The art of cad design: from concept to reality

Computer-Aided Design (CAD) has revolutionized the way we create and manufacture products. From its rudimentary beginnings as simple drawing tools, CAD has evolved into a sophisticated suite of solutions that enable designers and engineers to visualize, simulate, and analyze complex designs before they are ever built.

CAD is an indispensable tool in modern engineering and design. It allows for the creation of more accurate, detailed, and standardized drawings, and provides a platform for collaboration among various stakeholders in the manufacturing process.

Understanding the CAD Design Process

The CAD design process begins with an idea. This conceptual phase is where creativity meets functionality, and where the initial parameters of the project are defined.

Using CAD software, designers translate ideas into tangible designs. This step involves drafting the basic shape and form of the component or product, considering factors such as materials, dimensions, and tolerances.

With the initial design in place, simulation tools within CAD software allow for testing and analysis. This can include stress tests, thermal analysis, and other simulations to predict how the design will perform in real-world conditions.

Based on the results of simulations, the design is refined. This iterative process continues until the design meets all the necessary criteria and specifications.

Advanced CAD Features for Complex Projects

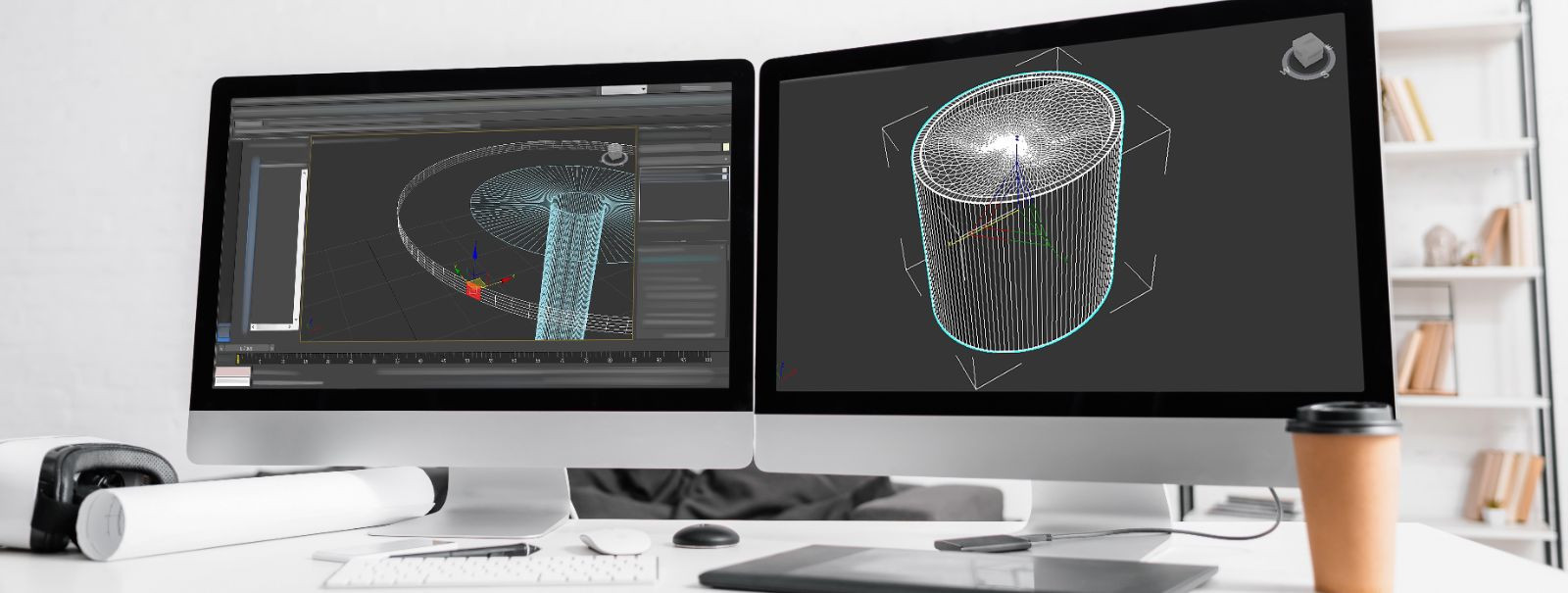

Advanced CAD systems offer 3D modeling capabilities that provide a realistic visualization of the final product, which is crucial for complex projects.

Parametric modeling allows designers to define specific constraints and relationships between different design elements, while direct modeling techniques offer more flexibility to quickly make changes to the design.

CAD is often integrated with Computer-Aided Manufacturing (CAM) and Computer-Aided Engineering (CAE) systems, creating a seamless transition from design to production and analysis.

Overcoming Challenges in CAD Design

As designs become more complex, managing and navigating the intricacies of CAD models can be challenging. Advanced software features and skilled CAD designers are essential to handle these complexities.

Precision and accuracy are paramount in CAD design, especially for industries like aerospace, automotive, and medical devices. CAD software must be capable of producing highly precise designs that adhere to strict industry standards.

Effective collaboration and communication are critical in the CAD design process, particularly when multiple stakeholders are involved. CAD software often includes tools to facilitate this collaboration.

Implementing CAD Designs into Manufacturing

Once a CAD design is finalized, the transition from digital to physical begins. This involves selecting the appropriate manufacturing techniques to bring the design to life.

Quality control measures and testing are integral to ensure that the manufactured product meets the design specifications and functions as intended.

For manufacturing businesses, the ability to scale production while maintaining quality and reproducibility is crucial. CAD designs must be optimized for these factors to ensure efficient manufacturing processes.

Comments (0)