The ultimate guide to preventive electrical maintenance

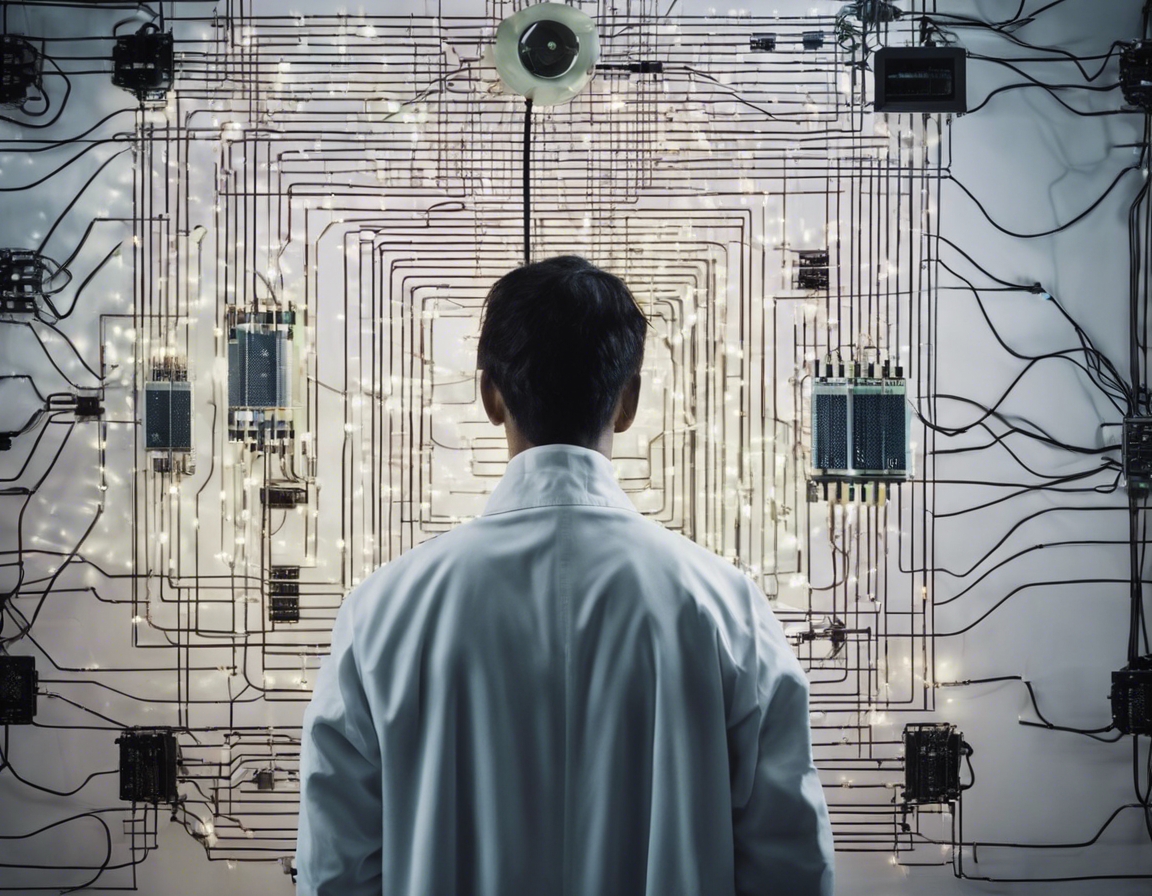

Preventive electrical maintenance is a strategic approach that involves the regular inspection, testing, and servicing of electrical equipment to prevent failures before they occur. It's a proactive measure that aims to ensure the reliability and efficiency of electrical systems, which are the backbone of industrial operations.

In industrial facilities and manufacturing plants, electrical systems are critical to daily operations. Unplanned downtime due to equipment failure can result in significant financial losses and safety risks. Preventive maintenance is essential for maintaining continuous operation, ensuring safety, and optimizing the performance of electrical systems.

Key Components of Preventive Electrical Maintenance

Conducting regular inspections and tests helps identify potential issues before they escalate. This includes checking for wear and tear, ensuring connections are tight, and verifying the integrity of insulation.

Cleaning electrical components prevents the buildup of dust and debris that can cause overheating and failures. Calibration ensures that instruments and controls are operating within their specified parameters.

Thermal imaging is a non-invasive technique that detects hot spots in electrical systems, which are often precursors to electrical faults. This analysis helps in early detection and prevention of potential problems.

Proper grounding and bonding are vital for the safety of electrical systems. Regular checks ensure that these safety measures are effective and up to code.

Developing a Preventive Maintenance Plan

An initial assessment of the electrical systems is crucial to understand their condition and to identify any immediate concerns that need to be addressed.

A well-structured maintenance schedule is the cornerstone of an effective preventive maintenance program. It outlines when each component should be serviced to prevent disruptions.

Meticulous documentation and record-keeping are essential for tracking the history of maintenance activities, which aids in future planning and compliance with regulations.

Best Practices for Preventive Electrical Maintenance

Ensuring that maintenance personnel are well-trained and follow strict safety procedures is critical to the success of any preventive maintenance program.

Using the appropriate tools and equipment for maintenance tasks ensures that the work is done efficiently and safely.

Electrical standards and regulations are constantly evolving. Staying informed and compliant with these standards is necessary for a successful maintenance strategy.

Benefits of Preventive Electrical Maintenance

Preventive maintenance significantly reduces the likelihood of unexpected downtime and equipment failures, saving time and money.

Regular maintenance extends the lifespan of electrical equipment, delaying the need for costly replacements.

By adhering to preventive maintenance practices, facilities can improve safety for workers and ensure compliance with industry regulations.

Well-maintained electrical systems operate more efficiently and reliably, which is crucial for the productivity of any industrial operation.

Comments (0)