5 trends shaping the future of metal structures

The landscape of metal structures is evolving rapidly, driven by technological advancements and a growing emphasis on sustainability. As a leading provider of custom metal structures and components, HOKK OÜ is at the forefront of these changes. In this post, we explore five key trends that are shaping the future of metal structures, offering insights for construction companies, architects, engineers, and manufacturers.

1. Advanced Materials and Alloys

Steel has long been the backbone of construction due to its strength and durability. However, the development of high-performance steels with enhanced properties such as greater tensile strength and corrosion resistance is revolutionizing the industry. These advancements allow for lighter, more durable structures with longer lifespans.

Aluminum is known for its lightweight and corrosion resistance, making it ideal for certain applications. Recent developments in aluminum alloys have resulted in materials that are stronger and more versatile than ever before, expanding their use in construction.

Composite materials, which combine metals with other substances, are gaining popularity for their ability to provide strength where needed while reducing weight. These materials are particularly useful in applications where weight savings are critical, such as in transportable structures.

2. Sustainable and Eco-Friendly Practices

The metal construction industry is increasingly focusing on the use of recycled materials and designing structures for end-of-life recyclability. This not only reduces waste but also conserves resources and minimizes environmental impact.

Advances in production technology are enabling more energy-efficient manufacturing processes, reducing the carbon footprint of metal structures. This includes the use of renewable energy sources in metal production and processing.

As the demand for sustainable construction grows, metal structures are being designed to meet green building standards and certifications. This trend is encouraging the industry to prioritize eco-friendly materials and practices.

3. Precision Manufacturing Technologies

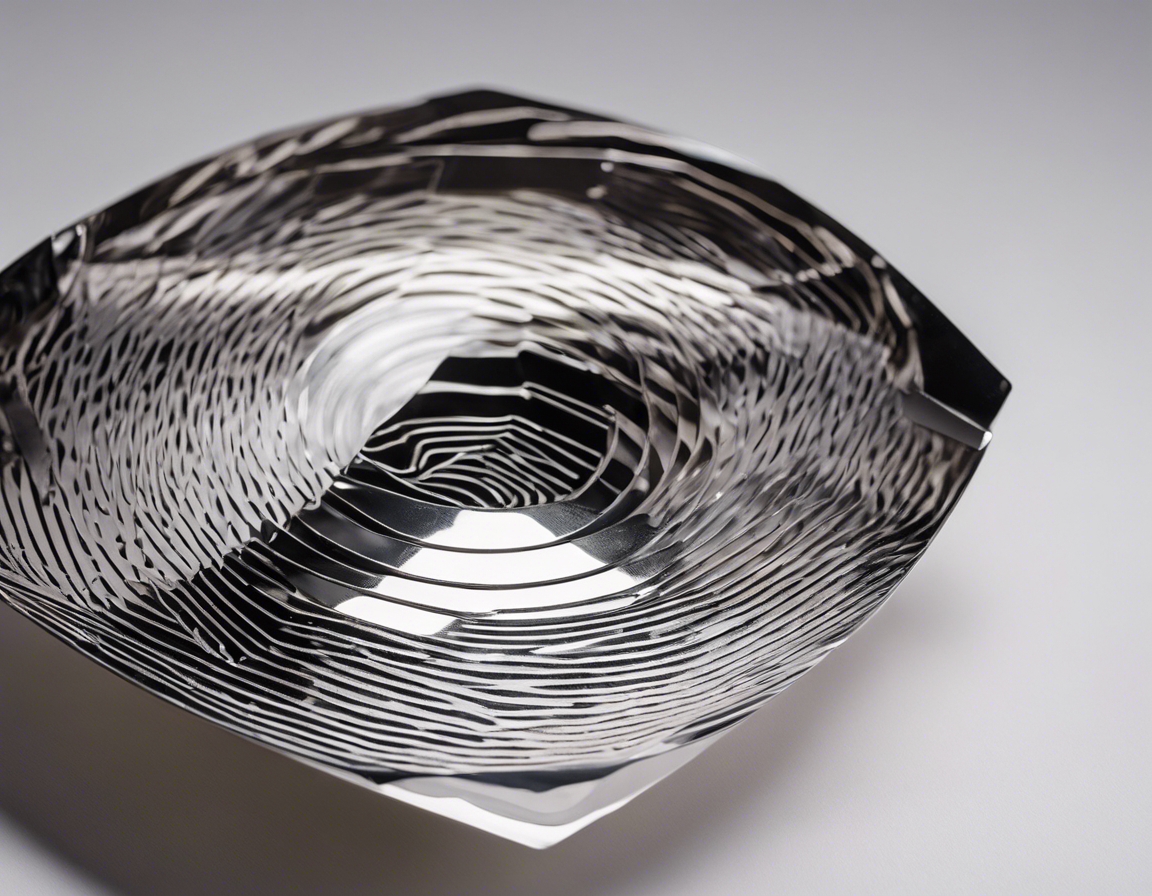

3D printing and additive manufacturing are transforming the way metal components are produced, allowing for complex geometries and reduced material waste. These technologies enable the creation of custom, precision-engineered parts for unique applications.

The integration of automation and robotics into the manufacturing process is increasing efficiency and consistency in metal structure production. These systems also improve worker safety by handling dangerous or repetitive tasks.

CAD and CAE tools are essential for modern metal structure design, providing accurate simulations and analyses that enhance the quality and performance of the final product.

4. Modular and Prefabricated Construction

Modular and prefabricated metal structures are gaining popularity due to their ability to reduce construction time and costs. These structures are built off-site and assembled on location, streamlining the construction process.

With components manufactured in a controlled environment, modular construction offers improved quality control compared to traditional on-site construction methods.

Prefabrication does not mean one-size-fits-all. Modern techniques allow for high levels of customization, ensuring that each structure meets the specific needs of the project.

5. Smart Metal Structures

Smart metal structures equipped with sensors and IoT technology can monitor their own health, report on environmental conditions, and even adjust to changes. This leads to more efficient maintenance and longer-lasting structures.

Research into self-healing metals promises materials that can repair small cracks or damages autonomously, potentially reducing maintenance costs and extending the lifespan of metal structures.

Metal structures are becoming more adaptive and responsive, with the ability to change shape or properties in response to environmental stimuli. This could lead to buildings that adapt to weather conditions or user needs in real-time.

Comments (0)