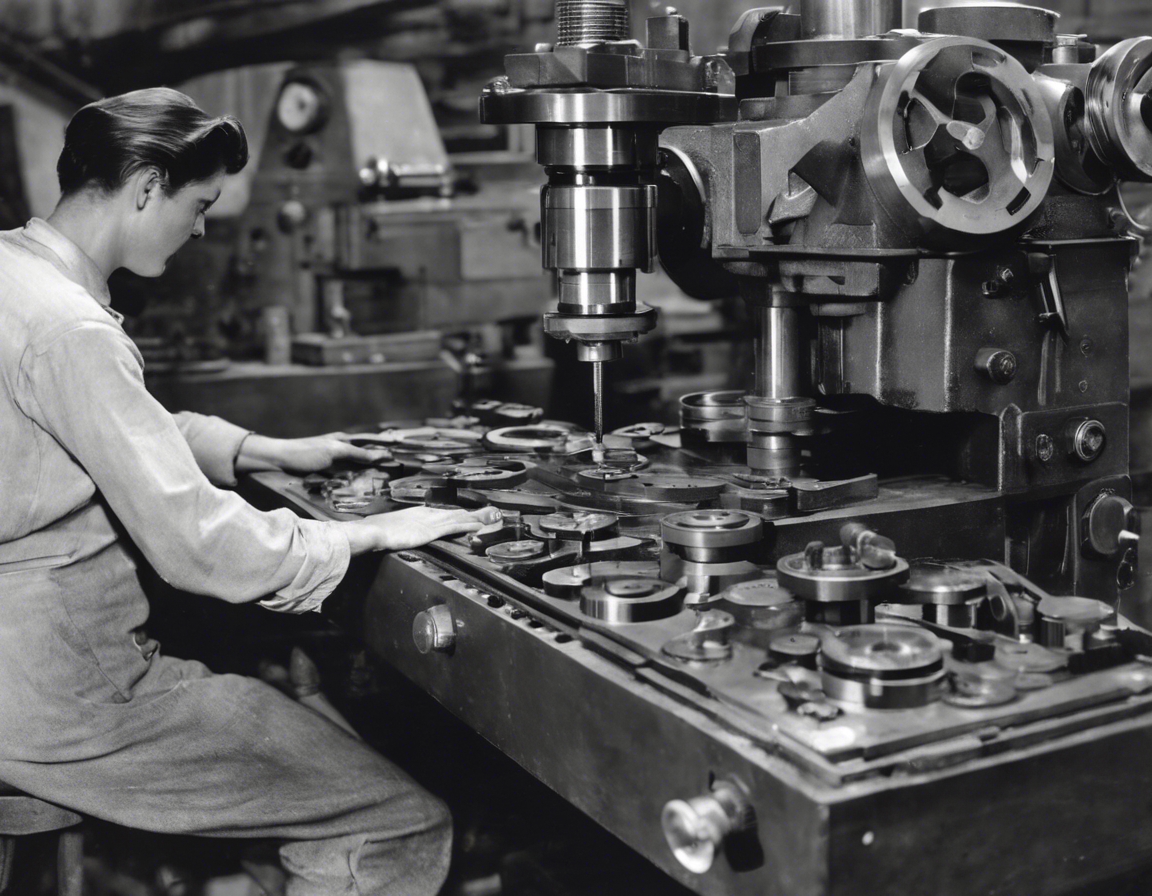

5 ways cnc machining is transforming the metal industry

The advent of Computer Numerical Control (CNC) machining has marked a significant milestone in the evolution of the metal industry. By automating the control of machine tools through precisely programmed computer systems, CNC machining has revolutionized the way metal components are manufactured.

CNC technology has come a long way since its inception. The continuous advancements in CNC machinery have expanded the capabilities of metal fabricators, allowing for the creation of parts with intricate designs that were once deemed impossible.

The metal industry has seen a substantial transformation due to CNC machining. This technology has not only improved the quality and precision of metal parts but has also increased efficiency and reduced production costs.

1. Enhanced Precision and Consistency

Precision is paramount in the metal industry, especially for sectors such as aerospace, automotive, and specialized engineering. The slightest deviation can lead to significant performance issues or even catastrophic failures.

CNC machines are capable of producing parts with extremely tight tolerances, ensuring consistent quality across large production runs. The use of advanced software allows for precise control over the machining process, resulting in unparalleled accuracy.

2. Increased Production Speed and Efficiency

Traditional machining methods are often time-consuming and labor-intensive. CNC machining, on the other hand, streamlines the production process by minimizing manual intervention and allowing for continuous operation.

With CNC machining, production cycles are significantly faster, which means that manufacturers can meet tight deadlines and respond quickly to market demands. This efficiency translates into cost savings and a competitive edge in the industry.

3. Complex Component Fabrication

CNC machines are not limited by the complexity of the parts they can produce. They can execute intricate cuts and detailed work that would be difficult or impossible to achieve with manual machining.

From intricate aerospace components to complex automotive parts, CNC machining has enabled the production of highly complex designs that meet strict industry standards and tolerances.

4. Improved Material Utilization and Waste Reduction

Efficient material utilization is another benefit of CNC machining. By optimizing cutting paths and reducing material handling, CNC machines minimize scrap and make the most out of raw materials.

The reduction in waste not only saves costs but also aligns with the growing emphasis on sustainable manufacturing practices, making CNC machining an environmentally friendly option.

5. Integration with Advanced Technologies

CNC machining is at the forefront of adopting Industry 4.0 and the Internet of Things (IoT), which allows for smarter production processes and data-driven decision-making.

The integration of artificial intelligence (AI) and automation with CNC machining is paving the way for even greater efficiencies and capabilities, setting the stage for the future of the metal industry.

Comments (0)