The future of conveyor systems in industrial automation

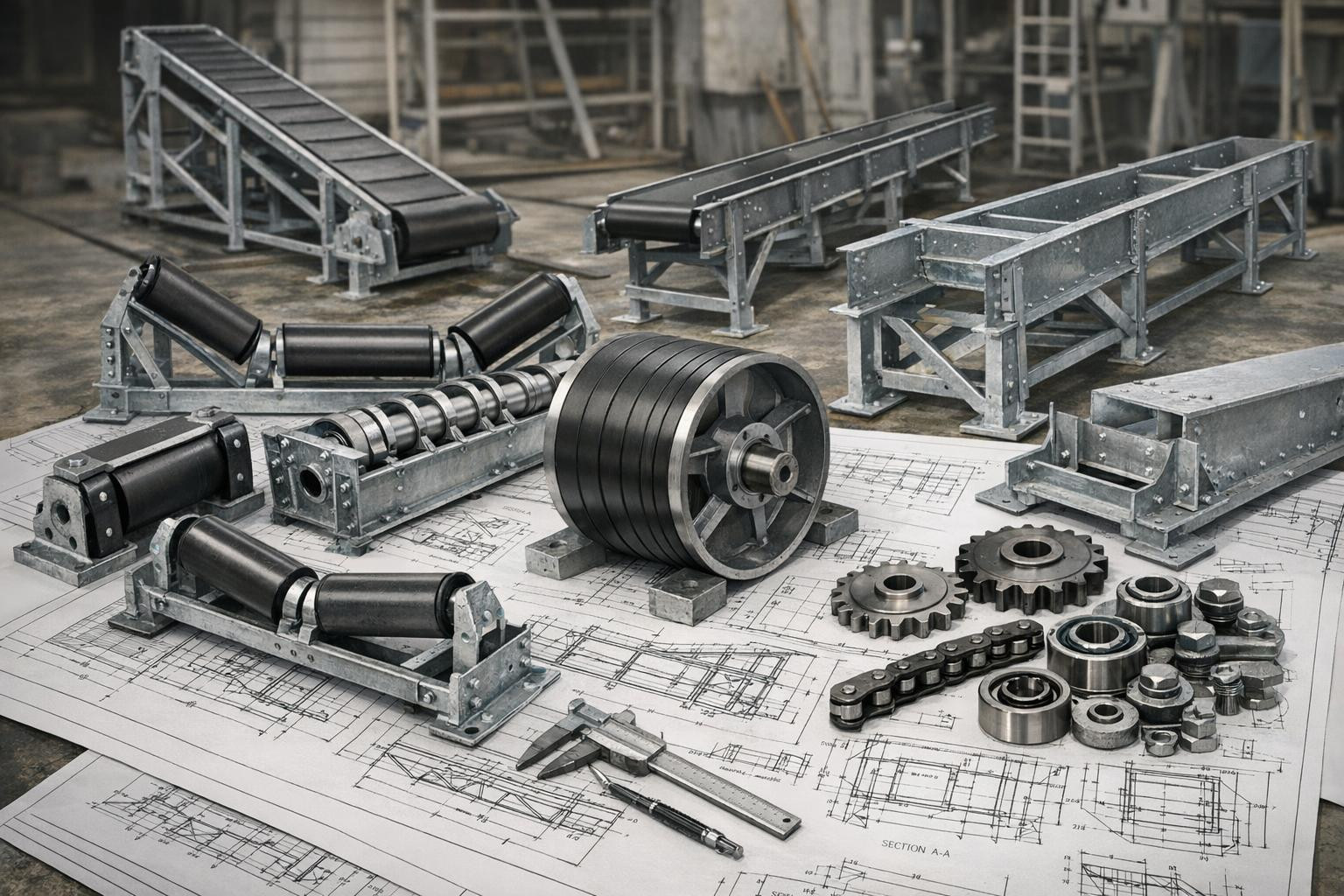

Conveyor systems have long been the backbone of industrial automation, providing a reliable and efficient means of transporting materials across various sectors. As industries continue to evolve, the demand for more advanced and integrated conveyor solutions is on the rise. This blog explores the future of conveyor systems, focusing on technological advancements, industry-specific applications, and the innovations driving this transformation.

2. Current Trends in Conveyor Systems

Technological advancements are reshaping the landscape of conveyor systems. From modular designs to advanced control systems, these innovations are enhancing the flexibility and efficiency of conveyor operations. The integration of sensors and automation technologies allows for real-time monitoring and control, reducing downtime and improving productivity.

The integration of smart technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is revolutionizing conveyor systems. These technologies enable predictive maintenance, optimize energy consumption, and facilitate seamless communication between different components of the industrial ecosystem. As a result, businesses can achieve higher levels of operational efficiency and cost savings.

3. The Role of Conveyor Systems in Various Industries

In the mining industry, conveyor systems are essential for transporting raw materials from extraction sites to processing facilities. The future of mining conveyors lies in automation and remote monitoring, which can enhance safety and reduce operational costs.

Conveyor systems play a crucial role in waste management by streamlining the sorting and processing of recyclable materials. Advanced sorting technologies and automated systems are set to improve the efficiency and accuracy of waste management operations.

Ports rely on conveyor systems for the efficient handling of bulk cargo. The future of port conveyors involves the integration of smart technologies to optimize loading and unloading processes, reducing turnaround times and enhancing throughput.

In the construction sector, conveyor systems facilitate the movement of materials on-site, improving project timelines and reducing labor costs. Innovations in portable and modular conveyor designs are expected to enhance the adaptability and efficiency of construction operations.

The energy sector utilizes conveyor systems for the transportation of fuel and other materials. Future developments in this area focus on enhancing energy efficiency and reducing environmental impact through the use of sustainable materials and technologies.

4. Innovations Shaping the Future of Conveyor Systems

Automation and robotics are at the forefront of conveyor system innovations. Automated guided vehicles (AGVs) and robotic arms are being integrated into conveyor systems to enhance precision and reduce human intervention, leading to safer and more efficient operations.

The IoT and data analytics are transforming conveyor systems by providing valuable insights into system performance and maintenance needs. Predictive analytics can identify potential issues before they lead to downtime, ensuring continuous operation and reducing maintenance costs.

Sustainability is a key focus for the future of conveyor systems. Innovations in energy-efficient motors, regenerative braking systems, and the use of eco-friendly materials are helping businesses reduce their carbon footprint and achieve sustainability goals.

5. Challenges and Opportunities in Conveyor System Implementation

Achieving operational efficiency is a primary challenge for businesses implementing conveyor systems. The future of conveyor systems lies in optimizing processes and reducing waste through advanced technologies and strategic planning.

System integration is crucial for the seamless operation of conveyor systems within the broader industrial ecosystem. The integration of conveyor systems with other automated processes and technologies presents both challenges and opportunities for businesses seeking to enhance their operations.

Maintenance and reliability are critical factors in the successful implementation of conveyor systems. The future of maintenance involves predictive and preventive strategies, supported by advanced monitoring technologies, to ensure the longevity and reliability of conveyor systems.

Contact CANTEC OÜ today to explore innovative and sustainable conveyor solutions tailored to your industrial needs!

Comments (0)