The importance of zinc plating in modern manufacturing

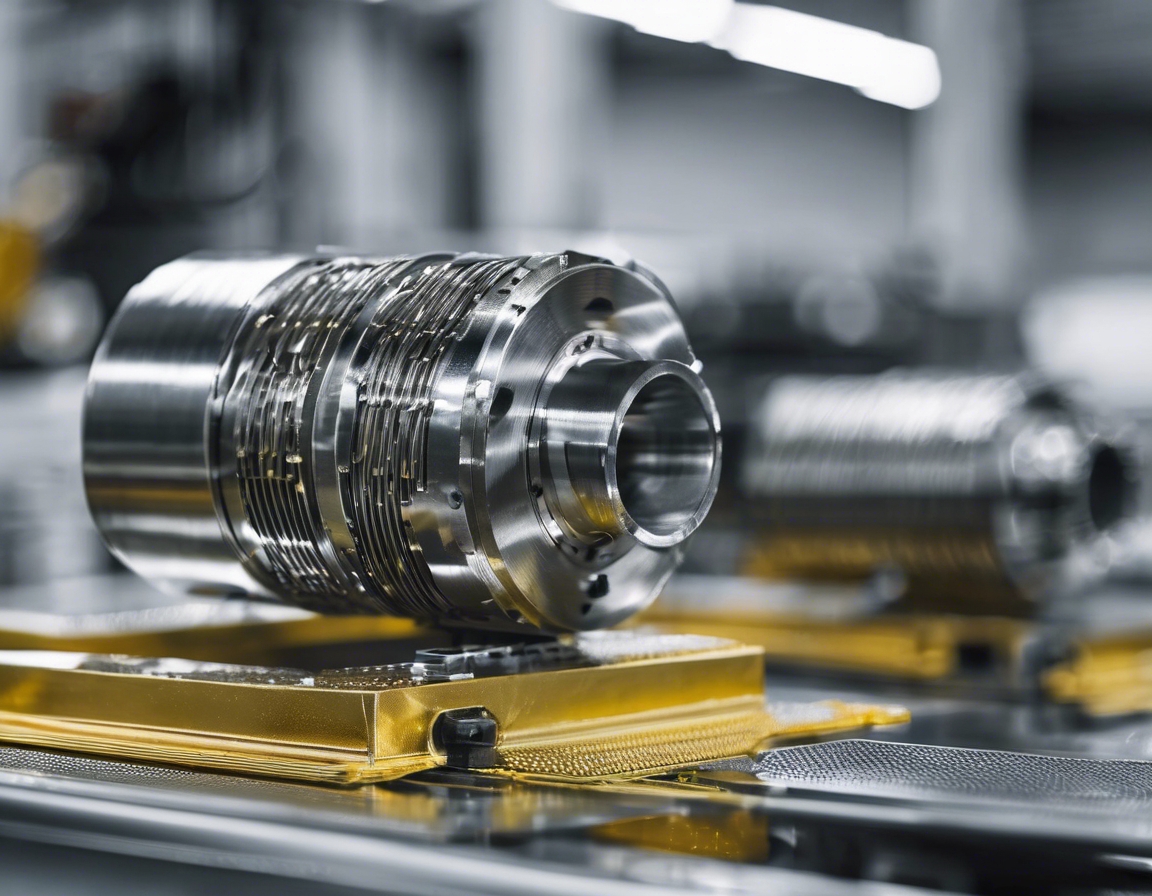

Zinc plating is a widely used process in modern manufacturing, providing a protective layer to metal surfaces to prevent corrosion and enhance durability. This technique involves applying a thin layer of zinc to the surface of metal components, offering both functional and aesthetic benefits. As industries continue to demand high-quality, long-lasting products, zinc plating has become an essential part of manufacturing processes across various sectors.

The Process of Zinc Plating

The zinc plating process begins with thorough cleaning and preparation of the metal surface. This step is crucial to ensure proper adhesion of the zinc layer. The metal parts are typically cleaned using alkaline solutions or acid baths to remove any dirt, grease, or oxide layers.

Once the surface is prepared, the electroplating process begins. The metal parts are submerged in a zinc electrolyte solution, and an electric current is applied. This causes zinc ions to deposit onto the metal surface, forming a uniform and protective coating.

After electroplating, the components undergo post-treatment processes such as passivation or chromate conversion coating. These treatments enhance the corrosion resistance and aesthetic appeal of the zinc-plated parts, ensuring they meet industry standards and customer expectations.

Benefits of Zinc Plating

One of the primary benefits of zinc plating is its ability to protect metal surfaces from corrosion. The zinc layer acts as a sacrificial anode, corroding in place of the underlying metal and significantly extending the lifespan of the components.

Zinc plating also improves the visual appeal of metal parts. The shiny, smooth finish provided by zinc plating enhances the overall appearance of products, making them more attractive to consumers and suitable for visible applications.

Compared to other protective coatings, zinc plating is a cost-effective solution. It provides excellent protection at a relatively low cost, making it an attractive option for manufacturers looking to balance quality and budget.

Modern zinc plating processes have evolved to become more environmentally friendly. With advancements in technology, the use of hazardous chemicals has been minimized, and waste management practices have improved, aligning with global sustainability goals.

Applications of Zinc Plating in Various Industries

In the automotive industry, zinc plating is used extensively to protect components such as bolts, nuts, and brackets from corrosion. This ensures the longevity and reliability of vehicles, even in harsh environmental conditions.

The construction sector benefits from zinc plating through the protection of structural components, fasteners, and fittings. This enhances the durability of buildings and infrastructure, reducing maintenance costs and extending service life.

In the electronics industry, zinc plating is used to protect connectors, terminals, and other components from corrosion and wear. This ensures the reliability and performance of electronic devices over time.

Challenges and Considerations in Zinc Plating

When considering zinc plating, it is essential to ensure compatibility with the base material. Some metals may require specific pre-treatment processes to achieve optimal adhesion and performance.

Achieving the correct thickness and uniformity of the zinc coating is crucial for effective protection. Manufacturers must carefully control the plating process to ensure consistent results across all components.

Compliance with environmental regulations is a critical consideration in zinc plating. Manufacturers must adhere to local and international standards to minimize environmental impact and ensure sustainable practices.

Comments (0)