Ensuring safety: the importance of electrical shield inspections

Electrical shields are integral components of a robust electrical system, serving as a protective barrier against electromagnetic interference (EMI) and ensuring the safety and efficiency of electrical operations. These shields are commonly found in various forms, such as metallic enclosures, grounding systems, and shielded cables.

Regular inspections of electrical shields are essential to maintain the integrity of electrical systems. They help identify potential issues before they escalate into serious problems, ensuring the safety of occupants and the longevity of the electrical infrastructure.

The Risks of Neglecting Electrical Shield Inspections

Ignoring the condition of electrical shields can lead to a myriad of risks, including electrical fires, equipment failure, and exposure to harmful EMI. These hazards not only pose a threat to safety but can also result in significant financial losses due to downtime and repairs.

Without regular inspections, electrical shields may deteriorate over time, compromising the system's performance and safety. This neglect can lead to compliance issues with safety regulations, potentially incurring legal liabilities and insurance complications.

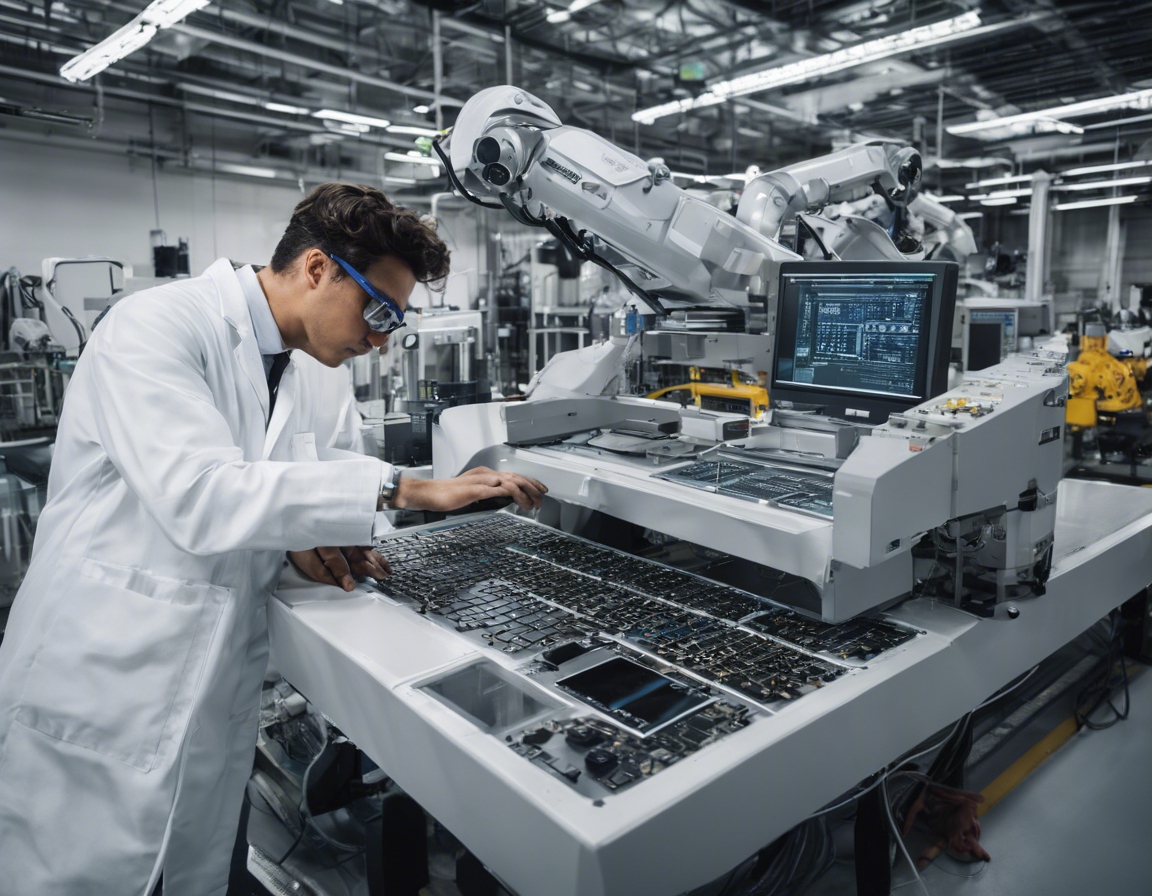

Components of a Comprehensive Electrical Shield Inspection

Visual inspections are the first step in assessing the condition of electrical shields. They involve a thorough examination for signs of wear, corrosion, or damage that could impact the shield's effectiveness.

Electrical continuity tests ensure that the shields are properly grounded and capable of conducting fault currents safely to the ground, preventing potential electric shock incidents.

Insulation resistance testing measures the integrity of the shield's insulation, which is crucial for preventing accidental contact with live electrical components and avoiding EMI issues.

Best Practices for Electrical Shield Inspections

The frequency of electrical shield inspections should be determined based on the environment, usage, and manufacturer's recommendations. High-risk areas may require more frequent inspections to ensure continuous safety.

While some basic inspections can be performed by trained personnel, it is advisable to engage professional services for a comprehensive evaluation. Experts like ELIGERO OÜ possess the necessary tools, expertise, and knowledge of current standards to conduct thorough inspections.

Adhering to the latest electrical standards is vital for ensuring safety and compliance. Regular training and updates are necessary to keep up with evolving regulations and technologies.

Advanced Technologies in Electrical Shield Inspections

Thermal imaging cameras can detect hot spots and thermal anomalies that may indicate issues with electrical shields, allowing for non-invasive and efficient inspections.

Ultrasonic testing is another advanced technique that can identify defects in electrical shields by detecting high-frequency sound waves reflected from flaws or discontinuities.

Drones equipped with specialized sensors can access hard-to-reach areas, providing a comprehensive view of electrical shields without the need for scaffolding or ladders, enhancing safety and efficiency.

Comments (0)