The art of custom metal fabrication: a closer look

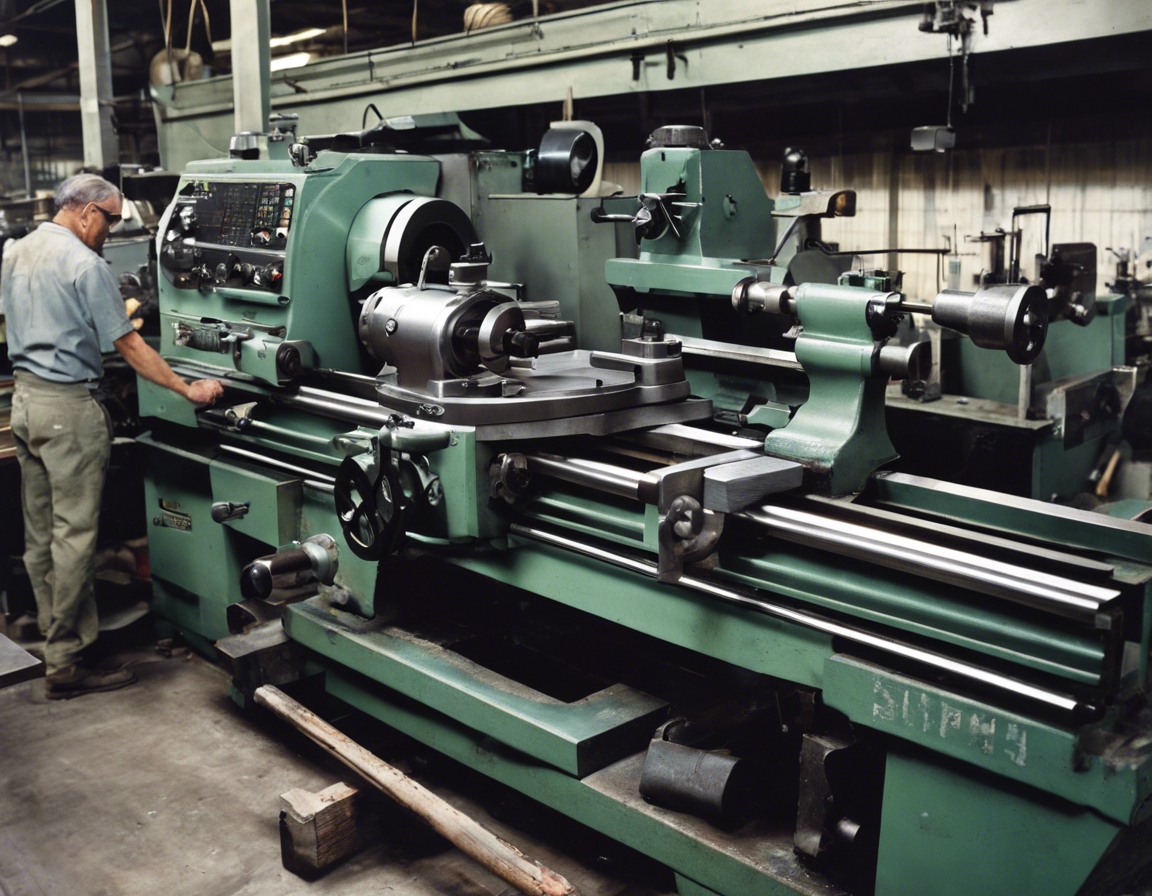

Custom metal fabrication is the process of designing, cutting, forming, and assembling metal structures from various metal parts and pieces. It's a complex service that requires a high level of skill, precision, and technical knowledge. Custom fabrication allows for the creation of bespoke components tailored to specific industrial, construction, or manufacturing needs.

Custom metal fabrication is integral to modern industry. It provides the backbone for structures, machinery, and vehicles across various sectors. The ability to create custom components means that businesses can achieve the exact specifications and performance they require for their operations.

The Custom Metal Fabrication Process

The first step in custom metal fabrication is the design phase. This involves using software to create detailed blueprints of the desired component. Engineers work closely with clients to ensure that the design meets all specifications and is optimized for manufacturing.

Once the design is finalized, the fabrication process moves on to cutting and forming the metal. This can be done through various methods such as laser cutting, punching, or shearing. The metal is then formed into the desired shape using techniques like bending, rolling, or stamping.

The final steps in the fabrication process are assembly and finishing. Components are welded or fastened together to create the final product. Finishing processes such as sandblasting, painting, or coating are applied to protect the metal and enhance its appearance.

Materials Used in Metal Fabrication

Steel is one of the most common materials used in metal fabrication due to its strength and versatility. Alloys such as stainless steel and carbon steel are also widely used for their specific properties like corrosion resistance and durability.

Aluminum is another popular material in metal fabrication. It's lightweight yet strong, making it ideal for applications where weight is a concern.

Besides steel and aluminum, other materials such as copper, brass, and various composites can be used depending on the requirements of the project.

Advanced Techniques in Metal Fabrication

Computer Numerical Control (CNC) machining is a process that involves using computers to control machine tools. CNC machining allows for high precision and complex shapes that would be difficult to achieve manually.

Laser cutting is a technique that uses a high-powered laser to cut materials. It is known for its accuracy, speed, and ability to cut complex shapes with a high-quality finish.

Robotic welding is used to automate the welding process, resulting in increased efficiency and consistency in the quality of the welds.

The Role of Technology in Metal Fabrication

Advanced software is used in the design and simulation of metal fabrication projects. This allows for the optimization of designs and the prediction of potential issues before production begins.

Automation plays a significant role in modern metal fabrication. It helps increase production speed, reduce costs, and improve the overall efficiency of the fabrication process.

Quality Control in Metal Fabrication

Quality control is crucial in metal fabrication. Adherence to industry standards and certifications ensures that the final products meet the required safety and performance criteria.

Inspection and testing are integral parts of the quality control process. These steps verify that the fabricated components conform to the design specifications and are free from defects.

Choosing the Right Metal Fabrication Partner

When selecting a metal fabrication partner, it's important to consider their experience and expertise in the field. A proven track record can give you confidence in their ability to handle your project.

The capacity and capabilities of a fabricator are also critical. They should have the necessary equipment and skilled workforce to meet your project's demands.

Good customer service and open communication are essential for a successful partnership. Your fabricator should be responsive to your needs and provide clear updates throughout the fabrication process.

Comments (0)