The future of car demolition: eco-friendly practices

As the world becomes increasingly aware of the environmental impact of traditional industries, the automotive sector is no exception. Car demolition, a critical end-of-life phase for vehicles, is undergoing a transformation to adopt more sustainable practices. This shift not only benefits the environment but also offers economic advantages and aligns with global sustainability goals.

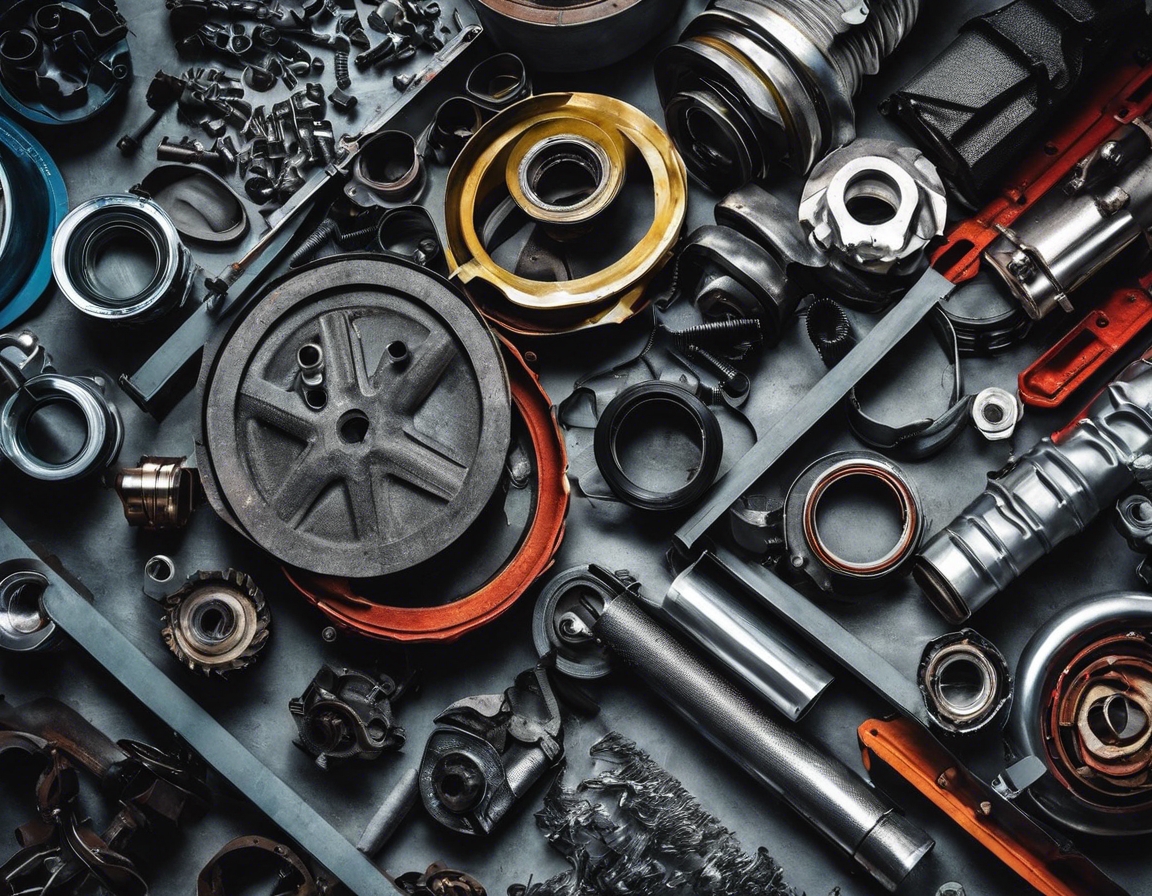

Currently, car demolition involves a mix of manual and mechanical processes to dismantle vehicles. While this method has been effective, it often results in significant waste and environmental harm due to improper disposal of hazardous materials and low recycling rates.

The automotive industry is under pressure to reduce its carbon footprint and waste. Eco-friendly car demolition practices are essential to minimize pollution, conserve resources, and create a circular economy where materials are reused and recycled.

Emerging Trends in Sustainable Car Demolition

Innovative dismantling techniques are being developed to increase efficiency and reduce waste. These include precision cutting tools and robotics that can disassemble vehicles more quickly and safely.

Reusing and recycling auto parts not only conserves resources but also provides affordable options for car owners and repair shops. High-quality parts can be refurbished and sold, reducing the need for new parts production.

Proper fluid recovery is crucial to prevent environmental contamination. Advanced systems are now in place to ensure that fluids such as oil, coolant, and fuel are safely extracted and either reused or disposed of responsibly.

Car manufacturers are increasingly using non-toxic materials in vehicle production, which makes the demolition process safer and more environmentally friendly. This shift also facilitates easier recycling and reduces health risks to workers.

Technological Innovations Driving Change

Automation in recycling processes has led to more efficient sorting and processing of materials, reducing labor costs and increasing the volume of materials that can be recycled.

Technologies such as infrared sensors and AI-driven systems can accurately identify and sort different materials, ensuring that more components are recycled correctly.

The use of energy-efficient machinery in car demolition reduces the overall carbon footprint of the process and lowers operational costs.

Regulatory Framework and Industry Standards

International regulations are pushing the automotive industry towards more sustainable practices. These regulations mandate certain recycling rates and proper disposal of hazardous materials.

Industry certifications such as ISO standards for environmental management systems are becoming more common, ensuring that car demolition practices meet high environmental performance criteria.

Challenges and Opportunities

Despite the clear benefits, transitioning to eco-friendly car demolition faces challenges such as high initial investments, the need for skilled labor, and changing consumer perceptions.

The move towards sustainable car demolition opens up new business opportunities for companies that can offer eco-friendly services. Consumers also benefit from access to affordable, quality parts and the knowledge that they are contributing to a greener planet.

Comments (0)