Understanding the benefits of 4-axis milling

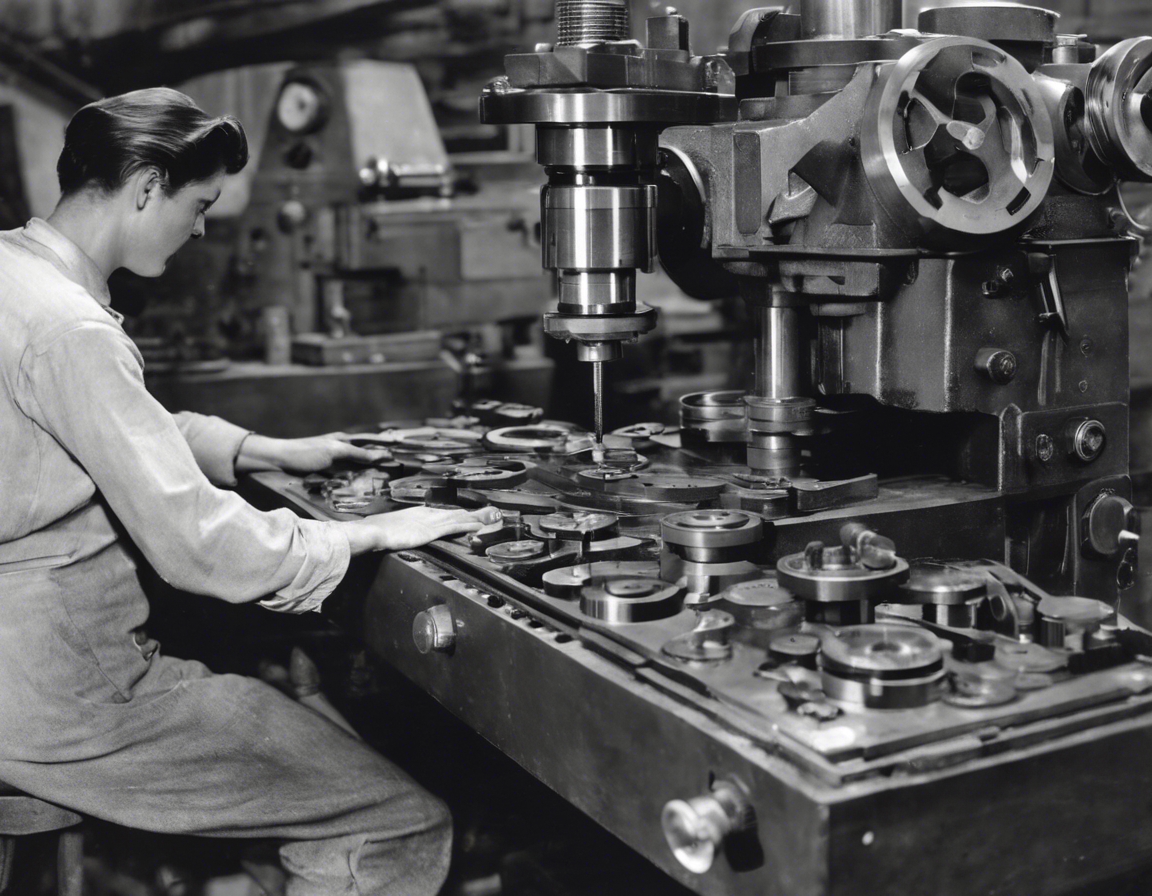

4-Axis milling is a powerful CNC (Computer Numerical Control) machining process that adds a rotational axis to the traditional 3-axis milling approach, allowing for more complex and detailed workpieces. This additional axis enables the workpiece to be rotated, which means that multiple sides of the part can be machined in a single setup.

While 3-axis milling is proficient for many operations, 4-axis milling surpasses it by providing the ability to produce more intricate designs with higher precision. This is particularly beneficial for components that require complex geometries and features that cannot be achieved with a 3-axis setup.

Advantages of 4-Axis Milling

One of the primary benefits of 4-axis milling is the ability to create complex shapes and high-precision parts with ease. The additional axis allows for the creation of features that are not possible with traditional milling methods, such as undercuts, intricate profiles, and deep cavity work.

4-axis milling machines can complete parts faster due to their ability to perform multiple operations in a single setup. This reduces the need for additional fixtures and tool changes, leading to shorter production times and increased throughput.

The 4-axis capability enables the machining of parts from various angles without the need for repositioning, which greatly expands the types of work that can be done on a single machine. This versatility is crucial for custom and specialized production runs.

Although the initial investment in 4-axis milling technology may be higher than traditional milling machines, the long-term benefits include reduced labor costs, lower fixture costs, and minimized waste, all contributing to a more cost-effective production process over time.

Applications of 4-Axis Milling in Industry

The aerospace industry benefits greatly from 4-axis milling, as it requires parts with tight tolerances and complex geometries. 4-axis machines are capable of producing the intricate components needed for aerospace applications with the precision required.

In the automotive sector, 4-axis milling is used to create a variety of components, from engine parts to custom modifications. The technology's precision and efficiency make it ideal for the high standards of the automotive industry.

Engineering firms and prototyping services utilize 4-axis milling for its ability to quickly produce complex prototypes and end-use parts. This accelerates the development process and allows for more iterative and innovative design testing.

Technical Considerations for 4-Axis Milling

When considering 4-axis milling, it's important to understand the specific capabilities of the machine, including its size, power, and the types of rotational movements it can perform. This will determine the complexity of the parts that can be produced.

Tooling choices and material selection are critical for successful 4-axis milling operations. The right combination ensures that parts are machined efficiently and to the required standards.

Advanced CAM (Computer-Aided Manufacturing) software is essential for programming 4-axis milling machines. This software allows for the precise control needed to take full advantage of the machine's capabilities.

Choosing the Right Milling Solution

Before selecting a 4-axis milling solution, it's crucial to assess the specific needs of the project, including the complexity of the parts, the materials to be used, and the production volume.

Choosing a provider with the right expertise and equipment is essential for achieving the desired results. A provider like SEROMAR OÜ, with a proven track record in 4-axis milling, can ensure that your project is completed to the highest standards.

Comments (0)