleled precision and allows for intricate designs that were once deemed impossible. As a non-contact process, it minimizes material waste and reduces the need for post-processing.

Comparing Laser Cutting to Traditional Methods

Laser cutting stands out for its exceptional accuracy and precision. The laser beam can be focused to a pinpoint, allowing for cuts as fine as a fraction of a millimeter. This level of detail is unmatched by traditional methods, which are often subject to the limitations of blade thickness and human error.

One of the advantages of laser cutting is its ability to handle a diverse range of materials, including metals, plastics, wood, and composites. Traditional methods may require different tools or machines to work with various materials, whereas a laser cutter can seamlessly switch between tasks without the need for additional equipment.

The speed of laser cutting is another significant benefit. Projects that would take hours using traditional methods can be completed in minutes with a laser cutter. This efficiency not only saves time but also contributes to a lower cost of operation in the long run.

When it comes to complex designs and intricate details, laser cutting provides a clear advantage. Traditional cutting methods are often limited by the tool's ability to maneuver and the risk of material breakage. Laser cutting, on the other hand, excels in producing complex geometries with clean, crisp edges.

While the initial investment in laser cutting technology may be higher than traditional equipment, the long-term savings are significant. Reduced labor costs, lower material waste, and faster production times all contribute to a more cost-effective process for high-volume or custom projects.

Safety is a paramount concern in any manufacturing environment. Laser cutters, being a non-contact process, reduce the risk of accidents associated with manual cutting methods. Additionally, laser cutting produces less airborne debris and contaminants, making it a more environmentally friendly option.

Choosing the Right Method for Your Project

Before deciding on a cutting method, it's essential to assess the specific requirements of your project. Consider the level of detail needed, the type of material, and the desired turnaround time.

The choice of cutting technology can also be influenced by the material you intend to use. Some materials may be better suited to traditional methods, while others can benefit from the precision of laser cutting.

The scale of production is another critical factor. For small batches or one-off prototypes, laser cutting might be the most efficient choice. In contrast, traditional methods might be more cost-effective for large-scale production runs.

Performing a cost-benefit analysis can help determine the most economical approach for your project. Factor in the cost of materials, labor, and equipment maintenance when making your decision.

Finally, consider the availability of expertise and equipment. If you have access to advanced laser cutting services, like those offered by 3DKODA OÜ, it might be advantageous to leverage this technology for your project.

Comments (0)