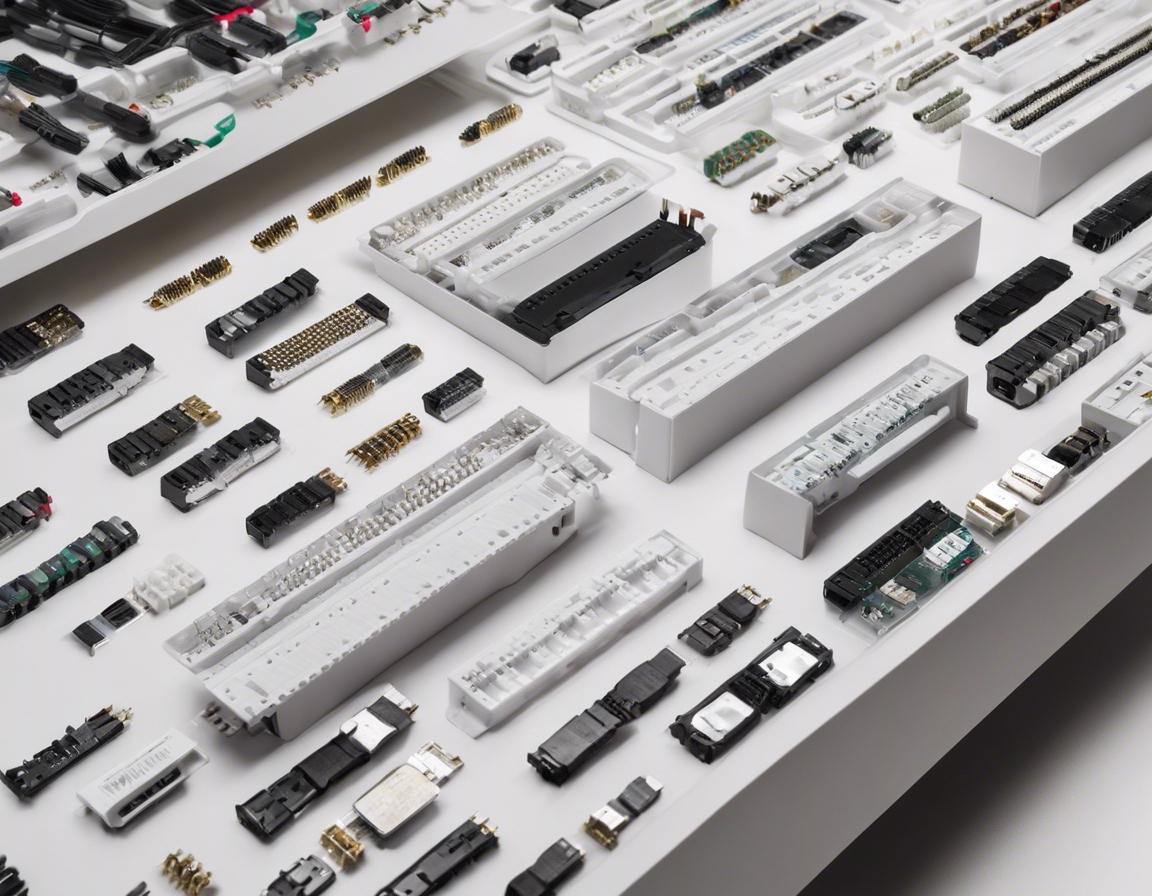

The art of cable manufacturing: a behind-the-scenes look

In today's interconnected world, the role of cables cannot be overstated. From powering automotive engines to transmitting data across global IT infrastructures, cables are the lifelines of modern technology. For professionals in the automotive, electronics, IT, and audio-visual industries, understanding the intricacies of cable manufacturing is crucial for ensuring reliability and performance in their applications.

Cable manufacturing is a complex art that combines engineering precision with material science. It's a process that requires meticulous attention to detail and an unwavering commitment to quality. This post offers a deep dive into the stages of cable production, the technologies involved, and the customization options that cater to specialized industry requirements.

The Journey of Cable Production

The cable manufacturing process begins with design and engineering. Here, the specifications of the cable are determined, including its dimensions, electrical properties, and intended use. SPINMAN OÜ's team of engineers uses advanced software to create blueprints that ensure the highest level of performance and compliance with industry standards.

Choosing the right materials is essential for the cable's functionality. Conductors, insulators, and jacketing materials are selected based on their electrical properties, durability, and environmental resistance. SPINMAN OÜ sources high-quality materials to guarantee the longevity and reliability of its cables.

Extrusion is the process where the conductor material is shaped into wires. Precision machinery heats and shapes the metal, ensuring consistent thickness and quality. SPINMAN OÜ's state-of-the-art extrusion equipment allows for the production of cables with exacting tolerances.

Once the individual wires are created, they are assembled into a cable. Cabling and twisting are critical for the cable's flexibility and strength. SPINMAN OÜ employs advanced cabling techniques to produce cables that can withstand the rigors of their intended environments.

Insulation and jacketing are what protect the cable's conductive core from environmental factors and electrical interference. SPINMAN OÜ uses materials that provide optimal insulation and durability, ensuring that cables can operate effectively in various conditions.

Every cable is rigorously tested to ensure it meets stringent quality standards. SPINMAN OÜ's testing protocols include electrical testing, mechanical stress testing, and environmental exposure testing to ensure each cable's performance and safety.

Advanced Technologies in Cable Manufacturing

Automation plays a significant role in modern cable manufacturing. It enhances precision and consistency while allowing for higher production volumes. SPINMAN OÜ leverages automated systems to maintain the highest levels of accuracy and efficiency.

The cable industry is constantly evolving, with new materials and sustainable practices being introduced. SPINMAN OÜ is at the forefront of these innovations, incorporating eco-friendly materials and processes to reduce environmental impact.

The Role of Customization in Cable Manufacturing

Customization is key to meeting the unique needs of different industries. SPINMAN OÜ works closely with clients to develop cables that meet their specific requirements, whether for automotive, IT infrastructure, or audio-visual applications.

At SPINMAN OÜ, the approach to custom cable solutions is client-centric. The team collaborates with clients to understand their challenges and deliver tailor-made cables that enhance the performance and reliability of their systems.

Comments (0)