Maintenance and Repair of Boiler Systems: Ensuring Efficiency and Longevity

Boilers are essential components in various industries, providing heat and steam for processes ranging from manufacturing to energy production. Regular maintenance and timely repairs are crucial to ensuring that these systems operate efficiently and safely. Neglecting boiler maintenance can lead to reduced performance, increased energy costs, and even catastrophic failures. This article explores the importance of boiler maintenance and repair, key practices, and the benefits of a proactive approach.

The Importance of Boiler Maintenance

Efficiency Optimization

Regular maintenance helps keep boiler systems operating at peak efficiency. Over time, factors such as scale buildup, soot accumulation, and wear on components can reduce efficiency. Routine checks and cleaning ensure that the boiler operates smoothly, resulting in lower energy consumption and reduced operating costs.Safety Assurance

Boilers operate under high pressure and temperature, making safety a primary concern. Regular maintenance checks help identify and address potential safety hazards, such as leaks, pressure irregularities, and faulty controls. Adhering to safety protocols not only protects personnel but also complies with regulatory standards.Prolonged Equipment Lifespan

Just like any other machinery, boilers require care to extend their operational lifespan. Preventative maintenance, including inspections and timely repairs, can significantly reduce wear and tear on components, ultimately leading to longer-lasting equipment.Reduced Downtime

Unplanned downtime due to boiler failures can disrupt production and lead to financial losses. Regular maintenance allows for the identification of potential issues before they escalate, reducing the risk of unexpected breakdowns and the costly downtime associated with them.

Key Maintenance Practices

Regular Inspections

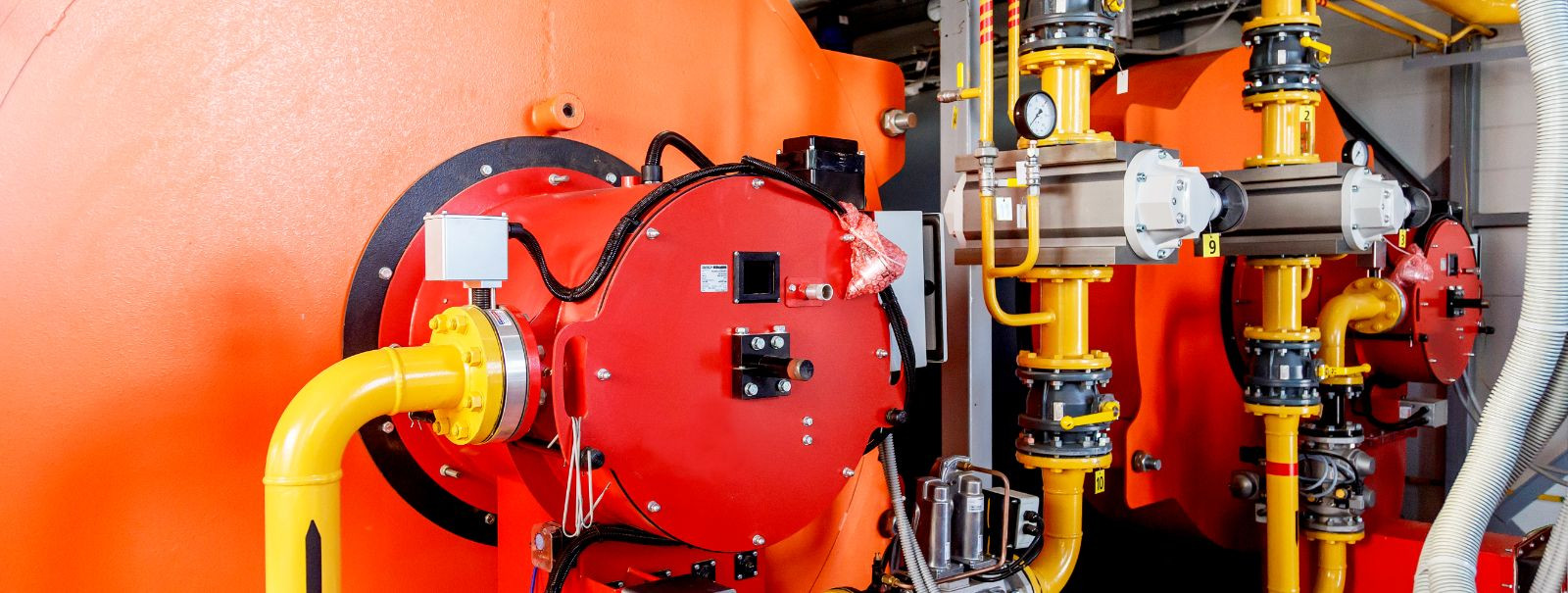

Routine inspections are the foundation of effective boiler maintenance. These should include checks on key components such as burners, heat exchangers, and safety valves. Inspecting for signs of wear, leaks, and corrosion is essential to maintaining boiler integrity.Cleaning

Regular cleaning of the boiler and its components, including the combustion chamber and flue gas pathways, is vital for optimal performance. Removing soot, scale, and other deposits enhances heat transfer efficiency and minimizes the risk of overheating.Water Treatment

The quality of water used in the boiler significantly affects its performance and longevity. Implementing a water treatment program can prevent scale buildup and corrosion, protecting the boiler’s internal components and ensuring efficient operation.Calibration of Controls

Properly calibrated controls are essential for maintaining the desired operating conditions. Regular checks and adjustments of pressure, temperature, and flow controls ensure that the boiler operates within safe and efficient parameters.Emergency Repairs

In the event of a malfunction, quick and effective repairs are crucial. Having a reliable maintenance team available for emergency repairs can minimize downtime and restore operations promptly.

The Benefits of Proactive Maintenance

Cost Savings

Investing in regular maintenance is often more cost-effective than waiting for equipment to fail. Proactive maintenance helps avoid costly repairs, operational disruptions, and inefficient energy usage.Improved Reliability

A well-maintained boiler system is less likely to experience unexpected failures, leading to more reliable operations and increased confidence among stakeholders.Enhanced Performance

Regular maintenance ensures that the boiler operates at optimal performance levels, leading to improved energy efficiency and reduced environmental impact.Compliance and Reputation

Adhering to maintenance schedules and safety regulations ensures compliance with industry standards. A commitment to safety and efficiency enhances a company’s reputation and can be a significant competitive advantage.

Conclusion

The maintenance and repair of boiler systems are critical components of efficient and safe industrial operations. By implementing a proactive maintenance strategy that includes regular inspections, cleaning, water treatment, and emergency repairs, companies can optimize performance, enhance safety, and prolong the lifespan of their boiler systems.

Investing in boiler maintenance is not just about compliance; it’s about ensuring that your operations run smoothly and efficiently. With the right maintenance practices in place, businesses can focus on their core operations while enjoying the peace of mind that comes from knowing their boiler systems are well cared for.

Kommentaarid (0)