Sustainability in conveyor system design: a growing trend

In recent years, the industrial sector has witnessed a significant shift towards sustainability, with conveyor system design being no exception. As industries strive to reduce their carbon footprint and enhance operational efficiency, sustainable conveyor systems have emerged as a crucial component in achieving these goals. This growing trend is not only driven by environmental concerns but also by the economic and operational benefits that sustainable practices offer.

The Importance of Sustainable Conveyor Systems

Conveyor systems are integral to various industries, including mining, waste management, and logistics. However, traditional conveyor systems can contribute significantly to environmental degradation through energy consumption and material waste. Sustainable conveyor systems aim to minimize these impacts by incorporating eco-friendly materials and energy-efficient technologies, thereby reducing greenhouse gas emissions and conserving natural resources.

Beyond environmental advantages, sustainable conveyor systems offer substantial economic benefits. By optimizing energy use and reducing waste, businesses can achieve significant cost savings. Additionally, sustainable systems often require less maintenance and have longer lifespans, further reducing operational costs and enhancing profitability.

Key Elements of Sustainable Conveyor Design

Energy efficiency is a cornerstone of sustainable conveyor design. Modern systems are equipped with energy-efficient motors and variable frequency drives that adjust the conveyor's speed based on load requirements, thereby minimizing energy consumption. Implementing energy-efficient practices not only reduces operational costs but also aligns with global sustainability goals.

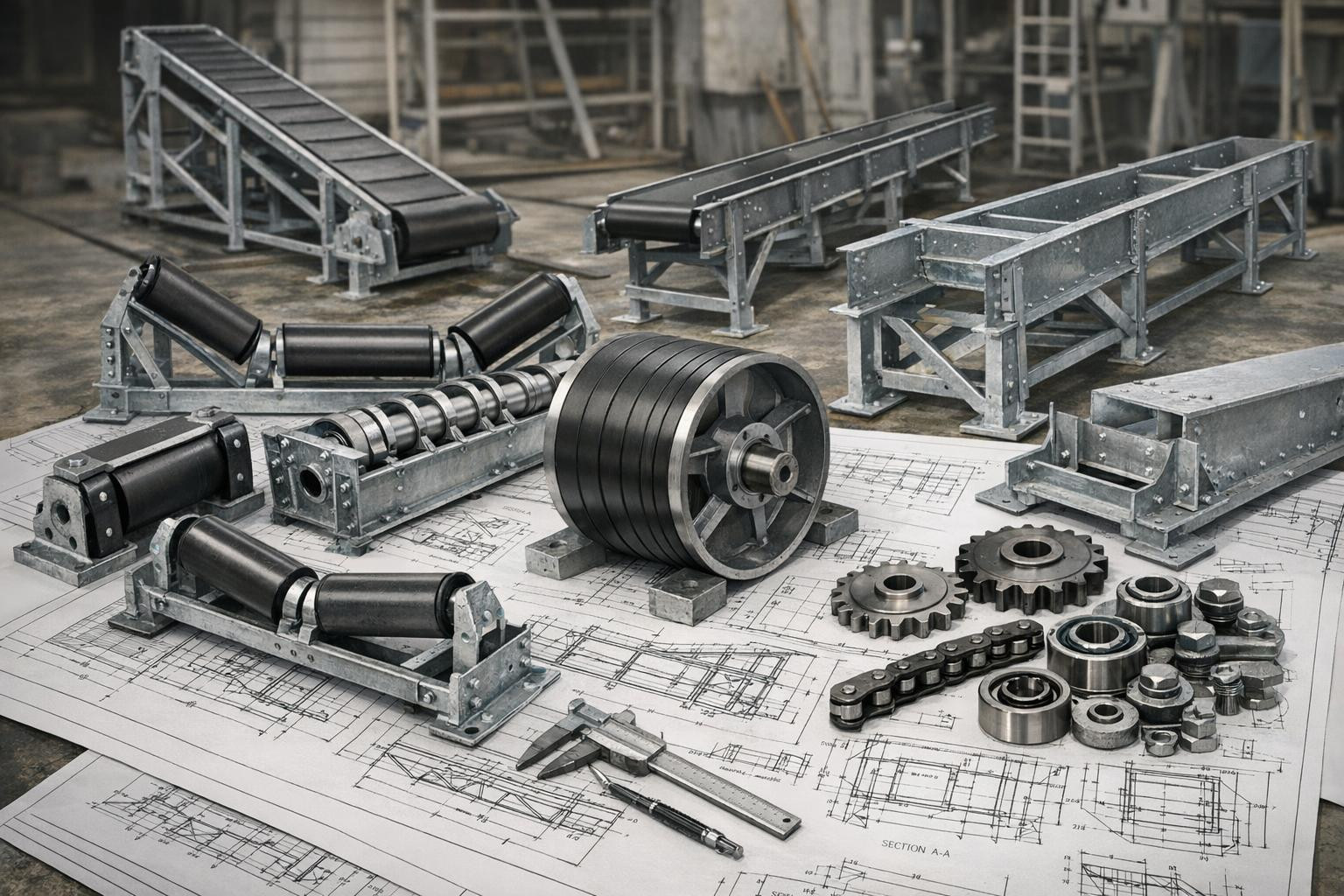

The choice of materials plays a critical role in the sustainability of conveyor systems. Utilizing recycled and recyclable materials reduces the environmental impact and supports a circular economy. Additionally, selecting durable materials that withstand wear and tear extends the system's lifespan, reducing the need for frequent replacements.

Designing conveyor systems with longevity in mind is essential for sustainability. Systems that are easy to maintain and repair not only reduce downtime but also extend the operational life of the equipment. Implementing predictive maintenance technologies can further enhance system reliability and efficiency.

Innovations Driving Sustainability in Conveyor Systems

Smart technologies, such as IoT sensors and automation, are revolutionizing conveyor system design. These technologies enable real-time monitoring and data analysis, allowing for proactive maintenance and optimization of system performance. By reducing energy consumption and improving efficiency, smart technologies contribute significantly to sustainability efforts.

Modular conveyor systems offer flexibility and scalability, making them ideal for sustainable design. These systems can be easily reconfigured or expanded to meet changing operational needs, reducing the need for new installations and minimizing waste. Modular designs also facilitate easier maintenance and upgrades, further enhancing sustainability.

Incorporating renewable energy sources, such as solar or wind power, into conveyor system operations is a growing trend. By harnessing clean energy, businesses can reduce their reliance on fossil fuels and decrease their carbon footprint. This approach not only supports environmental sustainability but also provides long-term energy cost savings.

Challenges and Considerations in Implementing Sustainable Conveyor Systems

One of the primary challenges in adopting sustainable conveyor systems is the initial investment cost. While sustainable systems may require higher upfront expenses, the long-term savings in energy and maintenance costs often justify the investment. Businesses must carefully evaluate the cost-benefit ratio to make informed decisions.

Integrating new technologies into existing conveyor systems can be challenging. Businesses must ensure that their workforce is adequately trained to operate and maintain advanced systems. Additionally, compatibility with existing infrastructure must be considered to avoid disruptions in operations.

As sustainability becomes a global priority, regulatory requirements are becoming more stringent. Businesses must stay informed about relevant regulations and ensure that their conveyor systems comply with environmental standards. Compliance not only avoids legal issues but also enhances the company's reputation as a responsible and sustainable entity.

Comments (0)