5 ways high-quality metals can elevate your manufacturing

High-quality metals are the backbone of manufacturing industries, providing the strength, durability, and precision needed for a wide range of applications. In this post, we'll explore five key ways that premium metals can transform your manufacturing processes and products.

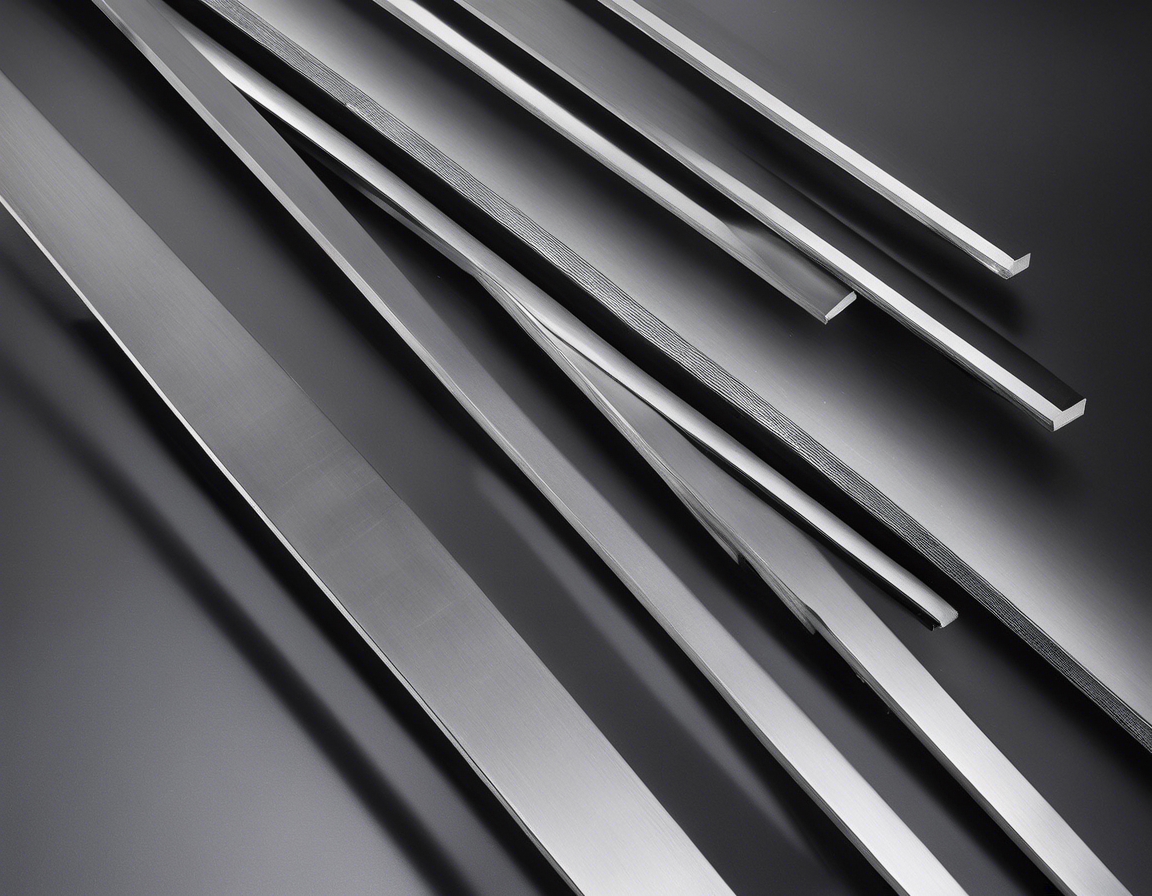

1. Enhanced Durability and Longevity

Investing in high-quality metals means your components are less likely to succumb to the daily rigors of industrial use. This resistance to wear and tear ensures that machinery and parts function reliably over time, reducing the need for frequent replacements.

While the initial investment in superior metals may be higher, the long-term savings are significant. Durable metals lead to fewer breakdowns, less downtime, and reduced maintenance costs, ultimately contributing to a healthier bottom line.

2. Superior Performance Under Extreme Conditions

High-quality metals can withstand extreme temperatures without losing their structural integrity, making them ideal for use in demanding environments such as energy production or aerospace applications.

Corrosion can lead to catastrophic failures in manufacturing. Premium metals often come with inherent corrosion resistance or can be treated to withstand corrosive environments, ensuring longevity and reliability.

3. Precision and Customization

High-precision metals are essential for industries that require strict adherence to specifications. Quality metals can be engineered to meet exacting standards, ensuring that your products are compliant and competitive.

With high-quality metals, the possibilities for customization are vast. Whether you need unique alloys or specific shapes and sizes, premium metal suppliers can provide tailored solutions that fit your unique manufacturing needs.

4. Aesthetic Appeal and Finishing Options

The right metal finishes not only protect but also enhance the appearance of your products. High-quality metals offer a variety of finishing options, from anodizing to powder coating, to achieve the desired aesthetic and functional properties.

Utilizing distinctive metal finishes can serve as a branding tool, setting your products apart in the marketplace. This differentiation is crucial for companies looking to establish a strong brand identity and market presence.

5. Sustainability and Compliance

More than ever, sustainability is a critical consideration in manufacturing. High-quality metals often come from recycled materials and are themselves recyclable, contributing to a circular economy and reducing environmental impact.

Compliance with environmental and safety regulations is non-negotiable. Premium metals ensure that your manufacturing processes meet the latest standards, avoiding costly fines and preserving your reputation.

Comments (0)