Welding wonders: mig/mag vs. tig techniques

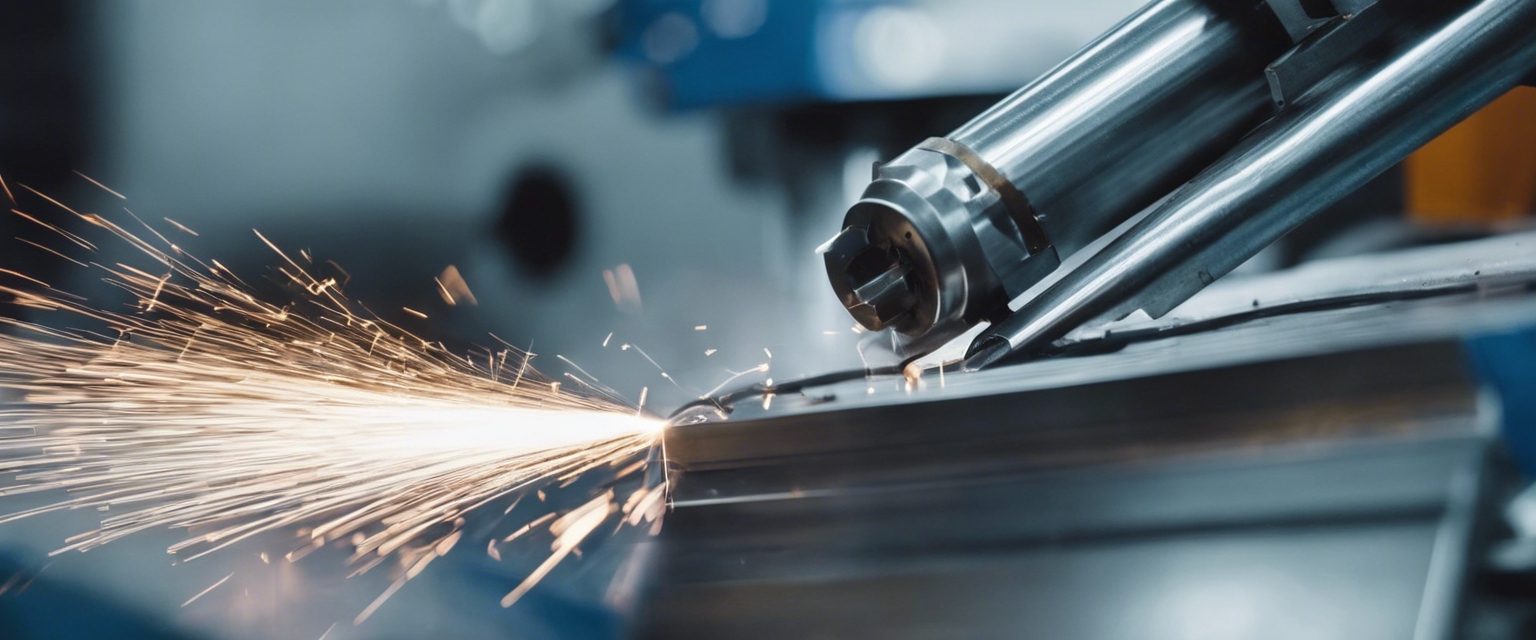

Welding is a critical process in the manufacturing, construction, and repair of metal structures and components. Among the various welding techniques, Metal Inert Gas (MIG), Metal Active Gas (MAG), and Tungsten Inert Gas (TIG) stand out for their unique capabilities and applications. This post delves into the intricacies of MIG/MAG and TIG welding, helping professionals and businesses make informed decisions for their projects.

Understanding MIG/MAG Welding

MIG/MAG welding is a versatile and widely used welding process that utilizes a continuously fed wire electrode and an inert or active gas to shield the weld pool from contamination. This technique is known for its speed and ease of use, making it a popular choice for a variety of applications.

One of the primary benefits of MIG/MAG welding is its efficiency. The continuous wire feed allows for longer welds without interruption, and the process is relatively easy to learn. Additionally, MIG/MAG welding can be used on a wide range of materials, including steel, stainless steel, and aluminum.

MIG/MAG welding is commonly used in manufacturing, automotive repair, and construction due to its adaptability and speed. It is particularly effective for welding thin to medium-thick metals and is often employed in robotic welding operations for mass production.

Exploring TIG Welding

TIG welding is a precision technique that uses a non-consumable tungsten electrode to produce the weld. The process requires the welder to use both hands—one to hold the torch and the other to add the filler metal. TIG welding is known for its high-quality, clean welds.

The precision and control offered by TIG welding make it ideal for welding complex shapes and delicate materials. It produces strong, high-quality welds with minimal spatter and is suitable for a variety of metals, including thin-gauge materials and alloys.

TIG welding is often the method of choice for critical welds that require a high degree of precision, such as in aerospace, art sculptures, and custom fabrication. It is also preferred for welding metals that are not easily handled by other welding processes, such as magnesium and titanium.

Comparing MIG/MAG and TIG Welding

While MIG/MAG welding is faster and more efficient for longer welds on thicker materials, TIG welding offers greater precision and control for detailed work on thinner materials. The choice between the two methods depends on the specific requirements of the project, including the type of metal, the desired finish, and the level of detail needed.

Material thickness and type play a significant role in determining whether MIG/MAG or TIG welding is more appropriate. MIG/MAG is generally better suited for steel and aluminum, while TIG excels with a wider range of metals, including non-ferrous metals and alloys.

Ultimately, the decision between MIG/MAG and TIG welding techniques should be based on the specific needs of the project. Factors such as production volume, weld quality, and material type should all be considered to ensure the best outcome for your welding tasks.

Comments (0)