Maximizing efficiency with advanced hydraulic systems

Hydraulic systems are the lifeblood of many industries, providing the necessary power and control to operate a vast array of machinery. From the construction site to the factory floor, these systems have evolved significantly over the years, leading to the advanced hydraulic systems we see today.

Hydraulics play a pivotal role in modern industry, offering unparalleled power density and control for a variety of applications. The ability to lift, push, pull, and press with precision makes hydraulics indispensable in sectors such as automotive, construction, and agriculture.

As industries have advanced, so have the demands placed on hydraulic systems. The need for systems that are more efficient, reliable, and capable of handling complex tasks has driven innovation, resulting in today's sophisticated technologies.

Key Components of Advanced Hydraulic Systems

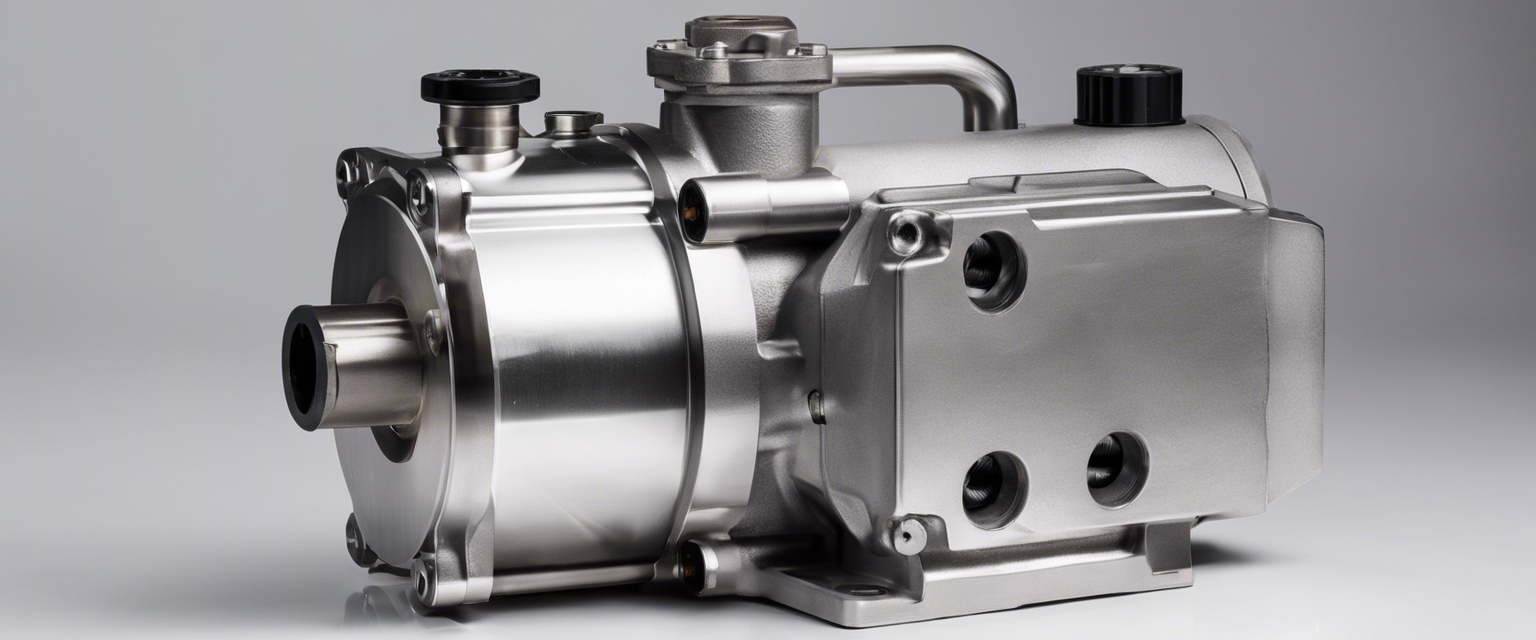

At the heart of any hydraulic system are the pumps and motors. These components have seen significant advancements, with modern designs offering higher efficiency and performance.

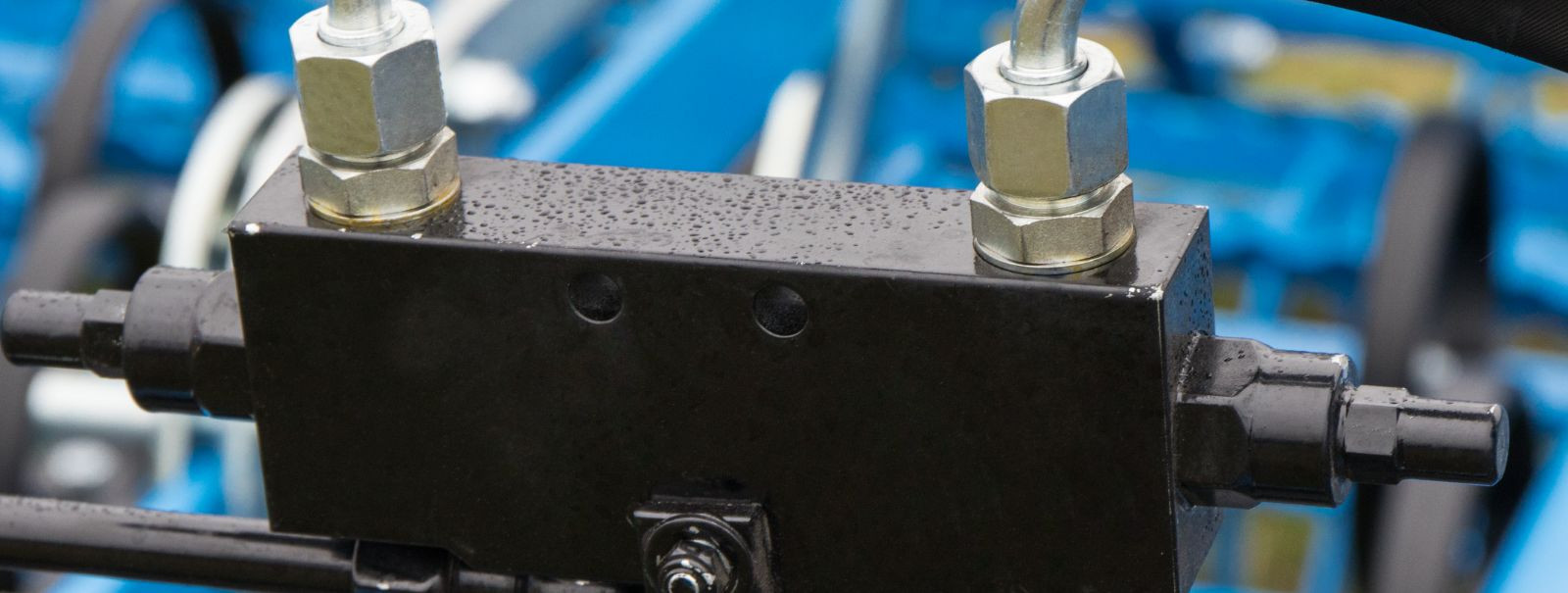

Valves control the flow and direction of hydraulic fluid, while actuators convert hydraulic energy into mechanical motion. Advances in these components have led to systems that are more responsive and precise.

Modern hydraulic systems are equipped with sensors and controllers that enable smarter operation. These technologies allow for real-time monitoring and adjustments, ensuring optimal performance.

Benefits of Advanced Hydraulic Systems

Advanced hydraulic systems are designed to do more with less, providing increased efficiency and productivity. This translates to faster cycle times and reduced operational costs.

With improved control systems, operators can achieve greater precision in their tasks, leading to better quality work and fewer errors.

Energy-efficient designs and technologies within hydraulic systems can significantly reduce power consumption, leading to lower energy bills and a reduced environmental footprint.

Optimizing Hydraulic Systems for Maximum Efficiency

Proper system design and configuration are critical for maximizing efficiency. This includes selecting the right components and ensuring they are matched to the application's requirements.

Maintenance is key to keeping hydraulic systems running at their best. A well-planned maintenance strategy can prevent downtime and extend the life of the system.

Integrating hydraulic systems with electromechanical systems can lead to even greater efficiencies and capabilities, offering the best of both worlds.

Technological Innovations in Hydraulic Systems

The integration of IoT technology into hydraulic systems, known as smart hydraulics, is revolutionizing the way these systems are monitored, controlled, and maintained.

Electro-hydraulic systems combine the power of hydraulics with the precision of electronic control, resulting in highly efficient and adaptable systems.

As environmental concerns become more pressing, the industry is responding with hydraulic systems that are not only more efficient but also more environmentally friendly, using biodegradable fluids and reducing emissions.

Comments (0)