Thermal engraving: the new frontier in design

Thermal engraving, a cutting-edge technique in the world of design and construction, is a process that involves the use of controlled heat to etch designs onto various materials. This innovative method offers precision and versatility, allowing for intricate patterns and textures to be created on surfaces that were once considered difficult to manipulate.

While engraving itself has a rich history dating back to ancient times, thermal engraving is a modern iteration that harnesses the power of technology. The evolution from manual engraving to thermal techniques represents a significant leap forward, providing designers and builders with new possibilities for customization and creativity.

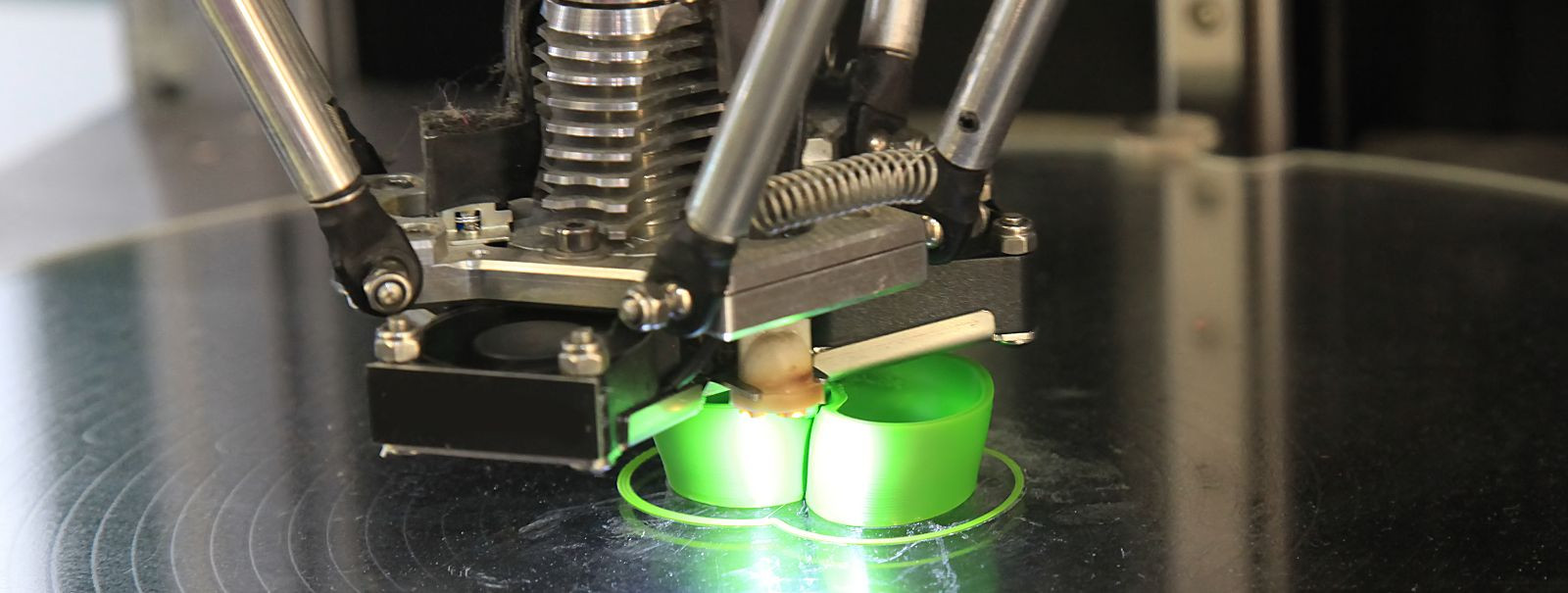

The Process of Thermal Engraving

Thermal engraving can be applied to a wide range of materials, including metals, plastics, glass, and even certain types of stone. The versatility of this method makes it an attractive option for various applications in the construction industry.

The thermal engraving process begins with the creation of a digital design, which is then translated into a physical pattern using specialized equipment. Heat is applied in a controlled manner to alter the surface of the material, resulting in a permanent and detailed engraving.

Applications of Thermal Engraving in Construction and Design

One of the most striking applications of thermal engraving is in the customization of building facades. This technique allows for unique patterns and branding elements to be incorporated into the exterior of buildings, setting them apart in the urban landscape.

Inside buildings, thermal engraving can be used to add bespoke touches to walls, flooring, and fixtures. The ability to create custom designs adds a level of sophistication and personalization to any interior space.

In the realm of landscaping, thermal engraving can be utilized to create durable and visually appealing outdoor features such as engraved pavers, signage, and decorative walls.

Benefits of Thermal Engraving for the Construction Industry

Engravings made through the thermal process are known for their durability, resisting wear and tear over time. This makes them ideal for high-traffic areas and external applications exposed to the elements.

Thermal engraving is a sustainable option, as it often requires less material and produces fewer waste products compared to traditional methods. This aligns with the growing demand for eco-friendly construction practices.

Despite its high-end appearance, thermal engraving can be a cost-effective solution due to its efficiency and the reduced need for manual labor. This can lead to significant savings for construction projects without compromising on quality.

Technological Advancements in Thermal Engraving

The continuous development of thermal engraving equipment and techniques has led to increased precision and faster production times. Modern machines are capable of handling complex designs with ease, further expanding the potential of this technology.

The integration of thermal engraving with digital design tools has streamlined the design-to-production workflow. Designers can now see their visions come to life with greater accuracy and in less time than ever before.

As the industry looks forward, we can expect to see further advancements in thermal engraving technology, including the use of AI and machine learning to push the boundaries of what can be achieved in design and construction.

Comments (0)