The future of eco-friendly concrete in construction

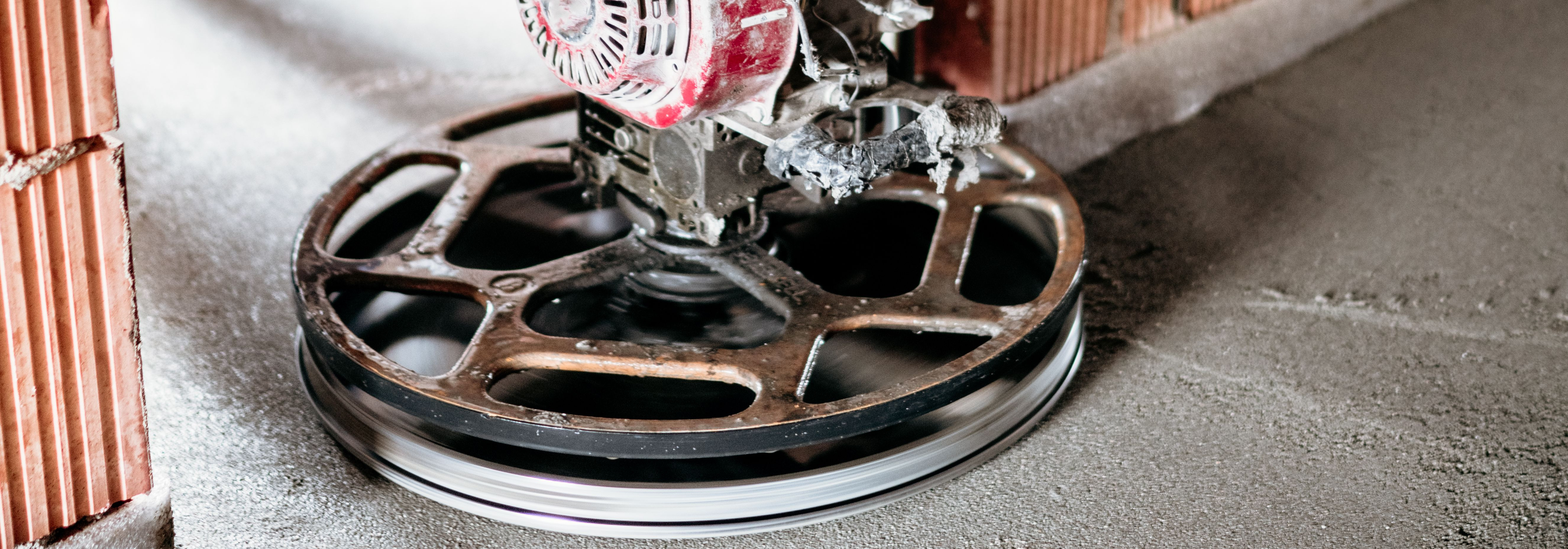

As the construction industry continues to evolve, the demand for sustainable building materials has never been more critical. Eco-friendly concrete, also known as green concrete, is at the forefront of this transformation. It is designed to reduce the environmental impact of construction by incorporating sustainable practices and materials.

The Importance of Sustainable Construction Practices

With the global push towards reducing carbon emissions and conserving natural resources, sustainable construction practices have become essential. The construction industry is a significant contributor to environmental degradation, and adopting eco-friendly materials like green concrete is a vital step towards mitigating this impact.

Innovations in Eco-Friendly Concrete

One of the most promising innovations in eco-friendly concrete is the use of recycled materials. By incorporating industrial by-products such as fly ash, slag, and recycled aggregates, the carbon footprint of concrete production can be significantly reduced. These materials not only enhance the sustainability of concrete but also improve its performance characteristics.

Another groundbreaking development is the integration of carbon capture and utilization technologies in concrete production. This process involves capturing carbon dioxide emissions and using them as a raw material in the concrete mix. This not only reduces greenhouse gas emissions but also enhances the strength and durability of the concrete.

Traditional Portland cement is a major source of carbon emissions in concrete production. Researchers are exploring alternative binders, such as geopolymers and magnesium-based cements, which offer a lower carbon footprint and improved sustainability. These binders can replace or supplement traditional cement, leading to more eco-friendly concrete solutions.

Benefits of Eco-Friendly Concrete

Eco-friendly concrete significantly reduces the environmental impact of construction projects. By utilizing recycled materials and alternative binders, it decreases the demand for virgin resources and lowers carbon emissions, contributing to a more sustainable construction industry.

While the initial cost of eco-friendly concrete may be higher, the long-term economic benefits are substantial. Reduced energy consumption, lower maintenance costs, and potential tax incentives for sustainable building practices can lead to significant savings over the lifespan of a construction project.

Eco-friendly concrete is not only sustainable but also offers enhanced performance and durability. The use of innovative materials and technologies can result in concrete that is stronger, more resilient, and better suited to withstand environmental challenges, ensuring the longevity of construction projects.

Challenges and Considerations

One of the primary challenges in adopting eco-friendly concrete is the cost. While the long-term benefits are clear, the initial investment can be a barrier for some construction companies. However, as technology advances and economies of scale are realized, these costs are expected to decrease.

Compliance with environmental regulations and standards is crucial for the adoption of eco-friendly concrete. Construction companies must navigate a complex landscape of regulations to ensure that their projects meet sustainability criteria, which can be a daunting task.

Despite its benefits, eco-friendly concrete faces challenges in market acceptance. Traditional construction practices are deeply ingrained, and convincing stakeholders to adopt new materials and methods requires education and demonstration of the tangible benefits of green concrete.

The Role of ECO-BETOON OÜ in Advancing Eco-Friendly Concrete

ECO-BETOON OÜ is committed to leading the charge in sustainable construction practices. By investing in research and development, the company is at the forefront of producing high-quality, eco-friendly concrete solutions. With a focus on innovation and sustainability, ECO-BETOON OÜ is poised to play a pivotal role in shaping the future of the construction industry.

Comments (0)