The art of diamond sawing: precision meets durability

Diamond sawing is a specialized technique used in the construction industry to cut through hard materials with precision and efficiency. This method employs diamond-impregnated blades, which are renowned for their hardness and durability. The process is not only about cutting through concrete or stone but doing so with a level of accuracy that traditional sawing methods cannot match.

In the fast-paced world of construction, precision and durability are not just desirable, they are essential. The ability to make precise cuts quickly can significantly affect the timeline and budget of a project. Moreover, the durability of the cutting tools ensures that they can withstand the rigors of heavy-duty use without frequent replacement, saving time and resources.

The Science Behind Diamond Saw Blades

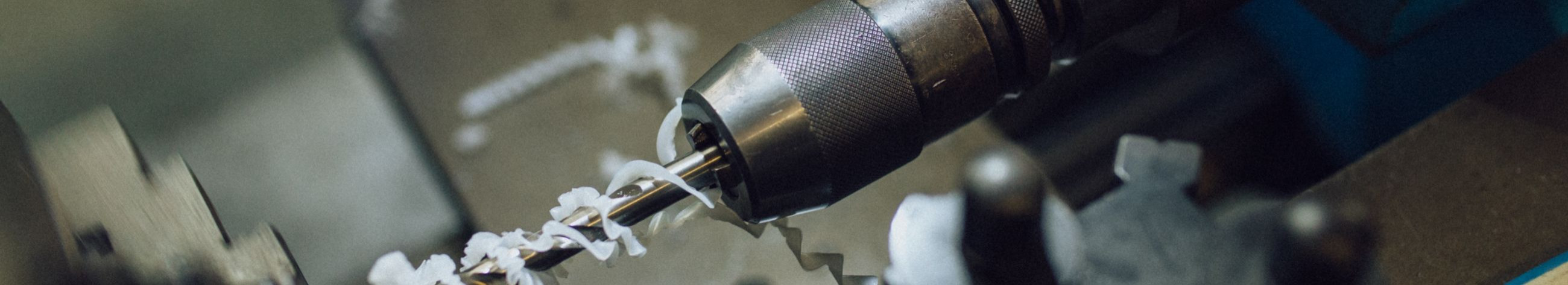

Diamond saw blades are composed of a steel core and a diamond segment. The segment contains synthetic diamonds mixed with metal powders, which are then sintered at high temperatures to form a solid bond. This unique composition allows the blades to maintain their cutting edge and withstand the heat generated during the sawing process.

Unlike traditional cutting tools that use teeth to tear through material, diamond blades grind away at the surface. The exposed diamonds on the edge of the blade act as an abrasive, cutting through hard materials with ease. This grinding action produces a smooth cut and reduces the likelihood of chipping or cracking the material being sawed.

Types of Diamond Sawing Techniques

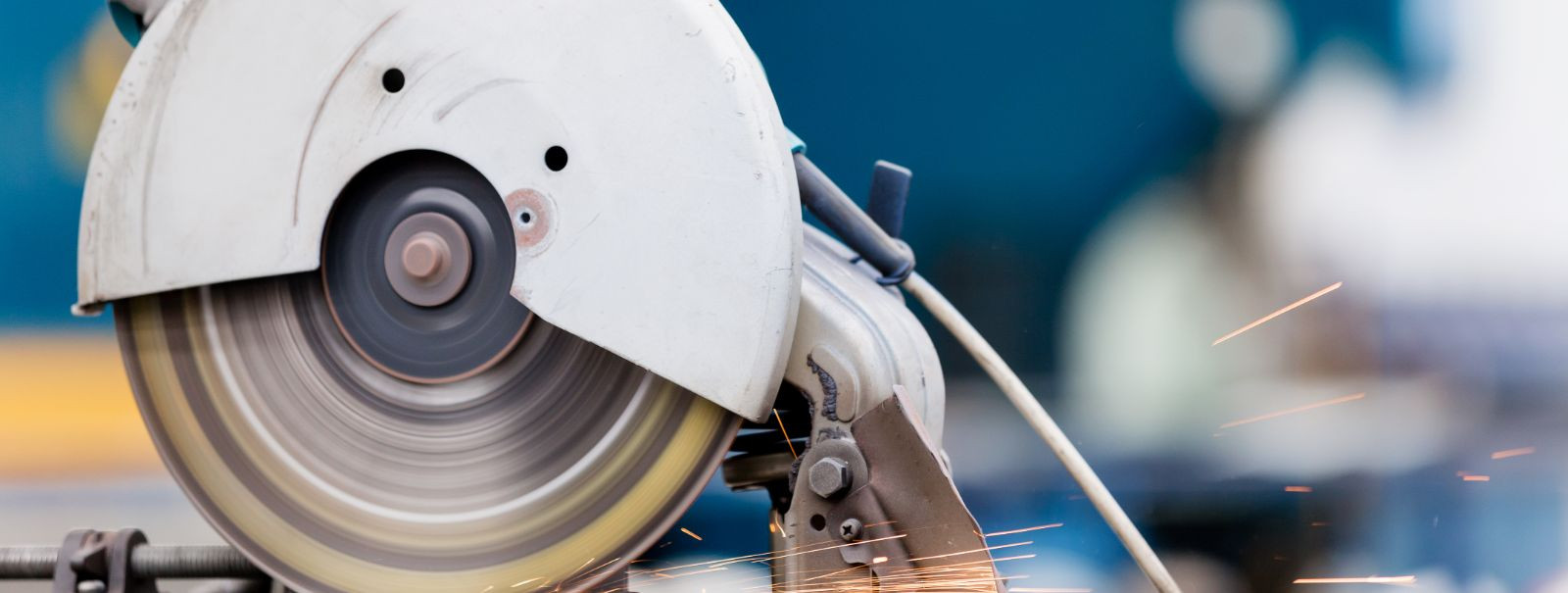

Wet sawing is a technique that involves the use of water to cool the blade and reduce dust. This method is ideal for indoor cutting or in situations where dust control is a priority. The water also helps to prolong the life of the diamond blade by minimizing friction and heat.

Dry sawing, on the other hand, does not use water and is suitable for outdoor applications where water supply is limited or where slurry disposal is a concern. While dry sawing is more convenient in some scenarios, it typically results in more dust and requires blades to be allowed to cool off periodically.

Hand-held saws offer flexibility and are ideal for smaller jobs or areas that are difficult to access. Rig-mounted saws, however, provide stability and are better suited for larger, more demanding projects that require straight cuts.

Applications of Diamond Sawing in Construction

Diamond sawing is extensively used in building renovation and demolition, where precision cuts are necessary to preserve structural integrity or to create openings for new features without causing unnecessary damage.

For infrastructure projects such as highways, bridges, and tunnels, diamond sawing is indispensable. It allows for precise cutting of thick concrete slabs and complex structures, ensuring that the components fit together perfectly during construction.

Modern architecture often involves complex designs that require intricate cutting. Diamond sawing provides the precision needed to bring these designs to life, whether it's for creating artistic patterns in flooring or cutting custom-shaped panels for façades.

Choosing the Right Diamond Sawing Equipment

When selecting diamond sawing equipment, it's important to consider the material to be cut, the desired speed of cutting, the level of precision required, and the overall scope of the project. These factors will determine the type of saw and blade needed for optimal performance.

The diamond sawing industry is constantly evolving, with new technologies emerging to enhance performance and efficiency. Innovations such as laser-welded diamond segments and vibration-dampening systems are just a few examples that have improved the capabilities of diamond sawing equipment.

Maintaining Diamond Sawing Equipment

To ensure the longevity of diamond saw blades, regular maintenance is crucial. This includes checking for wear, ensuring proper mounting, and following the manufacturer's guidelines for use. Proper care can significantly extend the life of a diamond blade, providing better value for the investment.

Even with the best maintenance practices, issues can arise. Being able to troubleshoot common problems such as uneven wear, loss of cutting speed, or excessive vibration can help quickly resolve issues and minimize downtime.

Comments (0)