The future of mechanical engineering in the wood industry

The wood industry, a cornerstone of manufacturing and construction, has long relied on mechanical engineering to innovate and streamline its processes. As we look to the future, the role of mechanical engineering is poised to evolve, driven by technological advancements and the need for sustainability.

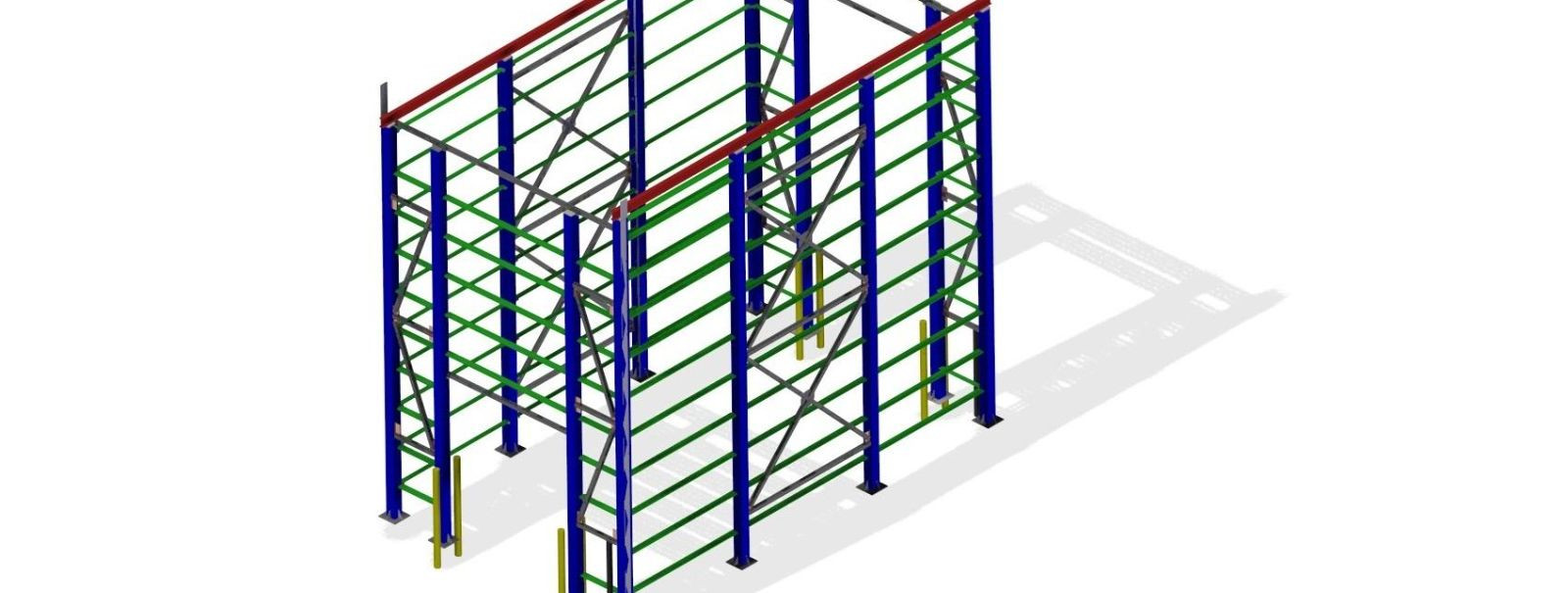

Mechanical engineering in the wood industry encompasses a range of applications, from sawmill equipment to CNC routers. The focus has been on improving precision, speed, and safety, while reducing costs.

Innovations in mechanical engineering are crucial for the wood industry to meet the growing demand for high-quality, sustainable products. They enable companies to maintain a competitive edge in a rapidly changing market.

Emerging Technologies Shaping the Future

Automation and robotics are revolutionizing wood processing by increasing efficiency and consistency. Advanced robotic systems can handle complex tasks with precision, reducing the need for manual labor.

The development of new materials and composites offers enhanced durability and performance for machinery, leading to longer lifespans and reduced maintenance.

3D printing is transforming the way parts and components are produced, allowing for rapid prototyping and the creation of complex geometries that were previously impossible to achieve.

AI and machine learning are being integrated into wood processing equipment to optimize operations, predict maintenance needs, and improve quality control.

Environmental Considerations and Sustainability

Energy-efficient machinery is becoming a priority, with a focus on reducing the carbon footprint of wood processing operations.

The industry is increasingly adopting sustainable sourcing practices and utilizing materials that minimize environmental impact.

Innovative technologies are being developed to reduce waste and enhance recycling capabilities in the wood industry, promoting a circular economy.

Challenges and Opportunities

The integration of new technologies requires a workforce skilled in both traditional woodworking and modern engineering practices.

As the global market evolves, the wood industry must navigate supply chain complexities and respond to international demand fluctuations.

There is a growing need for machinery that can be customized and adapted to various production requirements, offering flexibility to wood industry enterprises.

Strategic Partnerships and Collaboration

Engineering firms like NÕMM INSENERID OÜ play a pivotal role in driving innovation and providing tailored solutions that address the unique challenges of the wood industry.

Collaborations between industry and academia are essential for fostering innovation and training the next generation of mechanical engineers specialized in wood processing technologies.

Comments (0)