SEROMAR OÜ current status

This company's branding has already reached 15,970 peopleand his is followed by 38 Storybook users.On average, the company has been rated 4.7 points.and commented 10 times.

Tegevusaruanne 2024

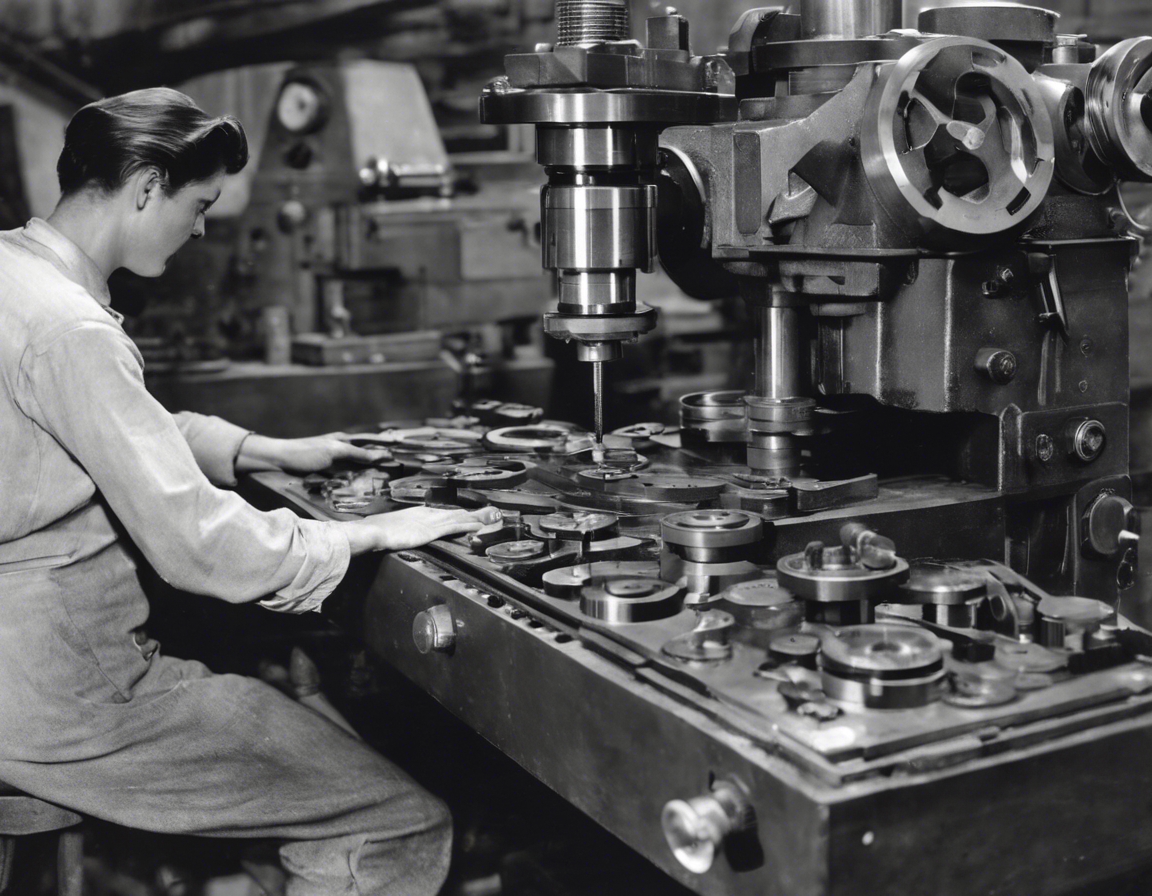

OÜ Seromar põhitegevusalaks on metalli töötlemine, s.h treimis- ja freesimistööd. Ettevõtte müügitulu 2024. aastal oli 763 942 eurot (2023. a. 1 037 611 eurot). Ettevõte teenis 2024. aastal kasumit 7 865 eurot (2023. a. 797 eurot). 2024. aasta lõpus oli lepinguliste töötajate arv 9 inimest, sh 2 juhatuse liiget. 2025. aastal planeerib ettevõte suurendada müügitulu ja parandada majandustulemust. Eesmärgiks on turu laiendamine Euroopa Liidu liikmesriikidesse.

Comments (0)