VG HOLDING AS current status

This company's branding has already reached 23,210 peopleand his is followed by 41 Storybook users.On average, the company has been rated 4.7 points.and commented 2 times.

Tegevusaruanne 2024

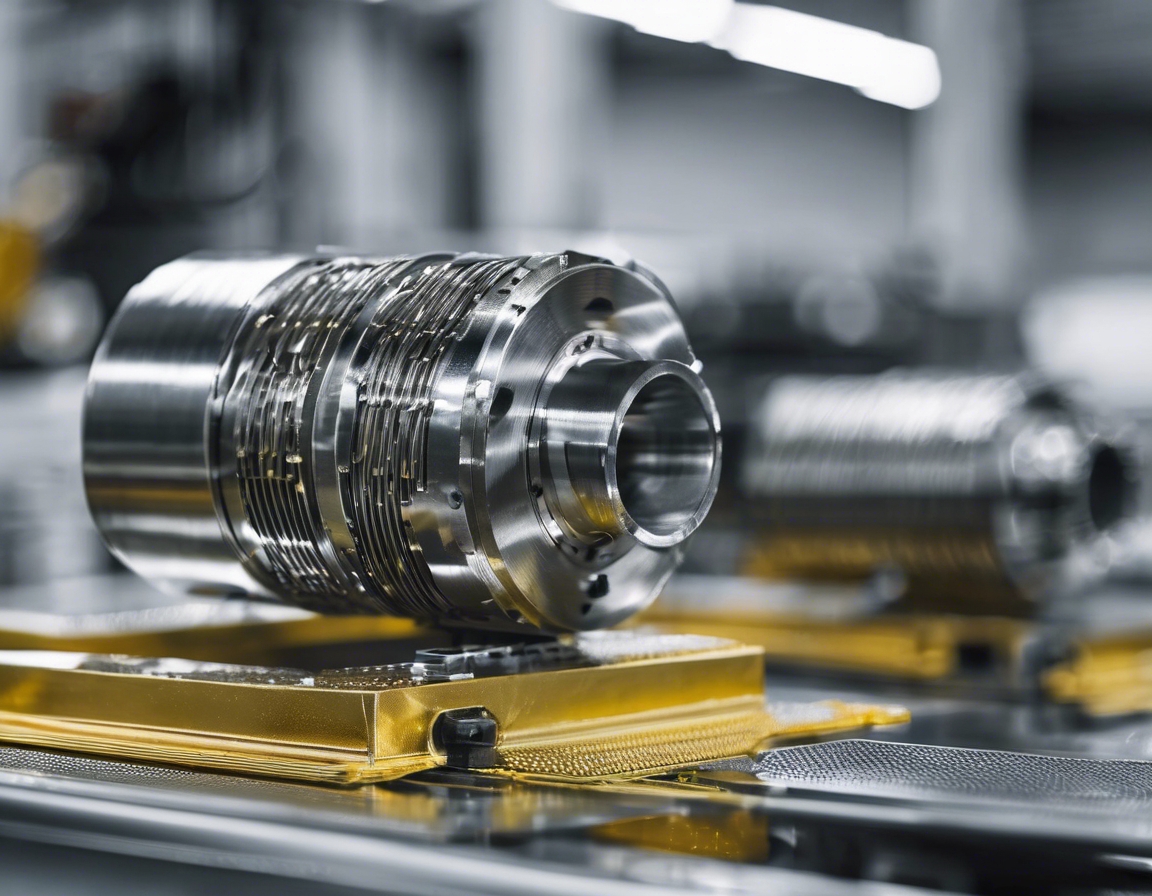

VG Holding AS põhitegevuseks on metallpindade galvaaniline katmine. Müügitulu 2024 aastal oli 318 864 eurot.Võrreldes 2023 aastaga müügitulu langes 9,64 % võrra.

Ülevaate ettevõtte majandustegevusesest saame finantssuhtarvude abil tehtud analüüsist.

Peamised finantssuhtarvud olid: 2024 2023

Müügitulu 318 864 352 886

Puhaskasumimarginaal 0,33 % 7 %

Ärikasumimarginaal 2 % 8 %

Omakapitali määr 0,61 % 0,58 %

Lühiajaliste kohustuste 0,53 0,45 katterordaja

ROA 0,25 6

ROE 0,42 9

Tulu kasv -9,64 % -16 %

Keskmine vara 416 877 458 653

Keskmine omakapital 249 685 279 251

Puhaskasum 1 058 27 310

Lühiajalised kohustused 134 763 157 328

Suhtarvude arvutamise valemid:

Puhaskasumimarginaal:puhaskasum/müügitulu*100

Tulu kasv(%)=(müügitulu 2024 – müügitulu 2023)/müügitulu 2023*100

Lühiajaliste kohustuste kattekordaja=käibevara/lühiajalised kohustused

Omakapitali määr=Aktsionäridele kuuluv omakapital/Varad kokku

Keskmine vara=(varad kokku 2024+varad kokku 2023)/2

ROA(vara puhas kasumi tootlus )=(puhaskasum/keskmine vara)*100

ROE(omakapitali puhas kasumi tootlus)=(puhaskasum/keskmine omakapital)*100

Peamiseks tegevusalaks on metallpindade tsinkimine,anodeerimine ja elektropoleerimine.

Ettevõtte juhatus koosneb kahest liikmest.

Tegevdirektori töötasu oli 11 927 eurot.

Aruandeaasta keskmine töötajate arv oli 9 töötajad.Töötajatele makstud töötasude üldsumma aruandeaastal oli 109 258 eurot.

Igor Gorškov

Comments (0)