Innovative trends in metal fabrication

Metal fabrication is a cornerstone of modern industry, providing the essential components and structures that support a wide range of sectors, from construction to automotive manufacturing. As the demand for high-quality, durable metalwork solutions grows, so too does the need for innovative approaches that can meet the specific needs of industrial companies, construction firms, and architects.

Advanced Technologies in Metal Fabrication

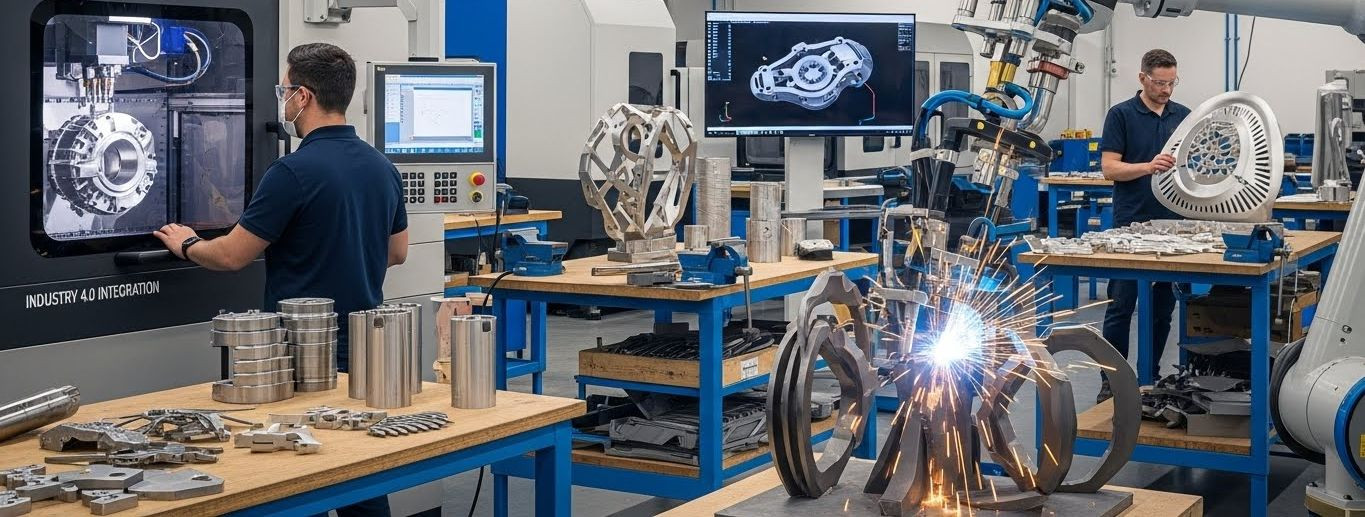

The integration of automation and robotics in metal fabrication has revolutionized the industry. Automated systems enhance precision and efficiency, reducing human error and increasing production speed. Robotics are particularly beneficial in repetitive tasks, allowing skilled workers to focus on more complex aspects of fabrication.

Additive manufacturing, commonly known as 3D printing, is transforming metal fabrication by enabling the creation of complex geometries that were previously impossible or too costly to produce. This technology allows for rapid prototyping and customization, offering significant advantages in terms of design flexibility and material usage.

Laser cutting and precision machining are at the forefront of metal fabrication technology. These methods provide unparalleled accuracy and speed, allowing for intricate designs and tight tolerances. The use of lasers in cutting metal reduces waste and improves the overall quality of the finished product.

Sustainable Practices in Metal Fabrication

As environmental concerns become increasingly important, the metal fabrication industry is adopting more sustainable practices. The use of eco-friendly materials, such as recycled metals and alloys, is gaining traction. These materials not only reduce the environmental impact but also often offer superior performance characteristics.

Energy efficiency is a critical consideration in modern metal fabrication. Innovative processes that minimize energy consumption, such as advanced welding techniques and optimized production workflows, are becoming standard practice. These methods not only reduce costs but also contribute to a more sustainable industry.

Customization and Flexibility in Design

Modular fabrication is an emerging trend that offers significant advantages in terms of flexibility and scalability. By producing components in a modular fashion, companies can easily adapt to changing project requirements and reduce lead times. This approach is particularly beneficial in construction and industrial applications.

The use of digital design tools and prototyping is enhancing the ability to customize metal fabrication projects. Advanced software allows for precise modeling and simulation, enabling architects and engineers to visualize and refine designs before production begins. This reduces errors and ensures that the final product meets exact specifications.

Enhanced Quality Control Measures

Real-time monitoring systems are becoming an integral part of quality control in metal fabrication. These systems provide continuous feedback on production processes, allowing for immediate adjustments and ensuring that quality standards are consistently met. This proactive approach minimizes defects and enhances overall product reliability.

Advanced testing techniques, such as non-destructive testing (NDT) and computer-aided inspection, are critical for maintaining high quality standards in metal fabrication. These methods allow for thorough evaluation of materials and components without compromising their integrity, ensuring that only the best products reach the market.

Comments (0)