The art of cnc cutting: precision and innovation

Computer Numerical Control (CNC) cutting is a sophisticated manufacturing process that utilizes computerized controls and machine tools to remove layers from a material to produce custom-designed parts. This technology has revolutionized the manufacturing industry by providing unparalleled precision and efficiency.

In today's fast-paced industrial landscape, CNC cutting is indispensable. It allows manufacturers to produce complex parts with high precision, reducing waste and increasing productivity. This technology is crucial for industries that demand exact specifications and high-quality outputs.

The Precision of CNC Cutting

CNC cutting machines are renowned for their ability to produce parts with exceptional accuracy and consistency. The precision of CNC cutting is achieved through advanced software that controls the cutting tools with exacting detail, ensuring each piece is identical to the last.

The backbone of CNC cutting is its advanced software, which allows for intricate designs and complex geometries. This technology enables manufacturers to push the boundaries of what is possible, creating parts that were once thought impossible to produce.

Innovations in CNC Cutting

Recent innovations in CNC cutting include the integration of AI and machine learning, which enhance the capabilities of CNC machines by optimizing cutting paths and improving efficiency. These advancements are paving the way for smarter, more autonomous manufacturing processes.

CNC cutting is increasingly being integrated with other technologies such as 3D printing and laser cutting. This synergy allows for more versatile manufacturing solutions, enabling companies to meet diverse production needs with greater flexibility.

Applications of CNC Cutting in Various Industries

In industrial manufacturing, CNC cutting is used to produce everything from automotive parts to aerospace components. Its precision and reliability make it ideal for industries where safety and performance are paramount.

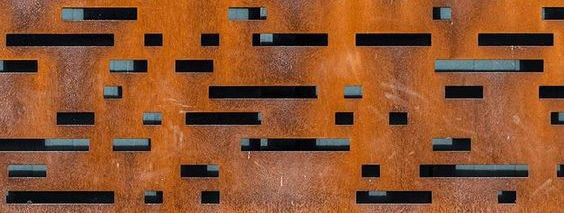

The construction industry benefits from CNC cutting through the production of custom metalwork and structural components. This technology allows for the creation of intricate designs that enhance both the functionality and aesthetics of buildings.

Architectural firms utilize CNC cutting to bring innovative designs to life. From decorative facades to complex structural elements, CNC cutting provides architects with the tools to realize their creative visions with precision and efficiency.

Benefits of CNC Cutting

CNC cutting is a cost-effective solution for manufacturers, as it reduces material waste and minimizes the need for manual labor. This efficiency translates into lower production costs and faster turnaround times.

With a growing emphasis on sustainability, CNC cutting offers a more environmentally friendly manufacturing option. Its precision reduces material waste, and its ability to work with sustainable materials aligns with the industry's shift towards greener practices.

Challenges and Solutions in CNC Cutting

Custom metal fabrication can present challenges such as complex designs and tight tolerances. However, CNC cutting addresses these issues by providing the precision and flexibility needed to meet specific requirements.

Production hurdles such as high-volume demands and intricate designs can be overcome with CNC cutting. Its advanced technology and automation capabilities ensure that manufacturers can meet these challenges head-on, delivering high-quality products efficiently.

Comments (0)