5 ways cnc technology is transforming manufacturing

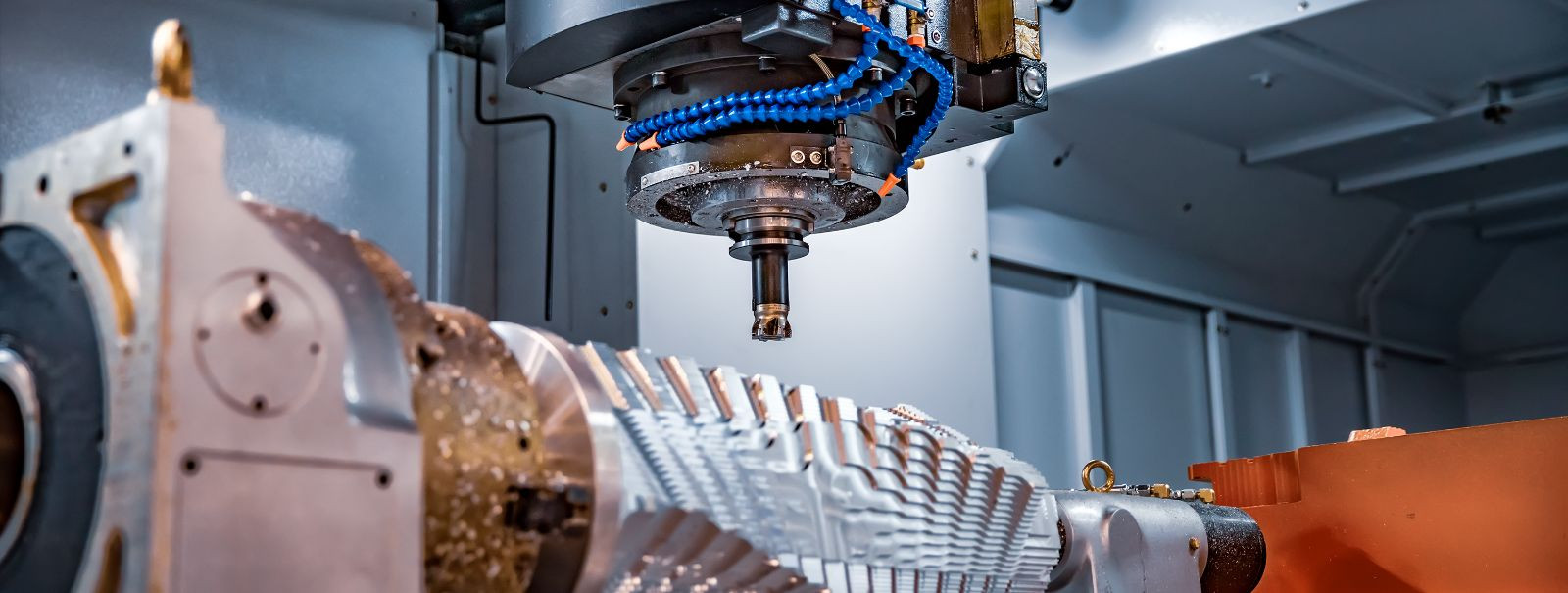

Computer Numerical Control (CNC) technology has revolutionized the manufacturing industry by enhancing the precision, efficiency, and flexibility of production processes. CNC machines are now indispensable tools in the production of complex parts and components across various sectors.

1. Enhanced Precision and Consistency

CNC technology has set new standards for precision in manufacturing. With computer-controlled machining, products are produced with exacting accuracy, leading to significant improvements in quality control and a reduction in human error.

By automating the machining process, CNC ensures that each part is produced to the same high standards, meeting the stringent requirements of industries such as aerospace and medical devices.

The precision of CNC machines minimizes the variability introduced by manual operations, ensuring consistent quality and reducing the need for rework.

2. Increased Production Efficiency

CNC machines streamline the manufacturing process by automating repetitive tasks, which leads to improved workflow and increased throughput.

Automation allows for continuous operation without fatigue, enabling manufacturers to maintain a steady pace of production around the clock.

The integration of CNC machines into production lines optimizes the manufacturing process, reducing cycle times and increasing output.

3. Flexibility in Design and Customization

CNC technology empowers manufacturers to produce parts with complex geometries and intricate details that would be difficult or impossible to achieve with traditional methods.

Advanced CNC machines can handle a variety of materials and surface finishes, allowing for the creation of highly customized and complex designs.

With CNC, manufacturers can easily adjust production parameters to meet specific client needs, enhancing the ability to offer tailored solutions.

4. Cost-Effectiveness Over Time

While the initial investment in CNC machinery may be significant, the long-term benefits include reduced labor costs, lower material waste, and minimal downtime.

Precision machining means less material is wasted during the production process, contributing to cost savings and environmental sustainability.

The efficiency and productivity gains from CNC technology translate into a strong return on investment over time, making it a financially sound choice for manufacturers.

5. Integration with Advanced Manufacturing Systems

CNC technology is at the forefront of the fourth industrial revolution, integrating seamlessly with advanced manufacturing systems such as Industry 4.0, the Internet of Things (IoT), and data analytics.

CNC machines are increasingly being networked with other digital systems, enabling smart manufacturing practices and real-time monitoring of production processes.

The data generated by CNC operations can be analyzed to optimize performance, predict maintenance needs, and enhance overall productivity.

Comments (0)