Maximizing productivity with regular equipment maintenance

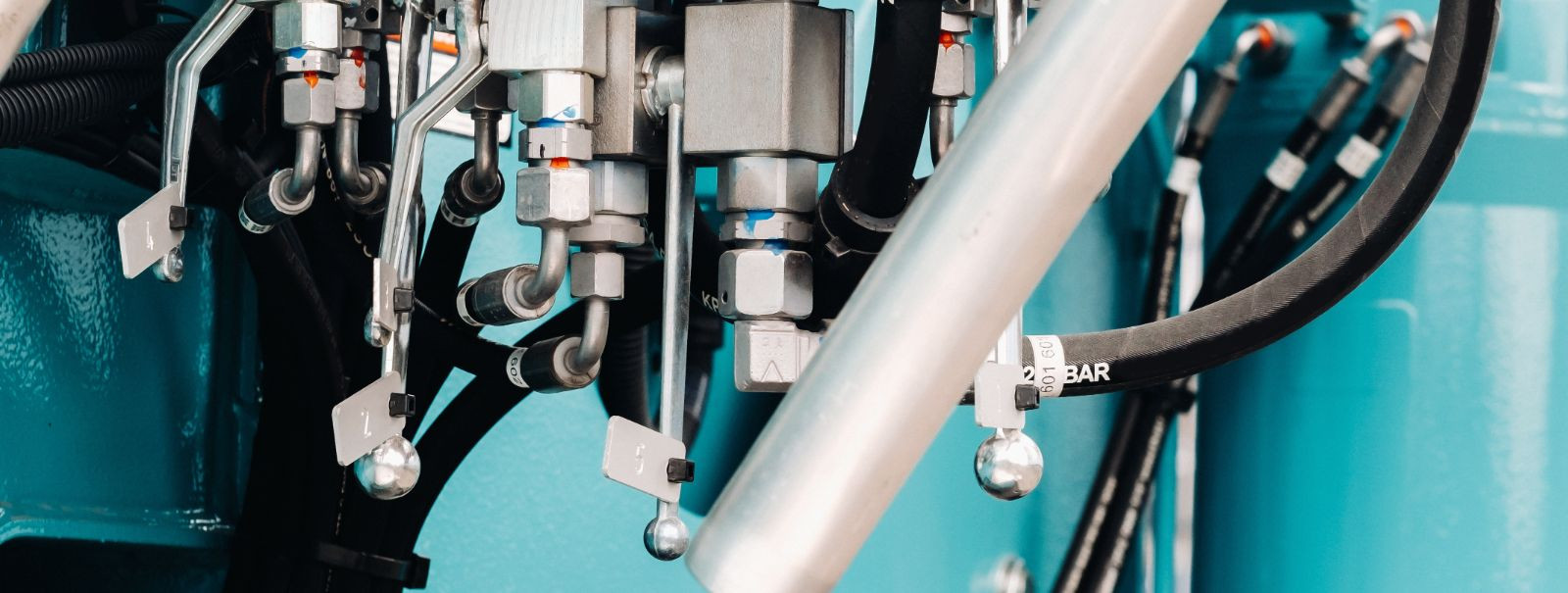

Maintaining industrial equipment is not just a matter of fixing what's broken; it's about preventing breakdowns before they occur. Regular maintenance is the key to ensuring that hydraulic and technological equipment operates at peak performance, which is crucial for industries such as construction, manufacturing, and logistics.

Downtime in any industrial sector can lead to significant financial losses. When equipment fails, projects get delayed, productivity drops, and the ripple effect on the supply chain can be catastrophic. Regular maintenance helps mitigate these risks by keeping equipment in optimal condition.

The Benefits of Regular Maintenance

Regular maintenance can significantly extend the life of your equipment. By addressing wear and tear proactively, you avoid the more severe damage that can result from neglect.

Well-maintained equipment is safer to operate. Regular checks can prevent accidents and ensure compliance with safety regulations, protecting your workforce and avoiding costly legal issues.

Equipment that is regularly serviced doesn't just last longer; it also performs better. Maintenance ensures that every component is functioning correctly, leading to improved efficiency and productivity.

Unexpected repairs can be expensive. Regular maintenance allows for better budgeting and cost predictability, as it's easier to forecast maintenance expenses than emergency repair costs.

Maintenance Strategies for Optimal Productivity

Preventive maintenance involves regularly scheduled inspections and servicing to prevent problems before they occur. This approach is essential for minimizing downtime and maintaining consistent productivity.

Predictive maintenance uses data and analytics to predict when equipment failure might occur, allowing for maintenance to be performed just in time to prevent a breakdown.

Proactive maintenance takes things a step further by modifying equipment and systems to improve performance and prevent future issues, often based on insights gained from predictive maintenance.

Implementing a Successful Maintenance Program

Every piece of equipment has unique maintenance requirements. A thorough assessment is crucial to developing an effective maintenance plan tailored to your equipment's specific needs.

For a maintenance program to be successful, your team must be properly trained and empowered to carry out maintenance tasks effectively. This includes understanding the importance of maintenance and being equipped with the right tools and knowledge.

Modern maintenance management systems can streamline the process, making it easier to schedule, track, and analyze maintenance activities. Technology can also facilitate predictive and proactive maintenance strategies.

Partnering with maintenance experts like SIKE OÜ can provide the specialized knowledge and services required to maintain complex hydraulic and technological equipment. Such partnerships can be invaluable for businesses that lack in-house expertise or need additional support.

Comments (0)