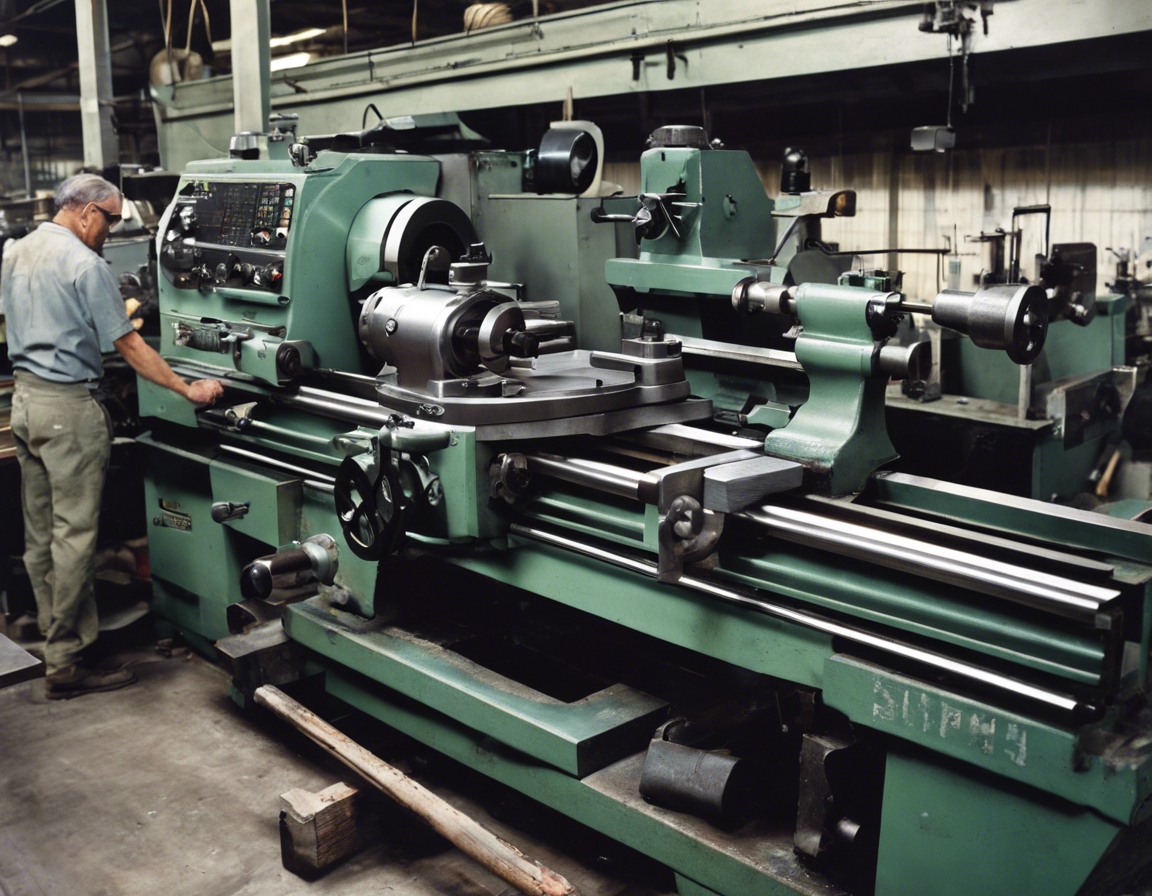

5 reasons why precision lathe work matters

Lathes are a cornerstone in the world of machining, known for their ability to shape metal and other materials with exceptional accuracy. A lathe operates by rotating the workpiece on its axis while various tools are applied to it to perform cutting, drilling, facing, and turning operations.

Precision in lathe work is not just about achieving the right dimensions; it's about ensuring the highest level of craftsmanship that goes into every component produced. In industries where the margin for error is negligible, the precision of lathe work becomes paramount.

Reason 1: Ensuring Product Consistency and Uniformity

When producing multiple parts, consistency is key. Precision lathe work ensures that each component is identical to the last, which is crucial for mass production and assembly lines where uniformity is a must.

The concept of interchangeable parts was revolutionary in manufacturing, and precision lathe work is at the heart of this concept. Accurate and consistent machining allows for parts to be swapped out and replaced without the need for individual fitting.

Reason 2: Extending the Lifespan of Machinery and Components

Components that fit together perfectly experience less wear over time, as there is minimal friction and stress on the materials. Precision lathe work contributes to the longevity of machinery and parts, ultimately saving costs on replacements and repairs.

Investing in precision machining means investing in the future of your equipment. By reducing the need for frequent maintenance, precision lathe work can significantly cut down on long-term operational costs.

Reason 3: Meeting Strict Industry Standards and Regulations

Many industries are governed by stringent quality standards that dictate the level of precision required for components. Precision lathe work ensures that these standards are met, which is essential for businesses to remain competitive and compliant.

From aerospace to medical devices, different industries have their own set of challenges and requirements. Precision lathe work allows manufacturers to meet these specific needs with accuracy and reliability.

Reason 4: Enhancing Performance and Efficiency

High-precision components are often critical for the optimal performance of machinery. Precision lathe work ensures that each part functions as intended, leading to better overall efficiency and productivity.

Well-machined parts not only perform better but can also contribute to energy savings. With less friction and better fit, machinery can operate more smoothly, reducing energy consumption and increasing output.

Reason 5: Supporting Innovation and Complex Designs

As technology advances, so does the complexity of designs and the need for precision. Precision lathe work is essential in bringing innovative ideas to life, allowing for the creation of components with intricate features and tight tolerances.

Every industry faces unique challenges that require custom solutions. Precision lathe work provides the flexibility and accuracy needed to tackle these challenges, delivering custom-fitted parts that meet the exact specifications of any project.

Comments (0)