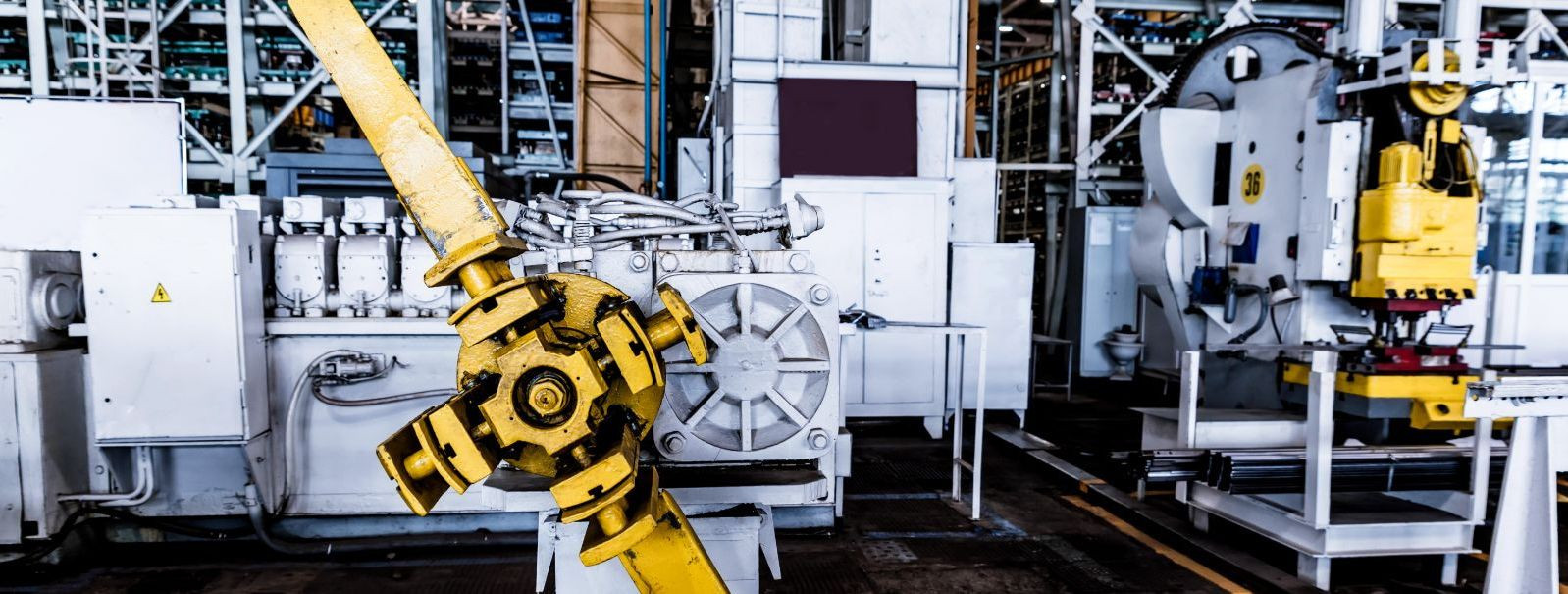

5 reasons why custom equipment can elevate your manufacturing process

In the competitive landscape of manufacturing, efficiency, precision, and innovation are not just goals—they are imperatives. Custom equipment can be a game-changer for manufacturers looking to elevate their processes. CREATES SYSTEM OÜ specializes in providing bespoke solutions that address the unique challenges and requirements of your manufacturing operations. Here are five compelling reasons why custom equipment is a strategic investment for your manufacturing process.

Enhanced Efficiency and Productivity

Every manufacturing process has its nuances. Custom equipment is designed to fit seamlessly into your specific production line, eliminating the need for makeshift adaptations. This perfect fit ensures that your operations run smoothly, with minimal interruptions.

Custom solutions are optimized for your production needs, which means they can help reduce material waste and enhance the throughput of your operations. By maximizing the use of resources, custom equipment can significantly improve your bottom line.

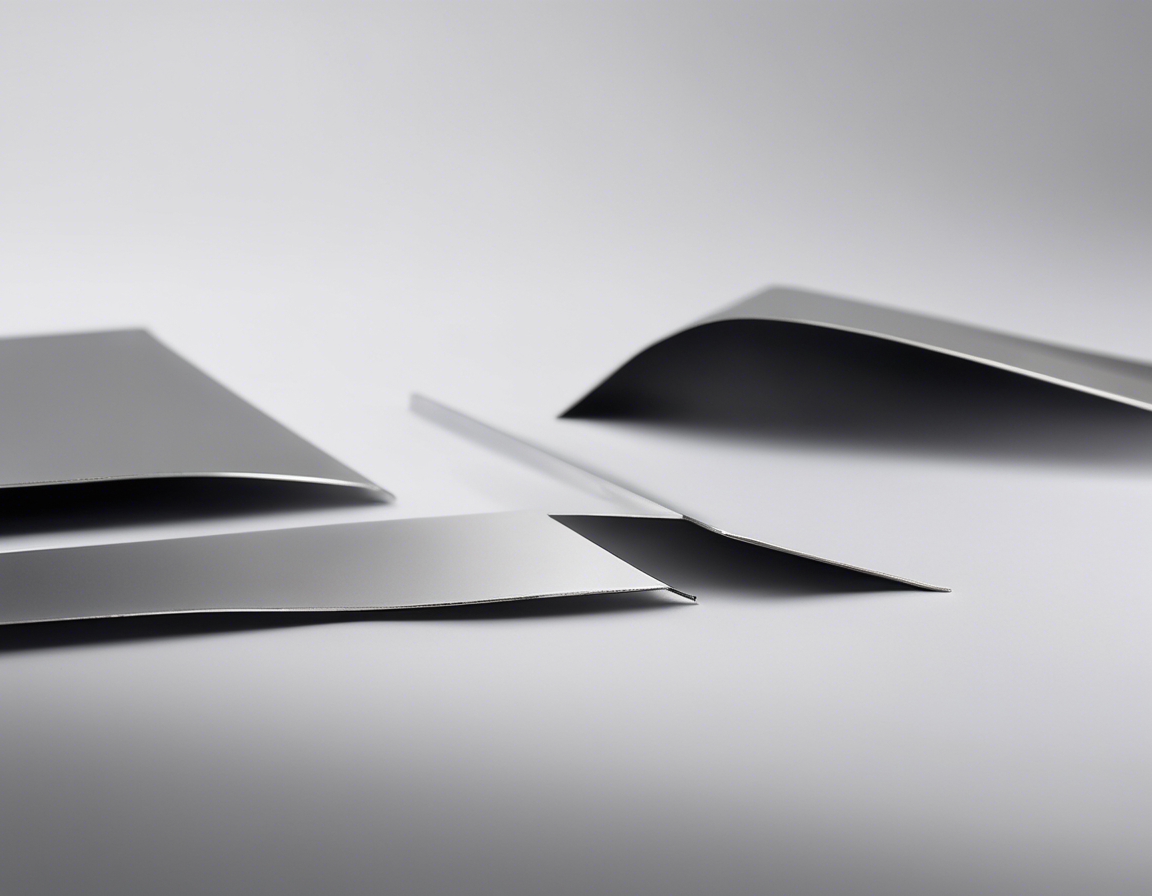

Improved Quality and Consistency

Custom equipment is engineered to meet the exact specifications required for your products. This level of precision ensures that each item produced meets the highest quality standards, which is essential in industries such as pharmaceuticals and food processing.

Consistency is key in manufacturing. Custom machinery can be designed to ensure that every batch or piece is identical, reducing the risk of defects and ensuring that your product quality remains high.

Greater Flexibility and Scalability

The ability to quickly adapt to market changes is crucial for any business. Custom equipment can be designed with flexibility in mind, allowing for easy adjustments and modifications to accommodate new products or processes.

As your business grows, your manufacturing needs will evolve. Custom equipment can be designed to scale with your operations, ensuring that you can increase production capacity without the need for entirely new machinery.

Long-Term Cost Savings

Custom equipment is built to last and tailored to your specific operational conditions, which can lead to less wear and tear and reduced downtime for maintenance. This reliability translates into cost savings over time.

While the initial investment in custom equipment may be higher, the long-term benefits often outweigh the costs. Durable, high-quality custom machinery can deliver a substantial return on investment through its extended lifespan and operational efficiencies.

Competitive Advantage

Custom equipment can provide you with the means to innovate and differentiate your products from competitors. By enabling unique manufacturing processes, you can offer something in the market that others can't easily replicate.

In highly regulated industries, meeting standards and regulations is not optional. Custom equipment can be designed to ensure compliance, helping you avoid costly fines and maintain a strong reputation.

Comments (0)