Precision matters: the importance of cnc turning in modern engineering

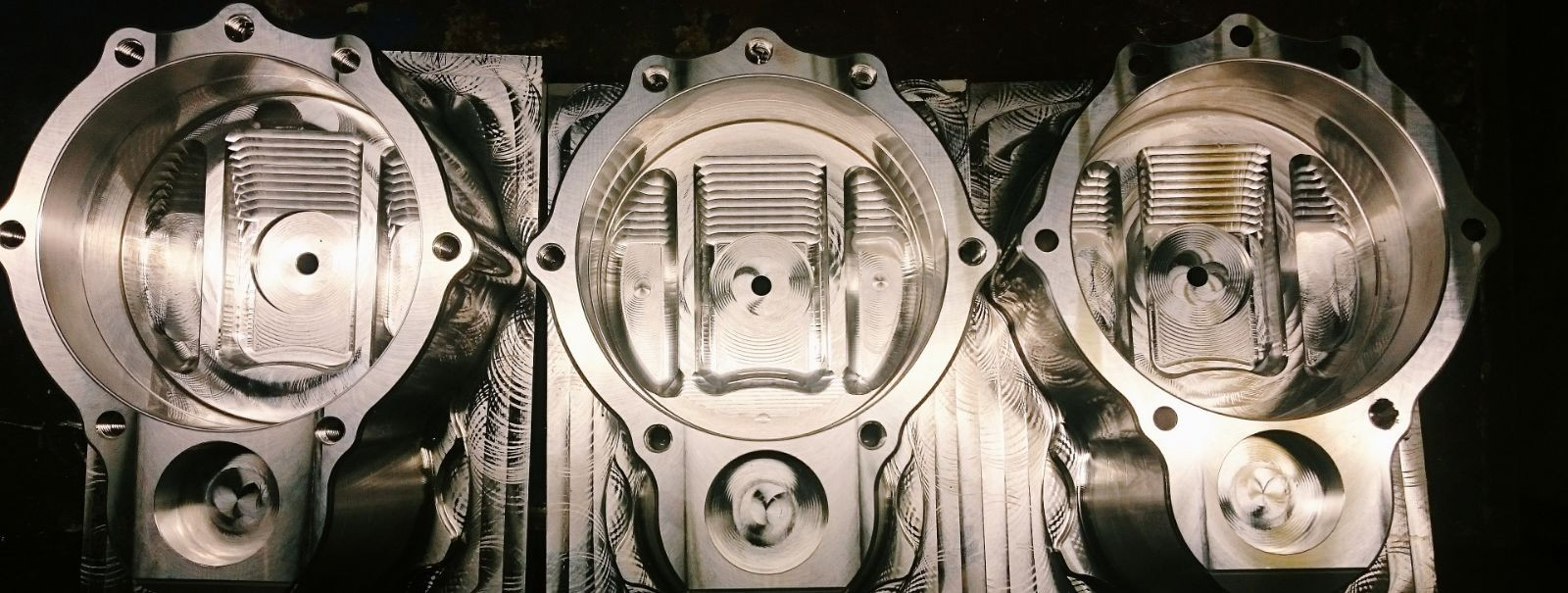

CNC turning is a manufacturing process where computer-controlled machines rotate a workpiece against a cutting tool to remove material and create precise cylindrical parts. This method is a cornerstone of modern manufacturing, offering unparalleled accuracy and efficiency.

From its inception in the 1950s, CNC turning has evolved significantly. The integration of computer technology has transformed it from a manual, labor-intensive process to a highly automated, precision-oriented operation.

The Role of CNC Turning in Modern Engineering

CNC turning is critical in industries where precision is non-negotiable, such as aerospace, automotive, and medical devices. It is used to create components like engine parts, surgical tools, and complex fasteners.

Compared to traditional machining, CNC turning offers greater precision, repeatability, and the ability to produce complex shapes with tight tolerances. It also allows for faster production times and lower costs over the long term.

Understanding the CNC Turning Process

The CNC turning process begins with precise programming to ensure that the final product meets exact specifications. Advanced software is used to design parts and simulate the machining process before actual production.

A wide range of materials can be machined using CNC turning, including metals, plastics, and composites. The choice of cutting tools and inserts is critical to achieving the desired finish and tolerances.

Quality control is integral to CNC turning, with various inspection methods employed to ensure each part meets stringent standards. Precision is the hallmark of CNC turning, making it indispensable for high-stakes engineering projects.

Technological Advancements in CNC Turning

New CNC turning centers come with advanced features like multi-axis capabilities, live tooling, and automated loading systems, which expand the possibilities of what can be manufactured.

Software advancements have streamlined the CNC turning process, enabling more complex designs and better integration with CAD/CAM systems. Automation has also led to increased productivity and consistency.

Material science plays a significant role in CNC turning, with ongoing research into new alloys and composites that can withstand extreme conditions while maintaining precision.

Choosing the Right CNC Turning Partner

When selecting a CNC turning partner, factors such as experience, equipment capabilities, and a track record of quality are paramount. It's essential to choose a partner that understands the demands of your industry and can deliver consistently precise results.

SKARCON MACHINING OÜ stands at the forefront of CNC turning technology, offering state-of-the-art solutions tailored to the needs of modern engineering. With a focus on precision, reliability, and innovation, we are the partner of choice for businesses seeking the highest standards in CNC machining.

Comments (0)