Top maintenance tips to avoid costly repairs

Maintaining heavy equipment is crucial for construction companies, agricultural enterprises, mining operations, and independent contractors. Proper maintenance not only ensures the reliability and efficiency of machinery but also prevents costly repairs down the line. In this post, we'll explore top maintenance tips that can save you time and money.

Understanding the Importance of Regular Maintenance

Neglecting regular maintenance can lead to significant downtime and expensive repairs. It's essential to understand that the cost of preventive maintenance is far less than the cost of major repairs caused by neglect.

Regular maintenance extends the life of your equipment and ensures it performs at its best. This means more efficient operations and a better return on your investment.

Essential Maintenance Tips

Conduct thorough inspections of your equipment regularly. Look for signs of wear, damage, and potential issues that could lead to equipment failure.

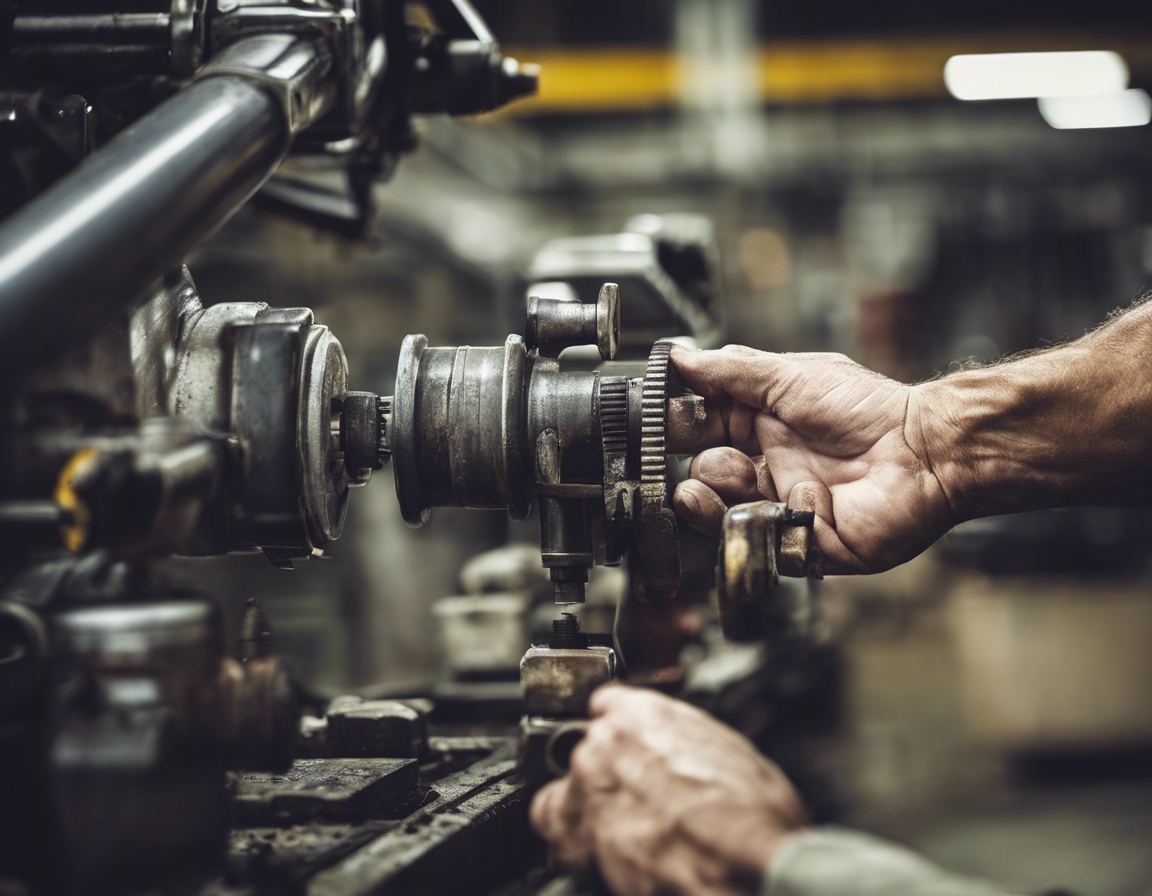

Keep your equipment clean and well-lubricated. Dirt and debris can cause premature wear, while proper lubrication reduces friction and wear on moving parts.

Regularly check and replace fluids and filters as needed. Clean fluids and filters are essential for the proper functioning of engines and hydraulic systems.

Identify and replace wear and tear parts before they fail. This includes items like belts, hoses, seals, and bearings.

Inspect and maintain electrical systems, including batteries, alternators, and starters, to prevent electrical failures.

Hydraulic systems are vital to heavy equipment. Regularly check for leaks and maintain proper fluid levels to ensure smooth operation.

Keep software up to date and calibrate equipment as necessary to optimize performance and prevent malfunctions.

Implementing a Preventive Maintenance Schedule

Develop a preventive maintenance schedule tailored to your specific equipment and operational needs.

Keep detailed records of all maintenance activities. This helps in tracking the health of your equipment and planning future maintenance.

Ensure that your team is properly trained to perform maintenance tasks. Well-trained personnel can identify potential issues before they become major problems.

Choosing Quality Spare Parts

Using low-quality spare parts can lead to more frequent failures and repairs. Invest in high-quality parts to ensure the longevity of your equipment.

Partner with reliable suppliers who provide quality spare parts. A trustworthy supplier can be a valuable asset in maintaining your equipment's health.

Professional Maintenance and Repair Services

Some maintenance tasks require professional expertise. Know when to call in experts to handle complex repairs and maintenance.

Establish a relationship with a service provider who understands your equipment and can provide quick and efficient maintenance and repair services.

Comments (0)