The art of metal structure assembly

Metal structures form the backbone of modern infrastructure. From towering skyscrapers to expansive bridges, the strength and durability of metal make it an indispensable material in construction. The assembly of these structures is a complex art that combines engineering precision with skilled craftsmanship.

Over the years, metal assembly has evolved from rudimentary forging and welding to sophisticated techniques that ensure precision and efficiency. The advancements in technology have paved the way for innovative methods that meet the growing demands of complex architectural designs.

Key Components of Metal Structure Assembly

Choosing the right material is critical for the success of any metal structure. Steel, aluminum, and alloys each have unique properties that determine their suitability for different applications. Understanding these materials' tensile strength, flexibility, and corrosion resistance is essential for optimal design and longevity.

The design phase is where the vision of a structure takes shape. Engineers must consider load-bearing capacities, environmental stresses, and aesthetic elements to create blueprints that are both functional and visually appealing. Advanced software tools are now used to simulate and optimize designs before assembly begins.

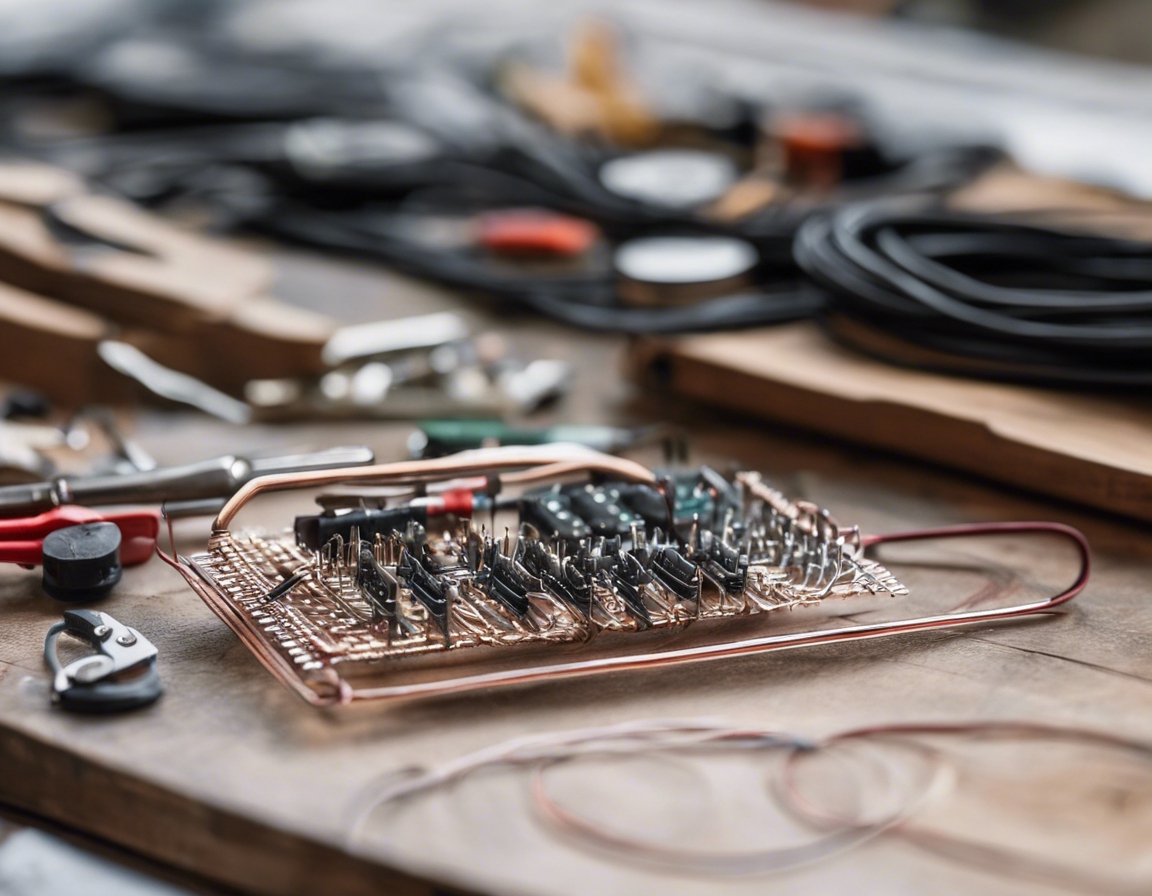

Fabrication involves cutting, bending, and assembling metal components to form the final structure. This process requires precision machinery and skilled technicians to ensure each piece meets stringent specifications.

Advanced Techniques in Metal Structure Assembly

Laser cutting, water jet cutting, and plasma cutting are some of the precision techniques used to shape metal components with exacting accuracy. Joining methods such as welding, bolting, and riveting are then employed to assemble these pieces into a cohesive structure.

The integration of automation and robotics in metal assembly has revolutionized the industry. These technologies increase efficiency, reduce human error, and ensure consistent quality across large-scale projects.

Quality control is paramount in metal structure assembly. Non-destructive testing methods like ultrasonic testing, magnetic particle inspection, and x-ray are used to detect any flaws or weaknesses in the assembly process.

Challenges in Metal Structure Assembly

As architectural designs become more intricate, the assembly of metal structures grows increasingly challenging. It requires a deep understanding of both the materials and the intended design to execute complex projects successfully.

Maintaining the structural integrity of metal assemblies is crucial for safety and longevity. Engineers and assembly technicians must adhere to strict building codes and standards to prevent structural failures.

Environmental factors such as wind, temperature changes, and seismic activity can impact the assembly and long-term stability of metal structures. It is essential to account for these variables during the design and assembly phases.

Best Practices for Efficient Metal Structure Assembly

Effective project management ensures that metal assembly projects are completed on time and within budget. Detailed planning is necessary to coordinate the various stages of assembly and to manage resources effectively.

Training a skilled workforce is vital for the successful assembly of metal structures. Additionally, a strong emphasis on safety can prevent accidents and ensure a smooth construction process.

Logistical planning is crucial for transporting materials and coordinating on-site assembly. Efficient logistics can minimize downtime and streamline the construction process, leading to better outcomes for complex projects.

Comments (0)