5 ways cnc milling can improve your product design

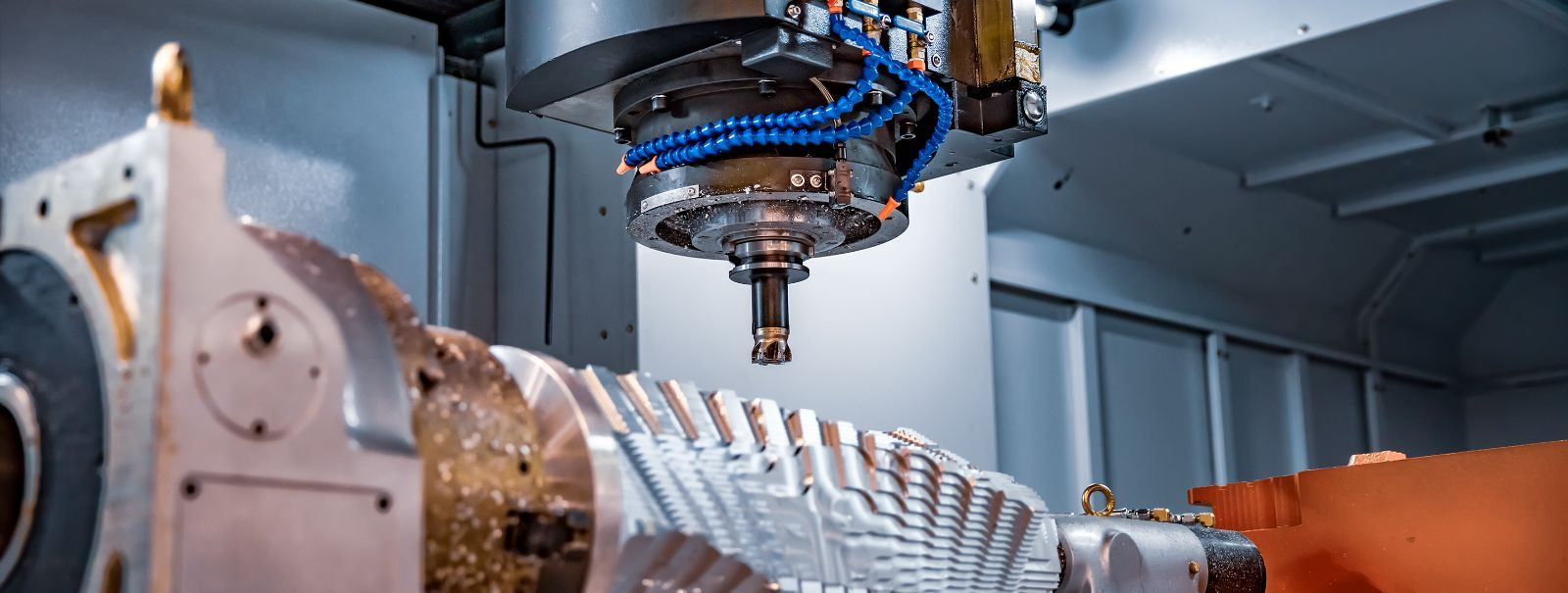

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that uses computer-controlled machine tools to remove material from a solid block, known as the workpiece, to produce a custom-designed part or product. This technology has revolutionized the way manufacturers approach the design and production of metal components.

Product design is critical in determining the functionality, aesthetics, and overall success of a product in the market. A well-designed product not only meets the needs of the user but also contributes to the efficiency and cost-effectiveness of the manufacturing process.

1. Enhanced Precision and Consistency

CNC milling machines are capable of producing parts with complex geometries and tight tolerances. The precision of CNC milling ensures that every detail of the product design is accurately replicated, resulting in components that fit together perfectly and function as intended.

One of the key advantages of CNC milling is its repeatability. Once a design is programmed into the CNC machine, it can produce the same part consistently without deviation, which is essential for mass production and maintaining quality standards.

2. Material Versatility

CNC milling machines can work with a wide variety of materials, including metals, plastics, and composites. This flexibility allows designers to choose the most appropriate material for their product based on the required properties, such as strength, weight, and corrosion resistance.

Understanding the properties of different materials and how they interact with the milling process is crucial for optimizing product performance. CNC milling can help in selecting the right material that enhances the product's functionality and longevity.

3. Improved Surface Finish and Aesthetics

CNC milling can achieve superior surface finishes that are smooth to the touch and visually appealing. This is particularly important for products that require a high-quality look and feel, as well as for components that need to minimize friction or wear.

The ability to produce fine details and smooth finishes allows designers to incorporate aesthetic elements into their product without compromising on quality or functionality.

4. Design Complexity and Feature Integration

The advanced capabilities of CNC milling machines enable the creation of parts with intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for product innovation and complexity.

With CNC milling, it is possible to integrate multiple features into a single machined part, reducing the need for additional components and assembly. This not only simplifies the design but also can lead to a more robust and lightweight product.

5. Rapid Prototyping and Iterative Design

Rapid prototyping is a process where a prototype or working model of a product is quickly fabricated using CNC milling. This allows designers to test and refine their designs in a short period, significantly speeding up the development process.

The ease of making changes to the CNC program allows for iterative design, where a product can be continuously improved upon with each prototype. This iterative process ensures that the final design is as close to perfection as possible, meeting all the desired specifications and requirements.

Comments (0)