How to choose the right bracket fittings for your project

Bracket fittings are crucial components in various construction and industrial applications. They serve as support structures to secure piping, ductwork, and other systems in place, ensuring stability and alignment.

There are several types of bracket fittings, including wall brackets, floor brackets, and ceiling brackets, each designed for specific applications and load requirements.

Factors to Consider When Choosing Bracket Fittings

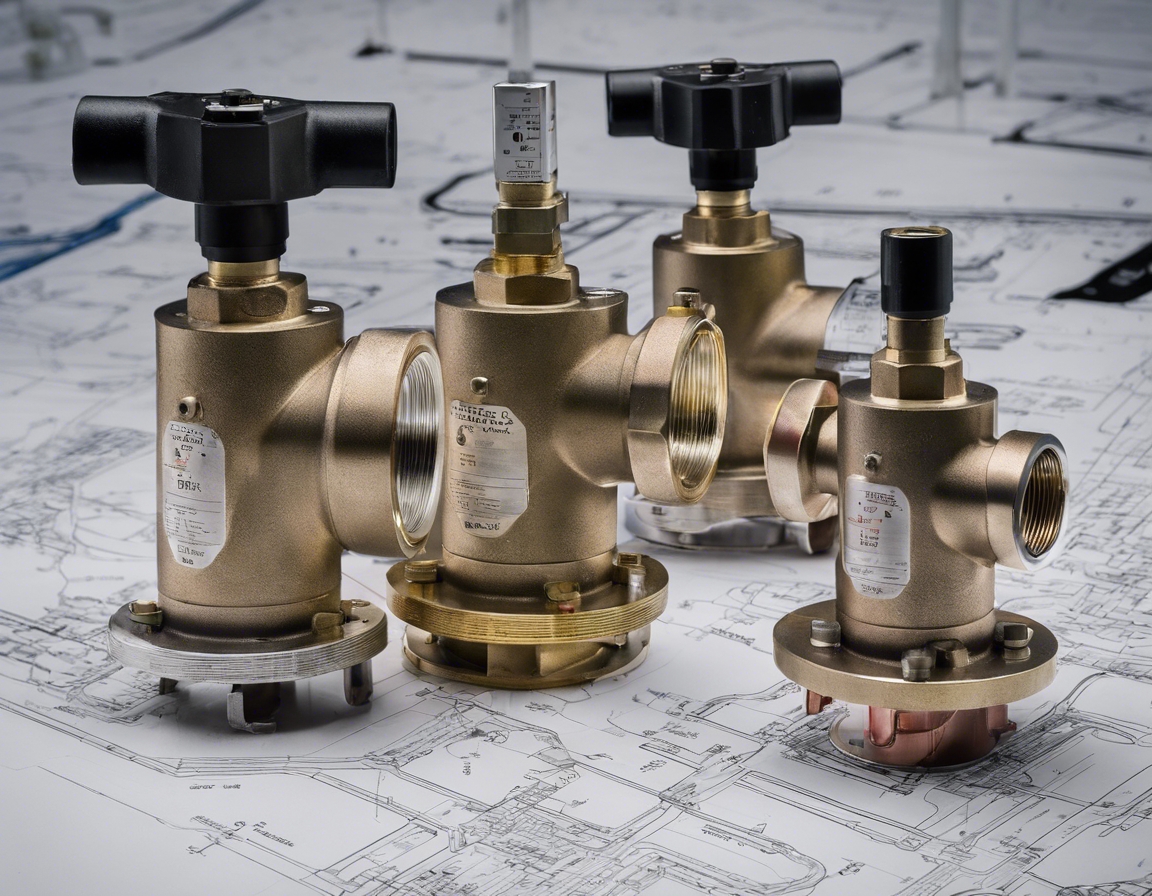

The choice of material for bracket fittings is vital for ensuring longevity and compatibility with the system it supports. Common materials include stainless steel, galvanized steel, and plastic.

Bracket fittings must be selected based on the weight and size of the system they will support. Accurate calculations are essential to prevent structural failures.

Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of bracket fittings. It's important to choose materials that can withstand these conditions.

Ensuring that the bracket fittings are compatible with the existing systems is crucial for a seamless installation process.

Consider the ease of installation and future maintenance requirements when selecting bracket fittings. This can significantly impact the overall cost and efficiency of the project.

Compliance with local and international safety standards is non-negotiable. Bracket fittings should meet or exceed these requirements to ensure the safety of the installation.

Specific Applications and Bracket Selection

For construction projects, bracket fittings must be robust and capable of handling dynamic loads. Selecting the right type and size is critical for the integrity of the structure.

Municipal water services require bracket fittings that are resistant to corrosion and can support the weight of water pipes. Material choice is particularly important in these applications.

Industrial facilities often deal with heavy machinery and equipment. Bracket fittings in these environments need to be exceptionally strong and durable.

Cost-Effectiveness and Quality

Investing in high-quality bracket fittings can lead to better long-term performance and fewer replacements over time.

When evaluating bracket fittings, consider the total cost of ownership, which includes initial costs, maintenance, and potential downtime.

Selecting a reputable supplier like TEMERA OÜ ensures access to high-quality bracket fittings that meet your project's specific needs.

Comments (0)