What is the importance of technical design in manufacturing?

Technical design is the backbone of manufacturing, serving as the blueprint for creating products that meet specific requirements and standards. It encompasses the detailed planning and specification of every aspect of a product, from its dimensions and materials to its functionality and life cycle considerations.

Technical design refers to the process of devising and detailing the engineering specifications of a product. It involves a comprehensive understanding of engineering principles, materials science, and the intended use of the product.

Technical design is critical in manufacturing as it directly influences the feasibility, quality, and cost-effectiveness of the production process. It is the stage where potential issues are identified and resolved before production, ensuring a smooth transition from concept to market.

Key Components of Effective Technical Design

Precision in technical design is non-negotiable. Accurate specifications ensure that each component fits perfectly, reducing the need for adjustments during assembly and enhancing the overall quality of the final product.

Choosing the right materials is essential for the functionality and sustainability of the product. Technical designers must consider factors such as strength, durability, and environmental impact.

Design for Manufacturability (DFM) is a proactive approach to designing products that are easy to manufacture. It simplifies the production process, minimizes errors, and reduces costs.

Adhering to industry standards and regulatory compliance is a critical aspect of technical design. It ensures that products are safe, reliable, and acceptable in their target markets.

Technical Design and Its Impact on Manufacturing Outcomes

High-quality technical design translates into superior products. It lays the groundwork for manufacturing excellence, leading to products that surpass customer expectations.

Efficient technical design streamlines the production process, enabling faster turnaround times from design to delivery, which is crucial in today's competitive market.

By optimizing the design for cost-effective manufacturing, companies can reduce waste, lower production costs, and increase profitability.

Technical design is at the forefront of innovation, allowing manufacturers to integrate new technologies and materials into their products, thereby staying ahead of the curve.

Challenges in Technical Design for Manufacturing

The increasing complexity of products requires sophisticated technical design capabilities to ensure all components work harmoniously together.

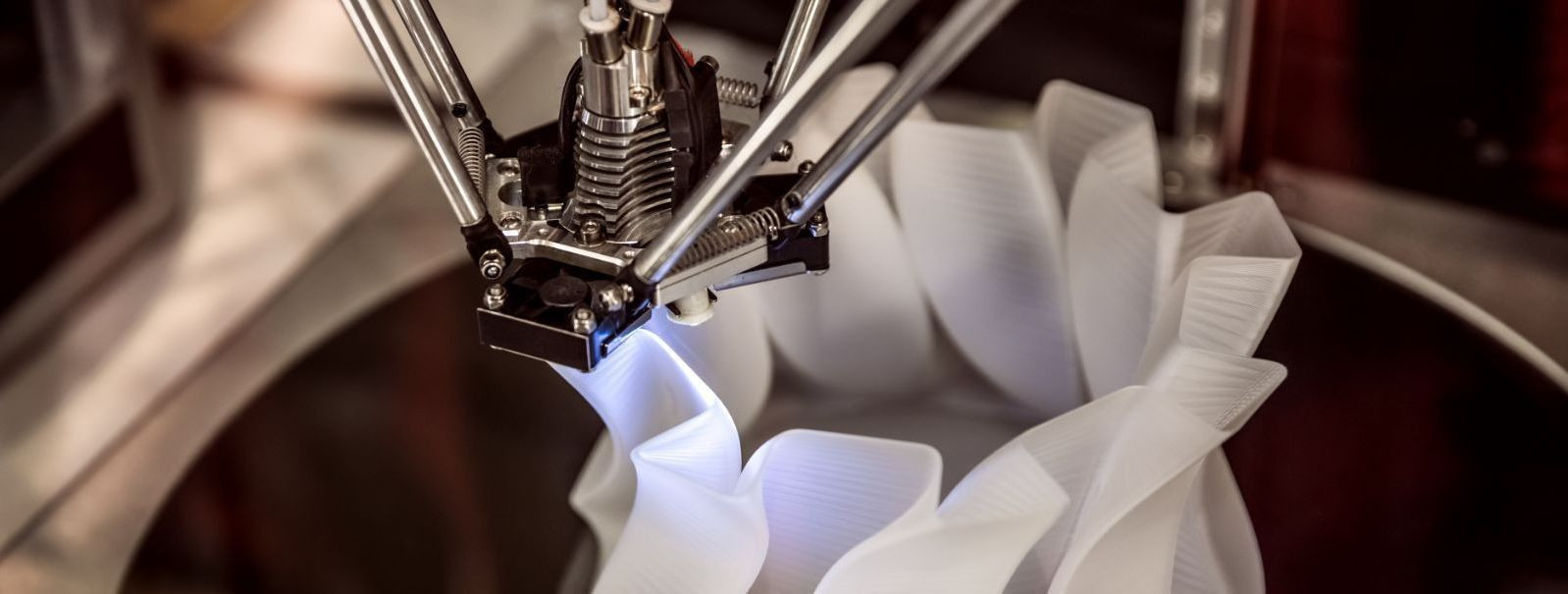

Embracing new technologies such as 3D printing and IoT demands a reevaluation of traditional technical design practices to maintain a competitive edge.

Global supply chains introduce variables that must be accounted for in technical design, including logistics, cultural differences, and international standards.

How BALTIC IDEA SOLUTIONS OÜ Addresses Technical Design Needs

BALTIC IDEA SOLUTIONS OÜ boasts a team of experts with the specialized knowledge required to tackle complex technical design challenges in manufacturing.

We provide tailored technical design solutions that align with our clients' unique manufacturing goals and requirements.

Our commitment to quality and efficiency ensures that we deliver technical designs that not only meet but exceed industry standards.

Seeking unparalleled technical design expertise for your manufacturing projects? Contact BALTIC IDEA SOLUTIONS OÜ to ensure precision, innovation, and efficiency.

Contact

Comments (0)