Eco-friendly cleaning: why laser technology is the answer

In today's world, sustainability is no longer a choice but a necessity. As industries evolve, the demand for eco-friendly cleaning solutions that do not compromise on efficiency or effectiveness has become paramount. The cleaning industry, in particular, has seen a significant shift towards green practices, driven by environmental concerns and regulatory pressures.

Traditional cleaning methods often involve the use of harsh chemicals, abrasive techniques, and substantial water consumption, leading to environmental degradation and health risks. In contrast, eco-friendly alternatives aim to minimize ecological footprints while maintaining high standards of cleanliness and hygiene.

Understanding Laser Cleaning Technology

Laser cleaning technology harnesses the power of light to remove contaminants from surfaces without the need for chemicals or abrasive materials. It operates by directing focused laser beams onto the surface, which absorbs the light energy and disintegrates or vaporizes the unwanted material, leaving the underlying surface intact.

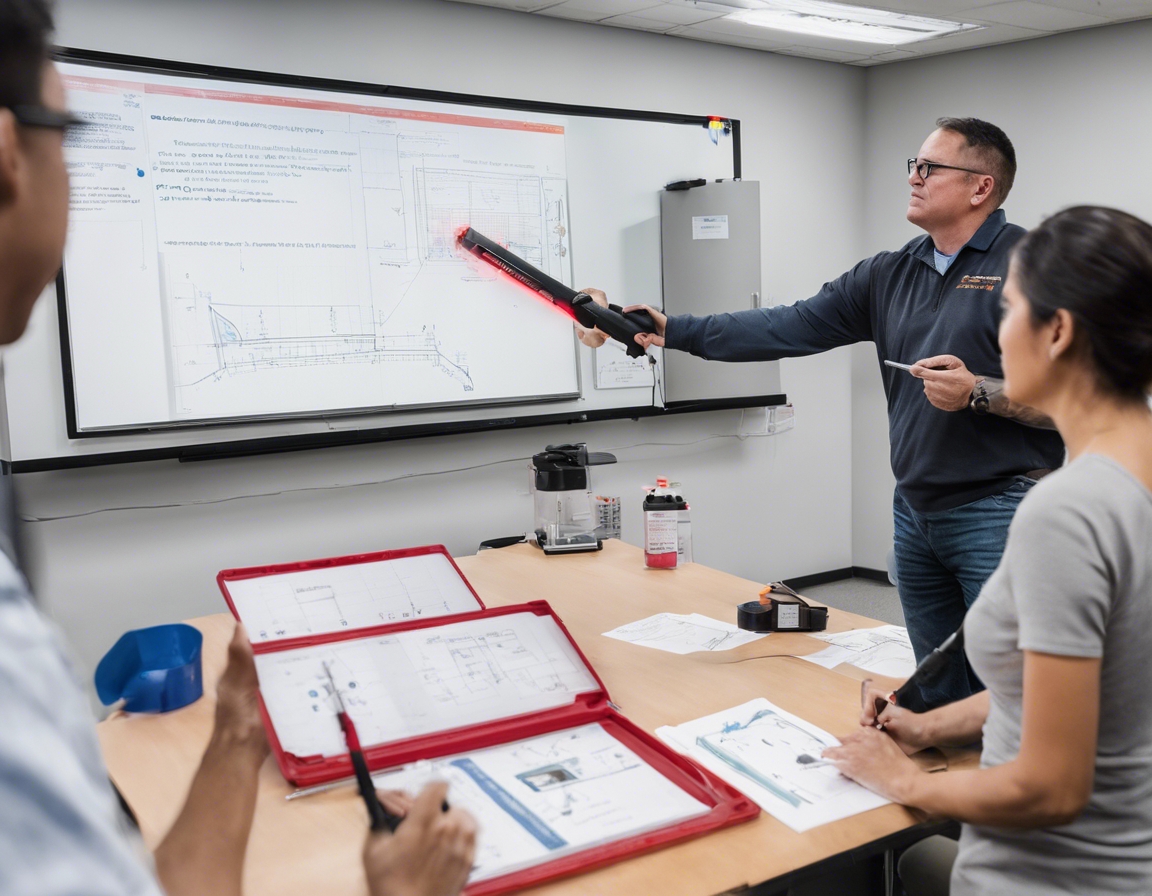

There are various types of laser cleaning systems designed to cater to different applications, ranging from handheld devices for spot cleaning to fully automated systems for large-scale operations. The choice of system depends on the specific requirements of the task at hand.

Benefits of Laser Cleaning

Laser cleaning stands out as an environmentally friendly option, as it eliminates the need for chemicals and reduces waste generation. It also conserves water, making it a sustainable choice for industries looking to reduce their environmental impact.

One of the key advantages of laser cleaning is its efficiency. The process is fast, precise, and can be controlled with great accuracy, which is essential for delicate or complex cleaning tasks. This precision also means less downtime for machinery and equipment, leading to increased productivity.

Unlike traditional methods that can pose health risks due to chemical exposure, laser cleaning is a safer alternative for operators. It reduces the risk of accidents and health issues, contributing to a safer workplace environment.

Laser Cleaning Applications

Laser cleaning is highly effective for maintaining industrial machinery and equipment. It can remove rust, paint, and other coatings without damaging the substrate, ensuring that machines operate at peak efficiency.

In the field of cultural heritage, laser cleaning is invaluable for restoring artifacts and monuments. It allows for the gentle removal of contaminants without harming the original materials, preserving historical integrity.

Manufacturers can benefit from laser cleaning by incorporating it into their production lines to clean parts and assemblies. This ensures high-quality finishes and proper adhesion of coatings or treatments.

Choosing the Right Laser Cleaning Solution

When selecting a laser cleaning system, factors such as the type of contaminant, the material of the substrate, and the scale of the cleaning task must be considered. It's important to choose a system that aligns with the specific needs of the application.

LASEREST OÜ is dedicated to providing cutting-edge laser cleaning solutions that meet the highest standards of sustainability and performance. With a range of systems designed for various applications, LASEREST OÜ is at the forefront of eco-friendly cleaning technology.

Comments (0)