Maximizing efficiency: tips for industrial filtration

Industrial filtration is a critical component of maintaining a clean, safe, and efficient production environment. It involves the removal of unwanted particles, contaminants, and substances from air, gases, and liquids, ensuring that machinery operates smoothly and products meet quality standards. Effective filtration systems protect equipment from damage, reduce downtime, and safeguard employee health.

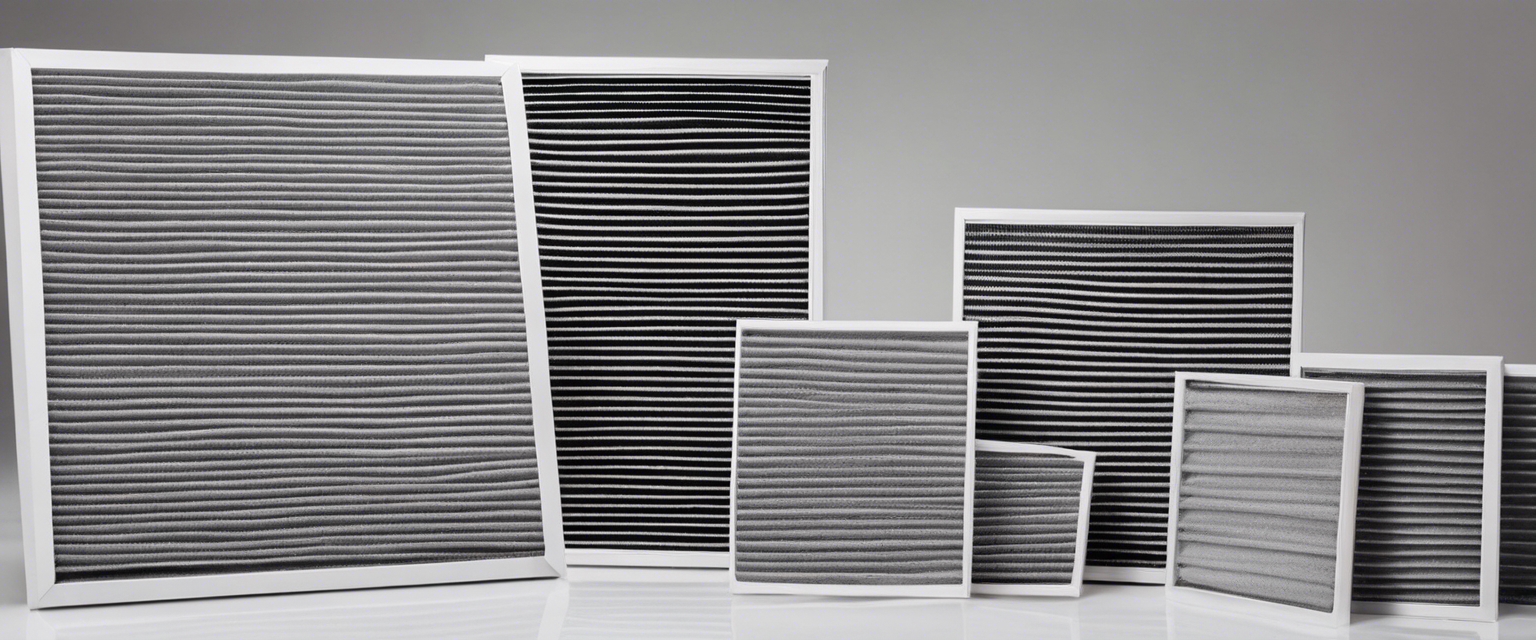

There are various types of industrial filters, including mechanical, cartridge, bag, HEPA, and activated carbon filters, each designed for specific applications and contaminants. Understanding the differences and applications of these filters is essential for selecting the right filtration solution for your needs.

Strategies for Maximizing Filtration Efficiency

Regular maintenance and inspections are paramount for ensuring filtration systems operate at peak efficiency. This includes cleaning or replacing filters as recommended by the manufacturer, checking for leaks or damage, and monitoring system performance.

The effectiveness of a filtration system largely depends on the filter media used. Factors such as particle size, chemical compatibility, and operating conditions must be considered when selecting the appropriate media to achieve optimal filtration.

Strategic placement of filters within the industrial process can significantly impact their efficiency. Filters should be positioned where they can capture the highest concentration of contaminants without impeding workflow or access to equipment.

Adopting energy-efficient practices, such as using filters with lower pressure drops and implementing variable speed drives, can reduce energy consumption and costs while maintaining filtration effectiveness.

Advancements in technology have led to the development of automated and smart filtration systems that can adjust to varying conditions, provide real-time data, and predict maintenance needs, further enhancing efficiency and reliability.

Cost-Effective Filtration Solutions

Investing in filters with a longer lifespan and higher durability can lead to cost savings over time, as they require less frequent replacement and can withstand harsher conditions.

Efficient filtration systems can help reduce operational costs by minimizing waste, extending the life of equipment, and lowering energy consumption.

While the initial investment in high-quality filtration systems may be higher, the long-term benefits, including reduced maintenance and operational costs, can justify the expense.

Environmental Considerations in Industrial Filtration

Adhering to environmental regulations is not only a legal requirement but also a responsibility towards the community and environment. Efficient filtration systems help industries comply with these regulations by controlling emissions and discharges.

Choosing filters made from eco-friendly materials can reduce the environmental impact of industrial processes. These materials are often recyclable or biodegradable, contributing to a more sustainable operation.

Implementing waste reduction strategies and recycling used filters when possible are important steps towards a more sustainable industrial filtration practice.

Comments (0)