Installation of Biomass-Fueled Boiler Houses: A Sustainable Energy Solution

As global industries continue their shift towards greener, more sustainable energy solutions, the demand for biomass-fueled boiler houses has significantly increased. Biomass boilers, powered by renewable organic materials such as wood chips, pellets, and agricultural residues, offer a reliable and environmentally friendly alternative to traditional fossil fuel-based heating systems. The installation of these biomass-fueled boiler houses requires expert planning, precise execution, and ongoing maintenance to ensure efficient and long-lasting performance.

The Benefits of Biomass-Fueled Boiler Houses

Biomass boilers provide a range of benefits for industrial and energy companies. Not only do they help reduce carbon emissions, but they also offer cost savings over time due to the use of renewable and often locally sourced fuel. Additionally, many governments offer incentives and subsidies for companies that invest in renewable energy, making biomass a financially attractive option.

In terms of reliability, modern biomass boiler systems are designed to provide consistent heat and steam production, comparable to traditional boilers. With proper installation and maintenance, these systems can operate at high efficiency, offering a sustainable solution for heating large industrial facilities or even entire communities.

Key Considerations in Biomass Boiler Installation

When installing a biomass-fueled boiler house, several important factors must be considered to ensure optimal performance and longevity of the system:

Site Assessment

A detailed site assessment is essential to determine the appropriate size and type of biomass boiler. Factors such as the available space, proximity to fuel sources, and the heating demands of the facility all play a critical role in the planning process.Boiler System Design

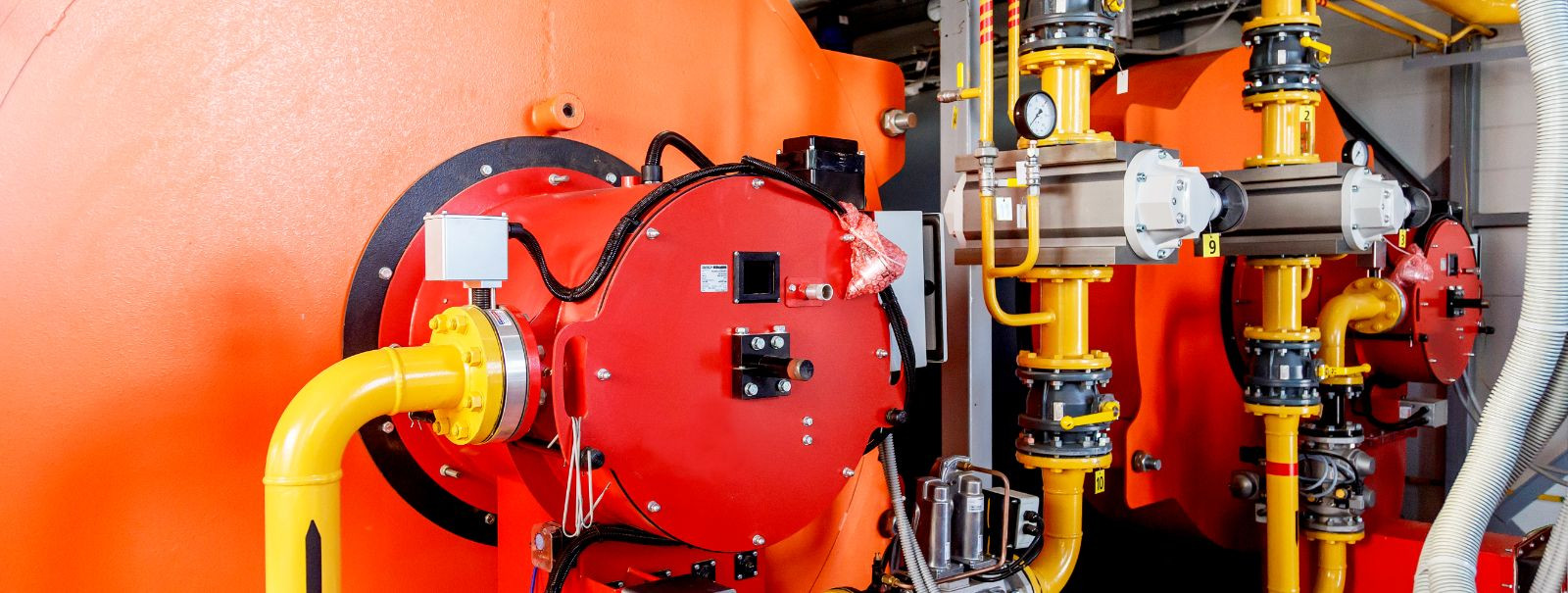

The design of the boiler system must align with the specific needs of the facility. This includes selecting the right type of boiler, configuring the fuel handling system, and integrating any necessary auxiliary components like heat exchangers or emissions control equipment.Fuel Handling and Storage

Biomass fuel needs to be properly stored and transported to the boiler. This requires the installation of a well-designed fuel handling system that can efficiently transport fuel from storage to the combustion chamber. Ensuring a steady and reliable fuel supply is key to maximizing the boiler's efficiency.Emissions Control

While biomass is a cleaner energy source compared to fossil fuels, proper emissions control systems should be in place to meet environmental regulations. Filters, scrubbers, and other technologies can help minimize particulate emissions and ensure that the plant operates in compliance with local and international standards.Professional Installation

The installation of a biomass boiler house is a complex process that requires expertise in mechanical and electrical engineering. Professional installation ensures that all components are correctly integrated, allowing the system to run smoothly from the start.

Ongoing Maintenance for Longevity

Once installed, regular maintenance is critical to ensuring the long-term efficiency and reliability of the biomass boiler. Routine checks and servicing, including cleaning the combustion chamber, inspecting the fuel handling system, and monitoring emissions, help prevent costly breakdowns and extend the lifespan of the equipment.

Preventative maintenance not only reduces the risk of operational downtime but also ensures that the system operates at peak efficiency, providing consistent heat and steam production with minimal environmental impact.

Conclusion

The installation of biomass-fueled boiler houses represents a powerful step towards sustainability for industrial and energy companies. With the growing focus on reducing carbon emissions and embracing renewable energy sources, biomass boilers offer a viable and efficient solution. However, successful implementation requires careful planning, expert installation, and ongoing maintenance to ensure long-term performance and sustainability.

Investing in biomass boiler systems can significantly reduce a company's environmental footprint while also offering substantial long-term cost savings, making it a smart choice for businesses looking to contribute to a cleaner, greener future.

Kommentaarid (0)