The future of restoration: how laser technology is changing the game

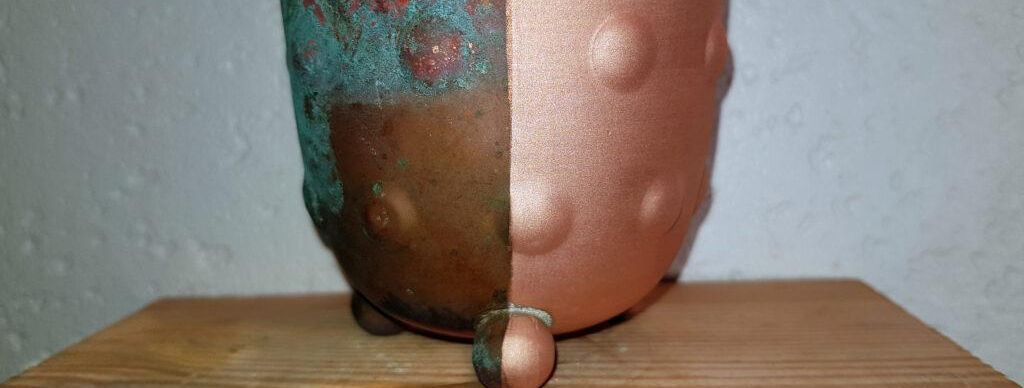

Laser cleaning technology, a process that utilizes laser energy to remove contaminants, coatings, or residues from various surfaces, is revolutionizing the restoration industry. This non-contact and non-abrasive method offers a high level of precision, making it ideal for delicate and detailed work.

Traditional restoration methods often involve chemical solvents, abrasive blasting, or manual scrubbing. These techniques, while effective, come with downsides such as potential damage to the substrate, environmental concerns, and health risks. The advent of laser technology in restoration has provided a groundbreaking alternative.

The Advantages of Laser Technology in Restoration

Laser cleaning systems offer unparalleled precision, allowing operators to target specific areas without affecting the surrounding material. This is particularly beneficial in the restoration of intricate machinery parts and historic artifacts.

One of the most compelling benefits of laser cleaning is its minimal environmental footprint. The process eliminates the need for harsh chemicals and reduces waste, aligning with the sustainability goals of many organizations.

Laser cleaning is not only precise but also incredibly efficient. It can significantly reduce cleaning times compared to traditional methods, leading to increased productivity and reduced downtime.

The reduction of hazardous chemicals and dust generation in the cleaning process is a significant health benefit. Laser technology enhances workplace safety and reduces the risk of health issues associated with conventional cleaning methods.

Laser Technology Applications in Restoration

Laser cleaning is ideal for maintaining industrial equipment, removing rust, paint, and other build-ups without damaging the underlying material.

In the field of cultural heritage, lasers are used to delicately remove contaminants from historic structures and artifacts, preserving their integrity for future generations.

Manufacturers benefit from laser technology by keeping their equipment in optimal condition, ensuring quality production and extending the lifespan of their machinery.

Technological Innovations in Laser Restoration

Continuous improvements in laser technology have led to more portable, powerful, and user-friendly systems, expanding the possibilities of restoration projects.

Integration of advanced software and automation has made laser cleaning more precise and efficient, allowing for complex cleaning patterns and reduced operator intervention.

Challenges and Considerations

While laser technology offers numerous benefits, the initial investment can be significant. However, the long-term savings in maintenance, labor, and materials often justify the upfront cost.

Effective laser cleaning requires skilled operators. As the technology becomes more widespread, the need for specialized training programs is growing.

Adhering to safety standards and regulations is crucial in the implementation of laser technology. Companies must ensure proper safety measures are in place to protect operators and the environment.

Comments (0)