The future of metal fabrication: cnc laser technology

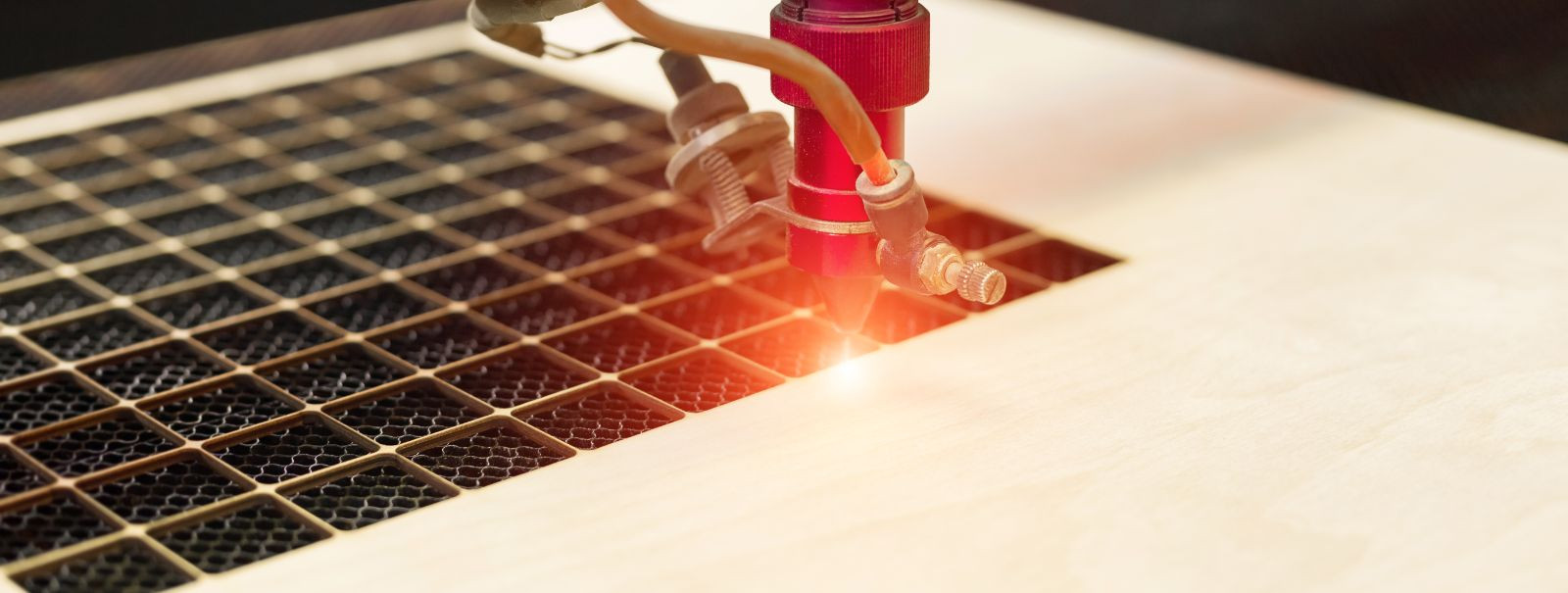

CNC (Computer Numerical Control) laser technology represents a significant leap forward in the field of metal fabrication. By harnessing the power of high-energy laser beams, CNC laser machines can cut, engrave, and mark a wide range of materials with unparalleled precision. This technology is driven by sophisticated software that allows for intricate designs and consistent repeatability.

Metal fabrication has come a long way from traditional manual methods to automated processes. The introduction of CNC machinery has revolutionized the industry, allowing for faster production times, reduced human error, and the ability to produce complex shapes that were once impossible to achieve.

The Impact of CNC Laser Technology on Metal Fabrication

The precision of CNC laser cutting is unmatched, producing clean, burr-free cuts that require minimal finishing. Efficiency is also greatly enhanced, as CNC lasers can operate continuously with little downtime, translating to higher throughput and faster turnaround times for projects.

CNC lasers can work with a diverse range of materials, including various metals, plastics, and composites. The technology's high precision also leads to optimal material utilization, significantly reducing waste and lowering material costs.

The flexibility of CNC laser technology opens up new possibilities in design. Fabricators can now undertake complex projects with intricate details and customization options that were previously unattainable, giving them a competitive edge in the market.

Adopting CNC Laser Technology in the Baltic Region

The Baltic region, with its robust industrial sector, is ripe for the integration of advanced manufacturing technologies like CNC laser systems. Estonia, in particular, has shown a keen interest in adopting these innovations to enhance its manufacturing capabilities.

While the benefits of CNC laser technology are clear, the adoption process can be challenging. Initial investment costs, training requirements, and the need to update existing workflows are significant considerations for Baltic businesses. However, the long-term advantages and potential for increased competitiveness present compelling opportunities for forward-thinking companies.

Investing in CNC Laser Technology

Investing in CNC laser equipment is a strategic decision that requires a thorough cost-benefit analysis. The initial outlay may be substantial, but the increase in production efficiency, reduction in waste, and ability to take on more complex projects can lead to significant financial gains over time.

Implementing CNC laser technology necessitates a skilled workforce. Investing in training and skill development is essential to maximize the potential of the technology and ensure a smooth transition to more advanced manufacturing processes.

For businesses in the Baltic region, the long-term advantages of integrating CNC laser technology into their operations are manifold. Improved product quality, enhanced production capabilities, and the ability to respond quickly to market demands are just a few of the benefits that can sustain and grow a business in today's competitive landscape.

Comments (0)