Maximizing efficiency with electric actuators

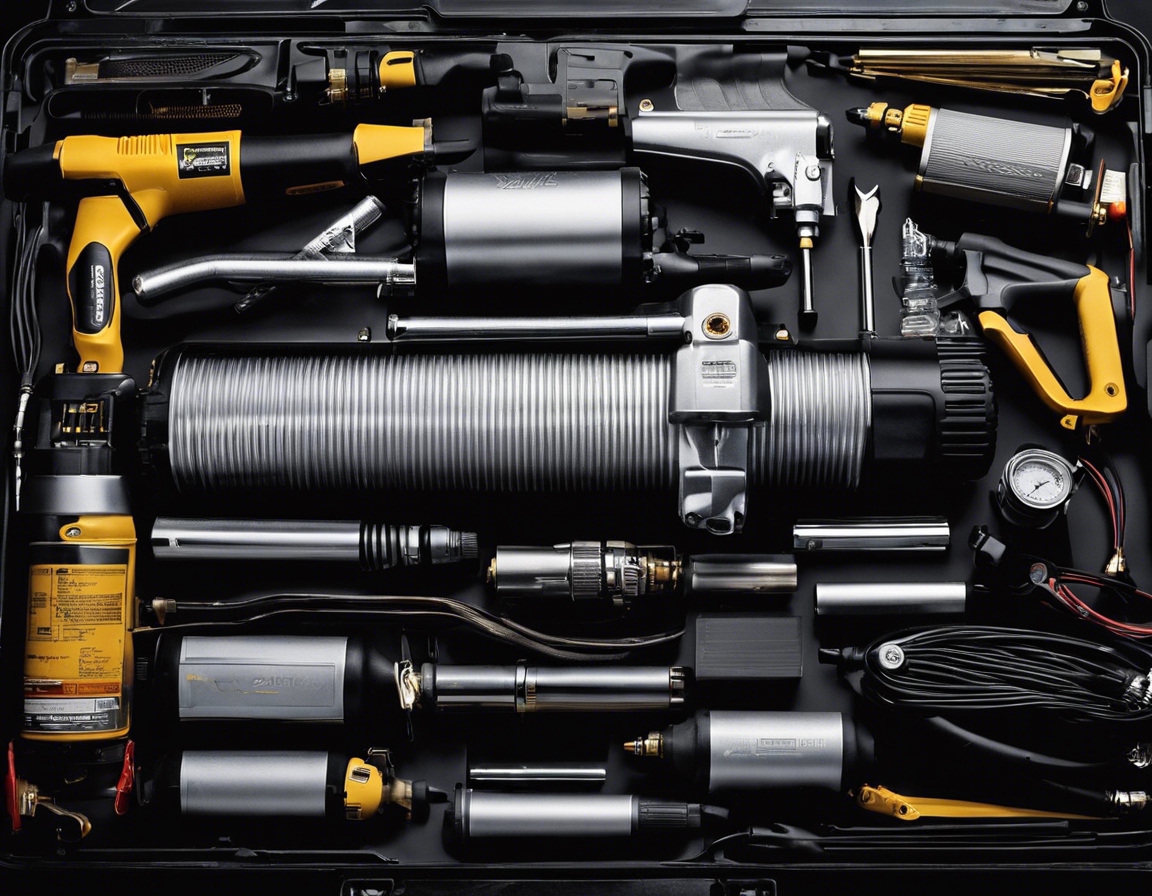

Electric actuators are devices that convert electrical energy into mechanical torque, facilitating controlled movements in various applications. They are integral components in modern automation systems, offering precision and efficiency.

Compared to pneumatic or hydraulic actuators, electric actuators boast higher energy efficiency, better control, and easier integration with digital control systems. They also require less maintenance and are more environmentally friendly.

Key Features of Electric Actuators

One of the most significant benefits of electric actuators is their ability to achieve precise positioning and speed control, which is essential for applications requiring high levels of accuracy.

Electric actuators consume power only when in operation, reducing energy waste and operational costs. This makes them a sustainable choice for businesses focused on energy conservation.

With fewer moving parts than traditional actuators, electric actuators are less prone to wear and tear, resulting in a longer service life and consistent performance.

Applications of Electric Actuators in Various Industries

In the construction sector, electric actuators are used to control machinery, such as cranes and lifts, enhancing safety and efficiency on the job site.

For electronics manufacturers, precision is paramount. Electric actuators provide the accuracy needed for assembling small components and testing electronic devices.

Industrial automation relies heavily on electric actuators for tasks like assembly line control, robotic arm movement, and process automation, streamlining production and reducing labor costs.

Integration into Existing Systems

Integrating electric actuators into existing systems can pose challenges, such as compatibility with current machinery and software. However, with careful planning and the right expertise, these hurdles can be overcome.

Best practices for integrating electric actuators include conducting a thorough analysis of current systems, consulting with experts, and choosing actuators with flexible programming capabilities.

Choosing the Right Electric Actuator

When selecting an electric actuator, it's crucial to understand the specific requirements of your application, including load capacity, speed, stroke length, and environmental conditions.

Many electric actuators offer customization options to meet unique application needs. SMC AUTOMATION OÜ provides tailored solutions that can fit specific operational demands.

Maintenance and Troubleshooting

Regular maintenance of electric actuators involves checking for wear, ensuring proper lubrication, and updating software. These practices help prevent downtime and extend the life of the actuator.

Common issues with electric actuators may include overheating, noise, or loss of precision. Troubleshooting typically starts with checking electrical connections, settings, and components for any signs of malfunction.

Comments (0)