Maximizing the lifespan of your heavy equipment

Heavy equipment is the backbone of industries such as construction, agriculture, and mining. Ensuring that this equipment remains operational over the long term is not just a matter of maintenance, but a comprehensive approach to its care and handling. In this post, we'll explore the strategies and practices that can help maximize the lifespan of your heavy equipment.

Understanding the Importance of Regular Maintenance

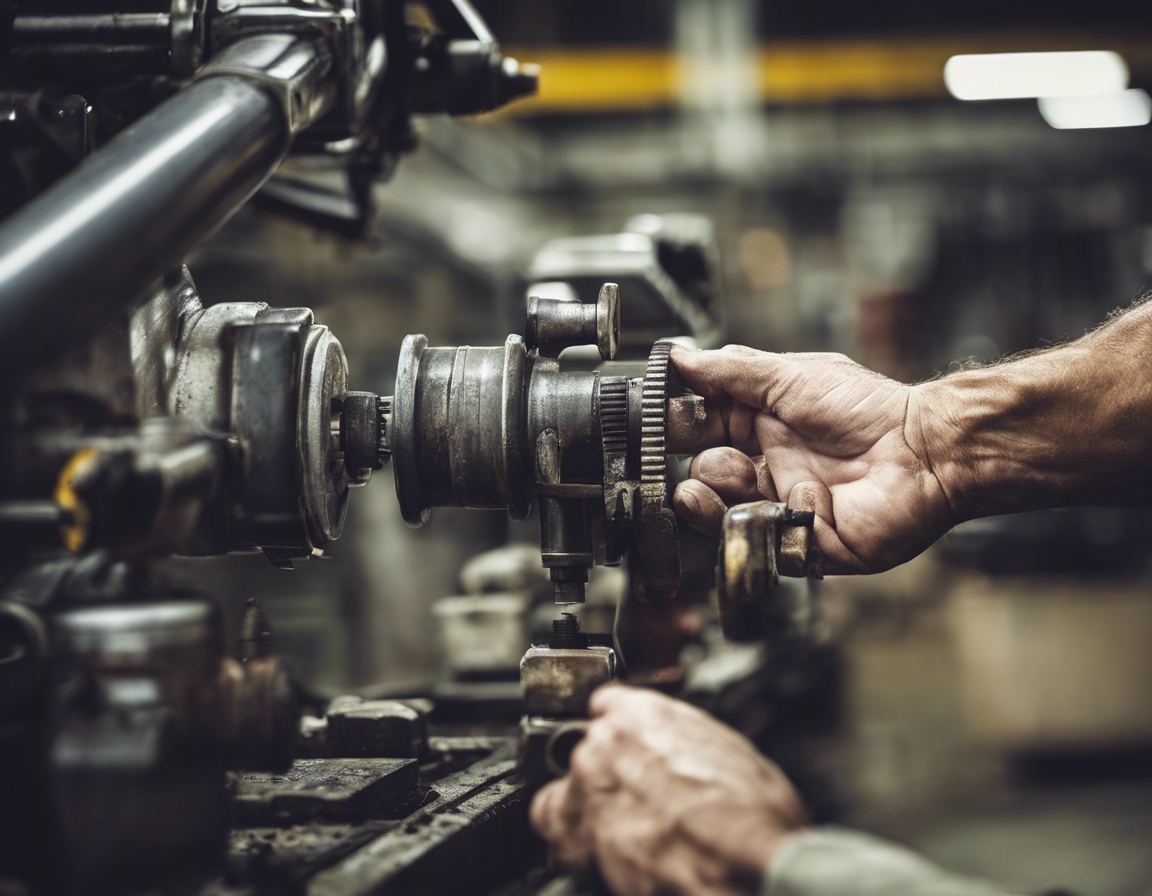

Preventative maintenance is the first line of defense against wear and tear. This includes regular checks and the timely replacement of parts before they fail. By proactively addressing potential issues, you can prevent costly downtime and extend the life of your machinery.

Scheduled maintenance, as recommended by the manufacturer, is crucial. Adhering to a maintenance schedule ensures that all components of your heavy equipment are in optimal condition and can significantly reduce the likelihood of unexpected breakdowns.

Keeping detailed records of maintenance and repairs can help track the health of your equipment. Monitoring systems can also provide real-time data on equipment performance, allowing for more informed maintenance decisions.

Choosing the Right Parts and Attachments

Investing in high-quality parts may come at a higher initial cost, but it pays off in the long run. Quality parts are less likely to fail and can withstand the rigors of heavy use.

Ensuring that parts and attachments are fully compatible with your equipment is essential. Ill-fitting components can cause damage and reduce the efficiency of your machinery.

While aftermarket parts can be cost-effective, authentic parts are typically designed to meet the exact specifications of your equipment. Choosing authentic parts can lead to better performance and longevity.

Operating Practices for Equipment Longevity

Operator error is a significant cause of equipment damage. Comprehensive training programs can ensure that operators use machinery correctly and safely, reducing the risk of accidents and wear.

Adopting best practices in equipment handling, such as avoiding overloading and using the correct techniques, can minimize stress on the machinery and extend its lifespan.

Common mistakes, such as ignoring warning signs or pushing equipment beyond its limits, can lead to premature wear. Awareness and adherence to operational guidelines are vital.

Storage and Protection Strategies

Protecting your heavy equipment from harsh environmental conditions can prevent rust, corrosion, and other damage. Proper storage solutions are an investment in the longevity of your machinery.

Implementing security measures to prevent theft and vandalism is also crucial. This includes secure storage facilities and the use of tracking devices.

For equipment that is not in regular use, long-term storage practices such as proper lubrication and covering can prevent deterioration.

Professional Inspections and Services

Regular inspections by expert technicians can uncover issues that may not be apparent to the untrained eye. These professionals can provide insights and recommendations that are invaluable for maintaining equipment health.

Knowing when to seek professional help can save time and money. If you're unsure about a repair or maintenance task, it's often best to consult with an expert.

Establishing a relationship with a trusted supplier, like PARTS PLACE OÜ, ensures that you have access to quality parts and expert advice when you need it. This partnership can be a key factor in maximizing the lifespan of your heavy equipment.

Comments (0)