The future of electromechanical equipment in industry

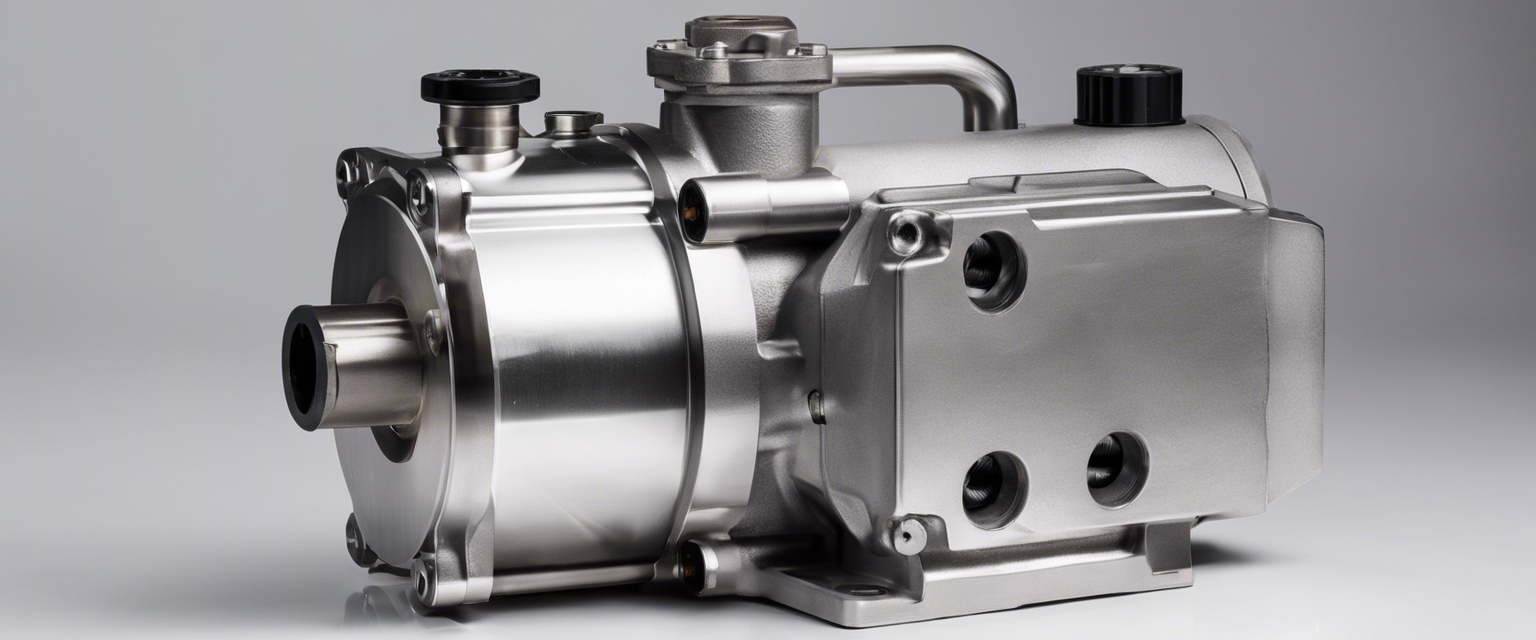

Electromechanical systems are the backbone of modern industry, combining electrical and mechanical processes to power everything from production lines to heavy machinery. These systems have evolved significantly over the years, becoming more sophisticated and integral to industrial operations.

Industries such as automotive, construction, mining, and agriculture rely heavily on electromechanical equipment for their daily operations. The precision, efficiency, and reliability of these systems are paramount for the success and competitiveness of businesses in these sectors.

Technological Advancements Shaping the Future

The integration of the Internet of Things (IoT) and Artificial Intelligence (AI) into electromechanical systems is revolutionizing the way industries operate. Smart sensors and intelligent algorithms enable predictive maintenance, real-time monitoring, and autonomous operation, leading to increased efficiency and reduced downtime.

Developments in materials science and component design are leading to lighter, stronger, and more durable electromechanical systems. These advancements not only improve performance but also extend the lifespan of equipment, reducing the need for frequent replacements.

As industries face pressure to reduce their environmental impact, energy efficiency and sustainability have become critical factors in the design and operation of electromechanical equipment. Innovations in this area are helping businesses meet regulatory requirements and achieve their sustainability goals.

Impact on Industry Sectors

The automotive industry is experiencing a shift towards electrification and automation, with electromechanical systems playing a key role in the development of electric vehicles (EVs) and autonomous driving technologies.

Electromechanical systems in construction and mining are becoming more robust and efficient, capable of handling the demanding environments and heavy loads characteristic of these industries.

Material handling and agricultural sectors are benefiting from the integration of advanced electromechanical systems that improve productivity and reduce labor-intensive processes.

Challenges and Considerations

Maintaining the complex electromechanical systems of today requires a deep understanding of both mechanical and electrical components. Reliability remains a top concern for industry professionals, as any downtime can lead to significant losses.

As technology advances, the need for skilled professionals who can operate and maintain these sophisticated systems grows. Continuous training and skill development are essential to keep pace with the evolving landscape.

Compliance with regulatory and safety standards is crucial for the operation of electromechanical equipment. As these standards evolve, businesses must adapt to ensure they meet the latest requirements.

Strategic Adaptation for Businesses

For businesses to remain competitive, investing in smart technologies and upgrading their electromechanical systems is essential. This not only improves operational efficiency but also positions them as leaders in their respective industries.

Working with expert providers like EUREST TEHNIKA OÜ, which specializes in optimizing hydraulic and electromechanical systems, can provide businesses with the necessary support and expertise to navigate the future of industry.

Adapting to the rapid changes in electromechanical technology requires a proactive approach. Businesses must stay informed and be willing to embrace new technologies to maintain their competitive edge.

Comments (0)