5 signs your industrial automation needs an upgrade

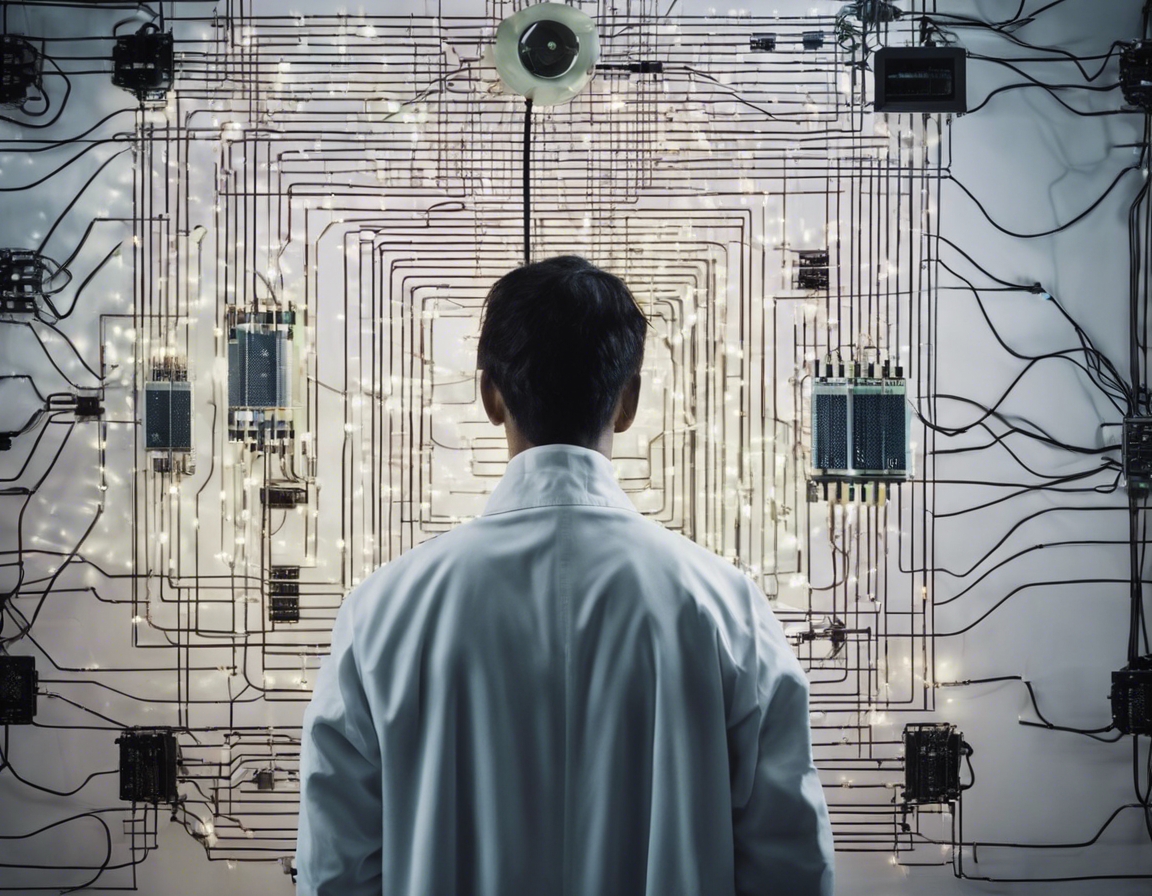

Industrial automation systems are the backbone of modern manufacturing and production facilities. However, as technology advances, systems that were once cutting-edge can become obsolete, leading to inefficiencies and potential risks. Recognizing the signs that your industrial automation needs an upgrade is crucial for maintaining a competitive edge and ensuring operational excellence.

Understanding the Importance of Industrial Automation Upgrades

Automation systems streamline processes, reduce human error, and enhance productivity. They are integral to the success of any industrial operation. Keeping these systems up-to-date is essential for achieving optimal performance and staying ahead in the market.

Modern automation solutions offer improved reliability, efficiency, and flexibility. They can adapt to changing market demands and integrate with emerging technologies, providing a significant return on investment.

Sign #1: Frequent Breakdowns and Downtime

Consistent equipment failures and unplanned downtime can indicate that your automation system is no longer reliable. It's essential to analyze these patterns to determine if an upgrade is necessary.

Downtime not only disrupts production but also incurs significant costs. Upgrading your automation system can reduce these occurrences and save your business money in the long run.

Sign #2: Incompatibility with New Technologies

As new technologies emerge, older automation systems may struggle to integrate with them. This can limit your ability to adopt innovative solutions that could enhance your operations.

Embracing new technologies can lead to improved processes and products. An upgraded automation system can seamlessly incorporate these advancements, keeping your business at the forefront of industry trends.

Sign #3: Decreased Efficiency and Productivity

Monitoring key performance indicators (KPIs) can reveal a decline in efficiency and productivity. If your current system is hindering performance, it may be time to consider an upgrade.

A lag in productivity can put you behind competitors. Upgrading your automation system can help you regain your competitive advantage by optimizing operations.

Sign #4: Safety Concerns and Compliance Issues

Automation systems must comply with strict safety standards. An outdated system could pose risks to employees and lead to compliance violations.

Ignoring safety and compliance can have serious legal and ethical consequences. Upgrading your system helps ensure that you meet all regulatory requirements and protect your workforce.

Sign #5: Limited Data Collection and Analysis Capabilities

In the era of Industry 4.0, data collection and analysis are vital for informed decision-making. An outdated automation system may lack the capability to effectively gather and utilize data.

With an upgraded system, you can harness the power of data analytics to drive strategic business decisions and maintain a competitive edge.

Comments (0)