5 trends shaping industrial automation in 2023

As we delve into 2023, industrial automation continues to evolve at an unprecedented pace, driven by technological advancements and the need for greater efficiency and productivity. In this blog post, we explore five key trends that are shaping the future of industrial automation and how they can transform operations for industrial and manufacturing facilities, commercial enterprises, and infrastructure projects.

1. Integration of Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing predictive maintenance by enabling systems to anticipate equipment failures before they occur. This proactive approach minimizes downtime and extends the lifespan of machinery.

AI-driven quality control systems are becoming more prevalent, offering unparalleled precision in detecting defects and ensuring product consistency.

AI and ML are also optimizing supply chain operations, providing insights that help reduce waste, improve delivery times, and lower costs.

2. Adoption of the Industrial Internet of Things (IIoT)

The IIoT connects machines and devices across facilities, enabling real-time data exchange and monitoring, which leads to smarter decision-making.

Smart sensors and devices collect critical data points that drive efficiency and productivity, allowing for more responsive and adaptive manufacturing processes.

With the IIoT, the vast amount of data generated can be analyzed to uncover patterns and insights, leading to more informed strategic decisions.

3. Increased Focus on Cybersecurity

As automation systems become more interconnected, the risk of cyber threats increases. Protecting these systems is paramount for operational security.

Developing and implementing robust security protocols is essential to safeguard against cyber attacks and protect sensitive data.

Employees play a critical role in cybersecurity. Training and awareness programs are crucial to ensure that staff can identify and respond to security threats effectively.

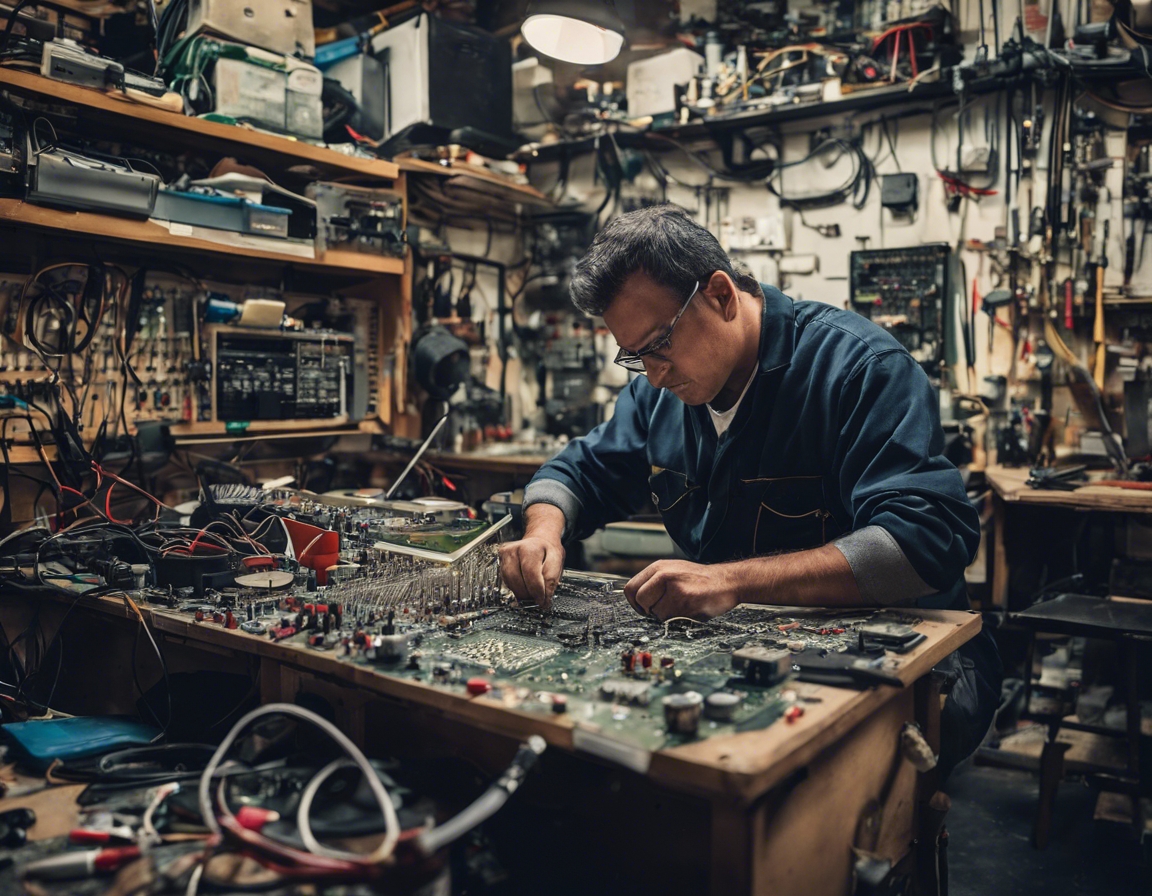

4. Collaborative Robots (Cobots)

Cobots are designed to work alongside humans, enhancing productivity and efficiency without compromising safety.

These robots are highly adaptable, capable of performing a variety of tasks, and can be easily reprogrammed for different applications.

Cobots are equipped with advanced safety features and are designed to operate in ergonomic harmony with human workers.

5. Sustainable and Energy-Efficient Solutions

There is a growing emphasis on sustainable practices within industrial automation, with a focus on energy-efficient technologies that reduce environmental impact.

Companies are increasingly required to comply with stringent environmental regulations, driving the adoption of green automation solutions.

Investing in sustainable technologies not only benefits the environment but also results in long-term cost savings and a strong return on investment.

Comments (0)