From sketch to steel: the journey of designing industrial equipment

The journey from a conceptual sketch to the final steel structure of industrial equipment is a complex process that involves a series of meticulously planned steps. Each phase of the design and manufacturing process is critical to ensure the final product meets the exacting standards required by manufacturing businesses, industrial engineers, and project managers. In this post, we will explore the intricate journey of designing industrial equipment, highlighting the expertise and precision that CREATES SYSTEM OÜ brings to each project.

Understanding Client Needs

The design process begins with an initial consultation to understand the client's vision, operational requirements, and the challenges they face. This is a collaborative effort where communication is key to ensuring the equipment will meet all the necessary specifications and industry standards.

Following the consultation, a detailed requirement analysis is conducted. This involves gathering all the technical data, production capacity, and environmental considerations that will influence the design of the equipment.

Conceptualization and Design

The first tangible step in the design process is sketching the idea. This is where creativity meets functionality, as designers draft the initial concepts that will eventually be transformed into robust industrial equipment.

With the help of advanced software, the initial sketches are developed into 3D models. These models allow for virtual simulations that can predict how the equipment will perform under various conditions, enabling designers to make informed decisions early in the design process.

Engineering and Technical Specifications

Selecting the right materials is crucial for the durability and performance of the equipment. Factors such as strength, corrosion resistance, and suitability for the intended application are all considered during this phase.

Engineering calculations are performed to ensure the equipment can withstand the stresses and loads it will encounter during operation. This step is vital for the safety and longevity of the equipment.

Prototyping and Testing

Before full-scale production begins, a prototype is built. This allows for hands-on testing and the opportunity to make any necessary adjustments to the design.

Performance testing of the prototype is essential to verify that the equipment meets all functional requirements. It's a rigorous process that ensures reliability and efficiency.

Final Design and Production Planning

Based on the results of the prototyping and testing phase, the design is refined. This may involve tweaking dimensions, materials, or even the overall concept to ensure the best possible outcome.

Once the final design is approved, production planning begins. This includes scheduling, resource allocation, and setting up the manufacturing environment to optimize the production process.

Manufacturing and Assembly

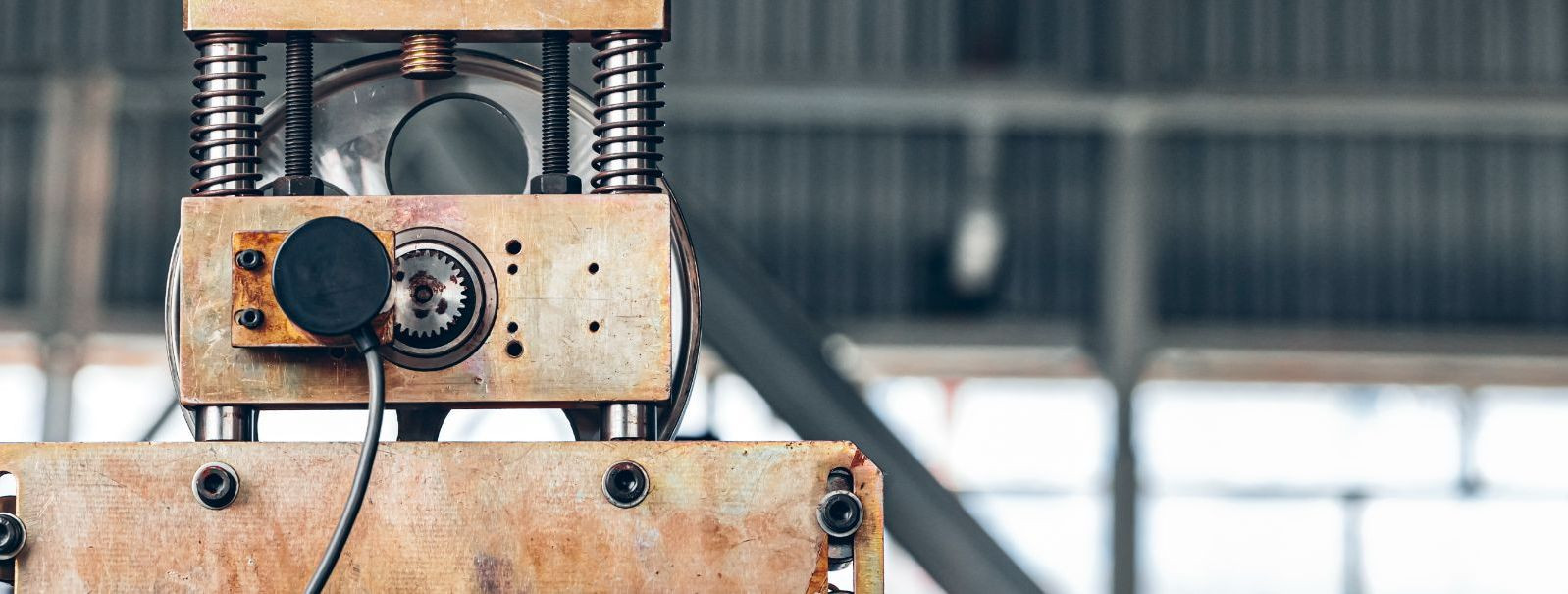

The manufacturing phase involves various fabrication processes, each chosen for its ability to produce parts that meet the precise specifications of the design. Advanced machinery and skilled technicians work in tandem to bring the design to life.

Throughout the manufacturing process, quality control and assurance are paramount. Each component is inspected and tested to ensure it meets the high standards expected by our clients.

Installation and Commissioning

The final step in the journey is the on-site installation of the equipment. CREATES SYSTEM OÜ's team of experts ensures that the installation process is smooth and that the equipment is set up to operate at peak performance.

After installation, operational testing is conducted to confirm that everything is functioning as intended. Once these tests are successfully completed, the equipment is handed over to the client, marking the end of its journey from sketch to steel.

Comments (0)