5 signs your hydraulic pump needs immediate repair

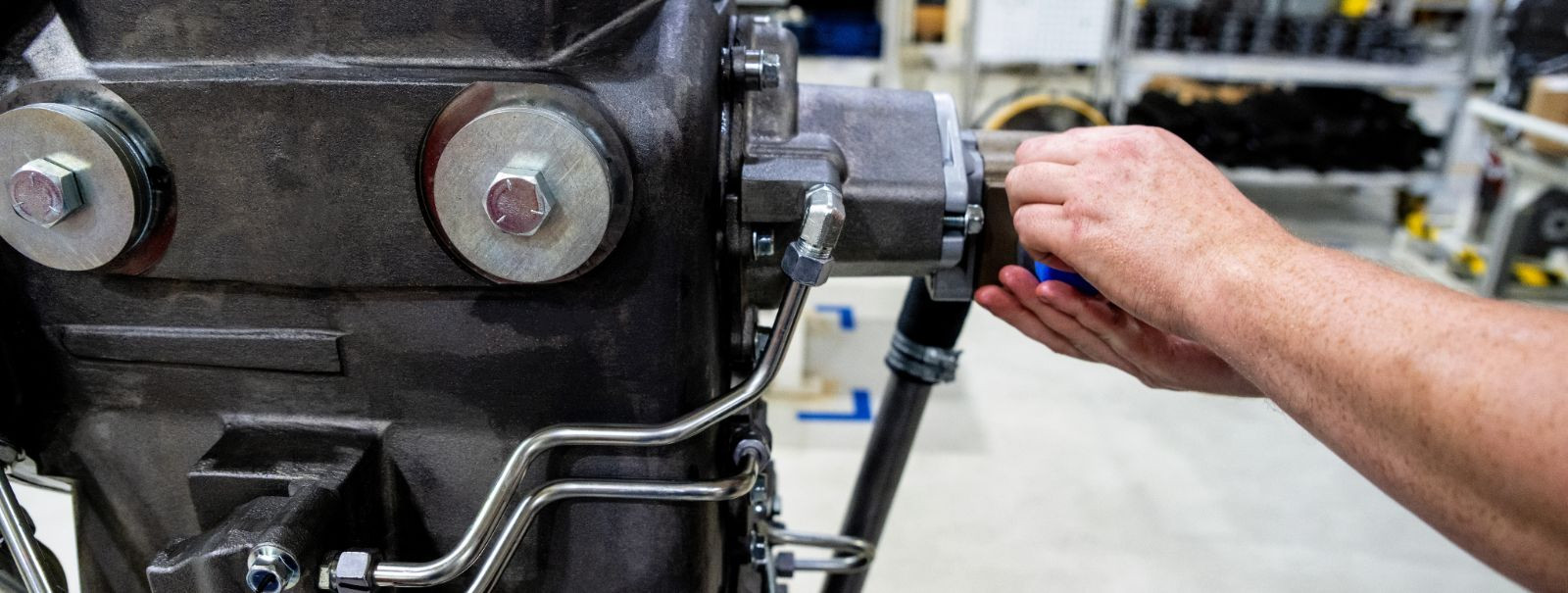

Hydraulic pumps are the heart of any hydraulic system, converting mechanical energy into hydraulic energy, which powers a vast array of industrial machinery. The reliability of these pumps is crucial for the smooth operation of businesses in construction, manufacturing, and logistics.

Hydraulic pumps are integral to the operation of heavy machinery, playing a pivotal role in systems that require precise control and power. They enable the movement of fluids under high pressure, which in turn, operates the machinery.

When a hydraulic pump fails, it can lead to machine downtime, lost productivity, and can be a significant financial burden. Therefore, recognizing the early signs of pump failure is essential for timely repair and maintenance.

Sign #1: Unusual Noise Levels

One of the first indicators of a failing hydraulic pump is the presence of unusual noises. These can range from knocking, whining, or screeching sounds, which are not typical during normal operations.

Abnormal noises can be symptomatic of cavitation, aeration, or bearing failures. Immediate inspection and diagnosis by professionals can prevent further damage.

Sign #2: Elevated Temperature and Overheating

Hydraulic pumps are designed to operate within a specific temperature range. Consistent operation above this range can indicate a problem.

Overheating can lead to reduced lubrication, seal degradation, and eventual pump failure. Monitoring temperature and seeking repair services at the first sign of overheating is critical.

Sign #3: Decreased Performance and Response Time

Diminished hydraulic performance may manifest as slower operation or a lack of force. This can severely impact productivity and the efficiency of operations.

A lag in system response time can be a clear indicator of pump deterioration. Timely repairs can restore system efficiency and prevent costly downtime.

Sign #4: Fluid Leaks and Contamination

Fluid leaks not only cause a mess but can also lead to reduced fluid levels and air entering the system, which can damage the pump and other components.

Contamination from external sources or internal wear can lead to abrasion and reduced efficiency. Regular fluid analysis and system checks are essential to maintain pump integrity.

Sign #5: Abnormal Vibrations

Vibrations in hydraulic pumps can be due to misalignment, worn out components, or improper mounting. These vibrations can accelerate wear and lead to premature failure.

Addressing abnormal vibrations promptly can prevent further damage. A thorough inspection by skilled technicians can identify the root cause and recommend the appropriate repairs.

Comments (0)