5 reasons to choose diamond drilling for your next project

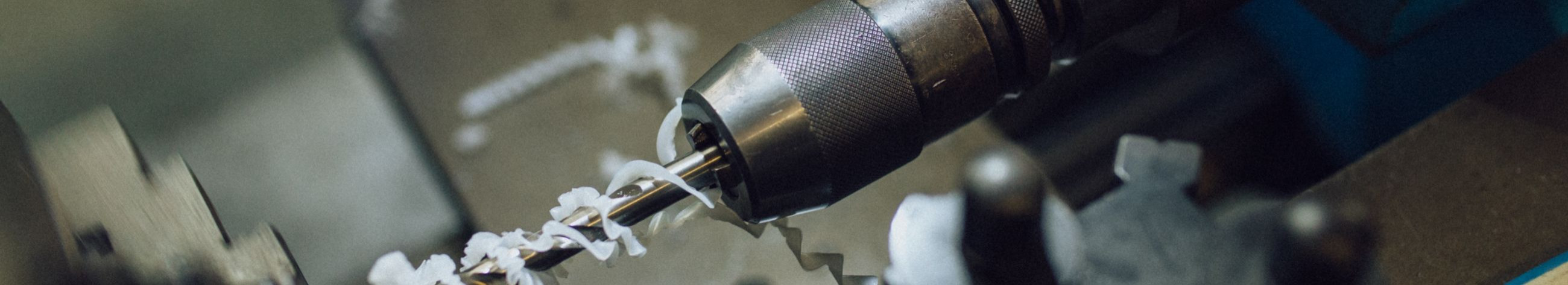

Diamond drilling is a cutting-edge technique that employs diamond-impregnated drill bits to create precise holes and openings in a variety of materials. Known for its accuracy and efficiency, diamond drilling is the go-to method for projects that require the highest level of precision.

Unlike traditional drilling methods that can cause cracks and structural damage, diamond drilling operates with minimal vibration, preserving the integrity of the surrounding material. This method stands out for its ability to deliver clean, accurate cuts with a finish that requires little to no additional work.

Reason 1: Unmatched Precision

In the construction industry, precision is paramount. Inaccurate cuts can lead to structural weaknesses, increased material waste, and additional labor costs. Diamond drilling eliminates these concerns by providing exact, clean cuts every time.

With diamond drilling, the level of control is unparalleled. The precision of the diamond bit allows for exact drilling to specified depths and diameters, making it ideal for creating openings for plumbing, electrical work, and ventilation systems.

Reason 2: Versatility Across Materials

Diamond drilling is not limited to a single material. It can be used on concrete, asphalt, glass, stone, and more, making it a versatile tool for a wide range of applications.

Whether you're working on a small residential project or a large commercial build, diamond drilling can be adapted to suit the specific needs of the job, ensuring optimal outcomes regardless of the complexity or scale.

Reason 3: Reduced Noise and Debris

Urban construction projects often face strict regulations regarding noise and waste management. Traditional drilling methods can fall short in these areas, leading to project delays and increased costs.

Diamond drilling is a quieter operation that produces less debris compared to conventional methods. This not only helps in complying with regulations but also reduces cleanup time and enhances the overall efficiency of the construction process.

Reason 4: Enhanced Safety

Safety is a top priority on any construction site. Traditional drilling methods can pose risks due to high levels of vibration and the potential for flying debris.

The precision and stability of diamond drilling reduce the risk of accidents, making it a safer choice for workers. Additionally, the reduced vibration minimizes the risk of structural damage, further ensuring the safety of the construction site.

Reason 5: Time and Cost Efficiency

Time is money in construction, and delays can be costly. Diamond drilling's speed and precision can significantly shorten project timelines, leading to faster completion and reduced labor costs.

By minimizing material waste and reducing the need for additional finishing work, diamond drilling can lead to substantial cost savings. Its efficiency also means fewer man-hours are needed, further reducing the overall cost of the project.

Comments (0)